“rub-a-tex” insulation may also be

used as long as there is no heat

tape applied to the vent pipe. For

horizontal runs where water may

collect, wrap the vent pipe with

self-regulating 3 or 5 watt heat

tape. The heat tape must be

U.L. listed and installed per the

manufacturer’s instructions.

6. The minimum vent pipe length is

5 feet.

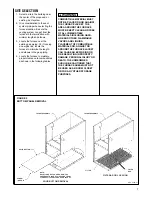

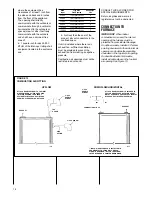

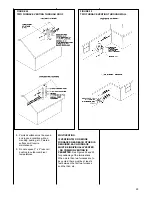

STANDARD INSTALLATIONS

The single-pipe system requires an

exhaust pipe only. Combustion air

may be taken from the furnace

installation area or ducted to the

furnace area from the outside.

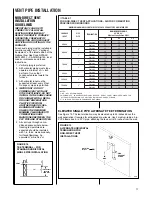

Size the exhaust pipe as specified in

Table 1. This table lists the maximum

allowable length in feet of the exhaust

pipe that may be used for all furnace

inputs as related to the number of

elbows required and the termination.

(See shaded area.)

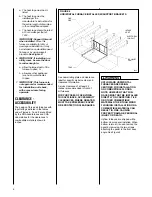

Vertical through-the-roof installations

do not require a vent termination. Use

2-in. PVC pipe extending a minimum

of 12 inches above the anticipated

level of snow accumulation. See

exhaust pipe requirements, Figure 20.

When 3-in. vent pipe is used from

furnace to the roof, reduce it to

2 inches before penetrating the roof.

A maximum of 18 inches of 2-in. pipe

may be used below the roof.

Horizontal vent terminations require a

2-in. PVC tee positioned 12 inches

from the outside wall. See exhaust

pipe requirements, Figure 21. When

3-in. pipe is used from the furnace to

the outside wall, reduce it to 2 inches

before penetrating the wall. A

maximum of 18 inches of 2-in. pipe

may be used inside the wall.

An alternate termination may be used

as shown in Figure 15 to clear

anticipated snow levels. The tee may

be raised up to 24 inches above the

wall penetration. Use two medium-

radius bend, 2-in. PVC elbows and a

length of 2-in. PVC pipe so that the

elbows are on 24-in. centers.

NON-DIRECT VENT TERMINATION

LOCATION REQUIREMENTS

MOISTURE IN THE COMBUSTION

PRODUCTS CONDENSES AS IT

LEAVES THE TERMINATION. THIS

CONDENSATE CAN FREEZE ON

EXTERIOR WALLS, UNDER THE

EAVES, AND ON SURROUNDING

OBJECTS. SOME DISCOLORA-

TION IS TO BE EXPECTED.

HOWEVER, IMPROPER LOCATION

18

OR INSTALLATION CAN CAUSE

STRUCTURAL OR EXTERIOR

FINISH DAMAGE TO THE

BUILDING.

