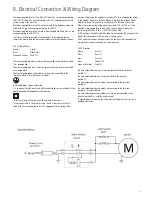

16

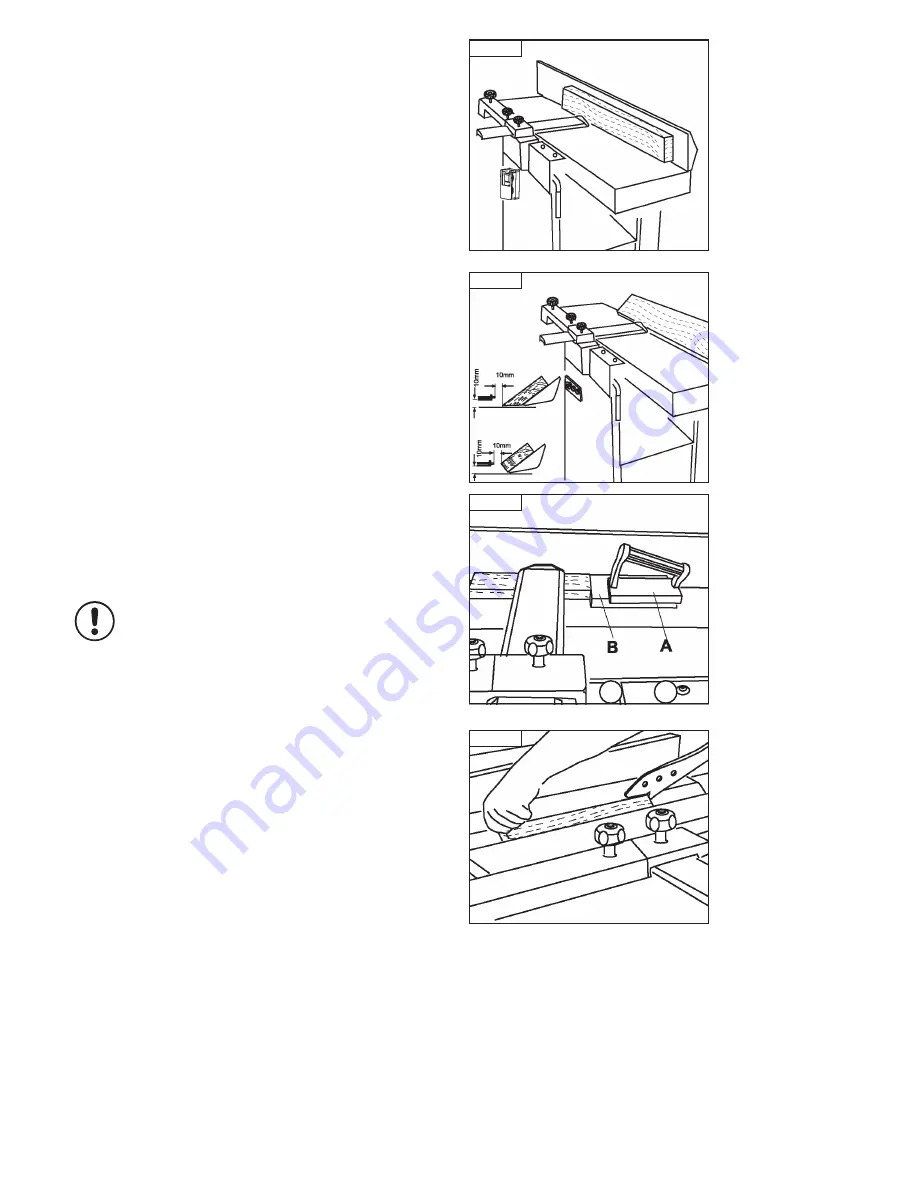

Edge planing

Allow the planer bridge guard to rest on the planer table and cover the

cutter block and allow for the width of the work-piece,

Fig. 5.11

.

Press the work-piece against the planer fence and guide evenly over the

cutter block.

As soon as the work-piece extends far enough into the out feed table,

place your left hand onto it and push it over the planer cutter block without

stopping

Tapering/edge beveling

In this mode, the longitudinal edges of a work-piece are beveled or tapered

at any required angles.

Set protective bridge guard,

Fig 5.12

.

Set the joiner fence to required angle and press the work piece against the

planer fence and guide evenly over the cutterblock.

To prevent the work-piece from slipping from the angled surface, press the

workpiece mainly against the fence and only lightly against the

planing table.

Planing/surfacing of small work-piece

When surfacing or planing small work-pieces, use pushing strips A and a

push block B,

Fig. 5.13

.

The push strip should not be thicker than the workpiece.

Tapering /beveling small work-piece

You must always use a special jig for beveling small, narrow work-pieces.

This device can also be used to bevel long work-piece.

Attach the jig to the planer fence. Set the planer bridge guard all the way

down and let the bridge guard contact the jig.

Note:

When surface planing, always feed the workpiece with a slow

and consistent feed rate. Feeding the workpiece too quickly will

reduce the quality of finish of the planed surface. Fine ridges or

marks across the width of the workpiece are an indication that

the feed rate is too fast.

Fig. 5.11

Fig. 5.12

Fig. 5.13

B

A

Fig. 5.14

5. Operation

i

Kg

Содержание PT107

Страница 29: ...29 10 Parts List Diagrams cont ...

Страница 33: ...33 ...