18

6. Maintenance

Cleaning

Caution: Before carrying out any adjustments or maintenance

ensure that the machine is isolated and disconnected from the

electricity supply.

1. To avoid a build-up of wood dust, regularly clean the thicknesser drive

gear using a brush or compressed air.

2. Lubricate all bearing points and chains regularly with a good quality

silicone spray such as CWA195. Keep flat belt free of oil and grease.

WARNING: If blowing sawdust, wear proper eye protection to

prevent debris from blowing into eyes.

3. Clean the thicknessing bed spindles on a regular basis to prevent the

build-up of wood chips and dust, lubricate with silicone spray. Do not use

ordinary oil as this will attract dust.

4. Keep infeed / outfeed tables and thicknessing bed free of resin. Clean

regularly with white spirit, then coat with a light film of silicone spray such

as Record Power CWA195 to enhance passage of workpiece on table

Fig 6.1

.

This machine will perform in conformity with the description contained

in this manual when installed, operated, maintained and repaired in

accordance with the instructions provided.

This machine must be checked periodically. Defective equipment (including

power cable) should not be used. Parts that are broken, missing, plainly

worn, distorted or contaminated, should be replaced immediately. Should

such repair or replacement become necessary, it is recommended that such

repairs be carried out by qualified persons.

This machine or any of its parts should not be altered or changed from

standard specifications. The user of this machine shall have the sole

responsibility for any malfunction which results from improper use or

unauthorised modification from standard specification, faulty maintenance,

damage or improper repair.

Kickback guards (A) (Fig 6.2)

Remove traces of resin as required. When lifted, the guards must drop back

into position by their own weight. Test their function before each use.

Feed rollers (B) (Fig 6.2)

Remove traces of resin monthly, when marks appear in the planer work-

pieces, or in the event of poor feed.

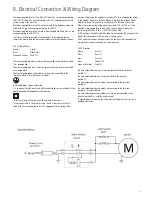

Transmission (Fig 6.3)

Ensure that chain A is sufficiently lubricated (Normal machine grease).

The friction wheel B is a consumable part and must be replaced as needed.

Fig. 6.2

A

B

Fig. 6.3

A

B

Fig 6.1

i

Kg

i

Kg

i

Kg

Содержание PT107

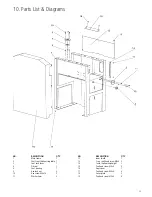

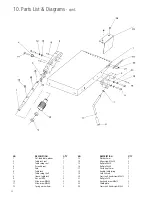

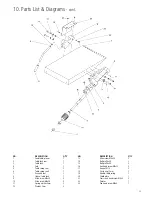

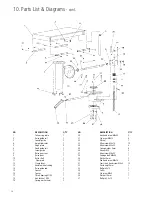

Страница 29: ...29 10 Parts List Diagrams cont ...

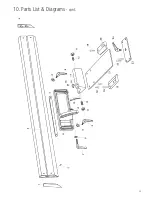

Страница 33: ...33 ...