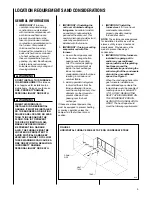

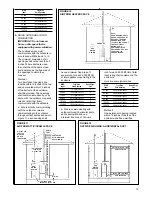

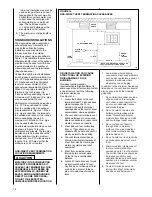

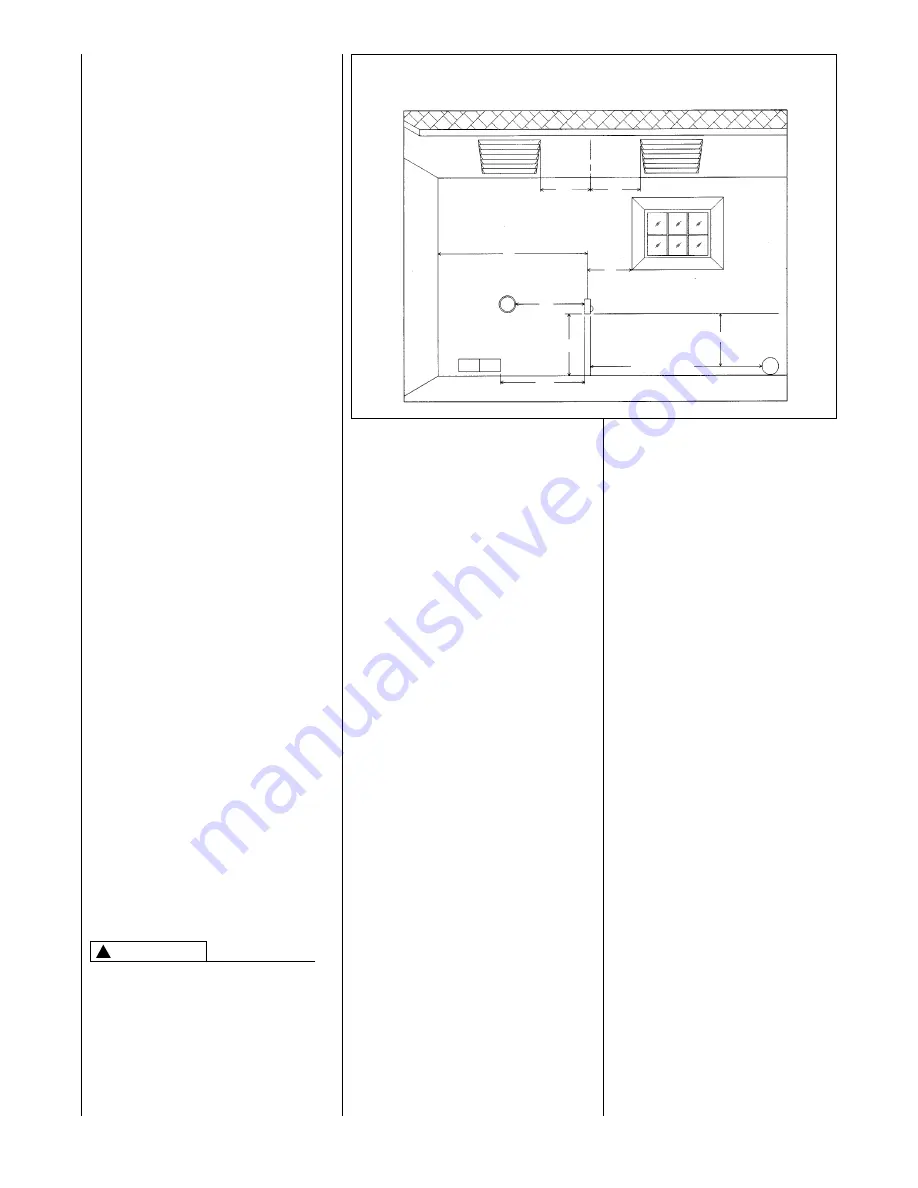

Non-direct venting location

requirements are slightly different in

some cases than direct venting. Install

a non-direct vent with the following

minimum clearances.

See Figure 16.

1. Locate the bottom of the vent

terminal at least 12 inches above

grade. Increase the 12-in.

minimum to keep the terminal

openings above the level of snow

accumulation, where applicable.

2. The vent shall not terminate over

public walkways or over an area

where condensate or vapor could

create a nuisance or hazard.

3. 4 feet below, 4 feet horizontally

from, or 1 foot above any door,

window soffit, under eave vent or

gravity air inlet to the building.

4. The vent terminal shall have a

minimum horizontal clearance of

4 feet from electric meters, gas

meters, regulators and relief

equipment.

5. 6 feet from an inside corner

formed by two exterior walls –

10 feet is the recommended

distance.

6. Locate it 3 feet above any forced

air inlet located within 10 feet.

Any fresh air or make-up air inlet,

such as for a dryer or furnace

area, is considered a forced air

inlet.

!

CAUTION

FIGURE 16

NON-DIRECT VENT TERMINATION CLEARANCES

I133

SOFFIT

VENTS

FRESH

AIR

INTAKE

*

NOTE: FOR DISTANCES OVER 10

*

NO

VERTICAL RESTRICTIONS APPLY.

INSIDE

CORNER

ELECTRIC

METER

10

*

RECOMMENDED

12

(

MIN.

UP TO10

*

*

4

*

4

*

3

*

4

*

4

*

4

*

6

*

7. Avoid areas where dripping

condensate may cause problems,

such as above planters, patios, or

adjacent to windows where

steam may cause fogging.

In addition to the minimum clearances

listed above, the vent location should

also be governed by the following

guidelines.

1. Do not terminate under any kind

of patio or deck. If running the

vent under a deck, insulate it to

insure no condensate freezes

and blocks the pipe.

2. Do not locate on the side of a

building with prevailing winter

winds. This will help prevent

moisture from freezing on walls

and overhangs (under eaves).

3. Do not extend vent directly

through brick or masonry

surfaces. Use a rust-resistant

sheet metal or plastic backing

plate behind vent.

4. Do not locate too close to shrubs

as condensate may stunt or kill

them.

5. Minimum vertical clearances of 1

foot are recommended for

overhangs up to 1 foot horizontal.

The vertical clearance should be

increased equally for each

additional increase in horizontal

overhang to a maximum vertical

clearance of 6 feet.

6. Caulk all cracks, seams and

joints within 6 feet horizontally

and above and below vent.

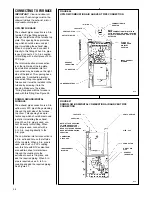

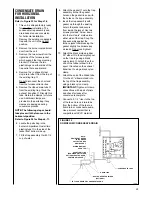

Содержание RGRA SERIES

Страница 38: ...38 FIGURE 45 HONEYWELL NO S9201E2001 CONTROL BOARD TWINNING CONNECTION SINGLE STAGE OPERATION I400...

Страница 39: ...39 FIGURE 46 HONEYWELL NO S9201E2001 CONTROL BOARD TWINNING CONNECTION TWO STAGE OPERATION I401...

Страница 40: ...40 FIGURE 47 UTEC NO 1012 920 1028 927 CONTROL BOARD TWINNING CONNECTION SINGLE STAGE OPERATION I398...

Страница 41: ...41 FIGURE 48 UTEC NO 1012 920 1028 927 CONTROL BOARD TWINNING CONNECTION TWO STAGE OPERATION I398...

Страница 42: ...42 FIGURE 49 JOHNSON CONTROLS G961DAJ 2401 CONTROL BOARD TWINNING CONNECTION SINGLE STAGE OPERATION I399...

Страница 43: ...43 FIGURE 50 JOHNSON CONTROLS G961DAJ 2401 CONTROL BOARD TWINNING CONNECTION TWO STAGE OPERATION I399...

Страница 62: ...62...

Страница 63: ...63...

Страница 64: ...64 Rheem Manufacturing Company Air Conditioning Division Fort Smith Arkansas CM 1197...