20

6 Maintenance

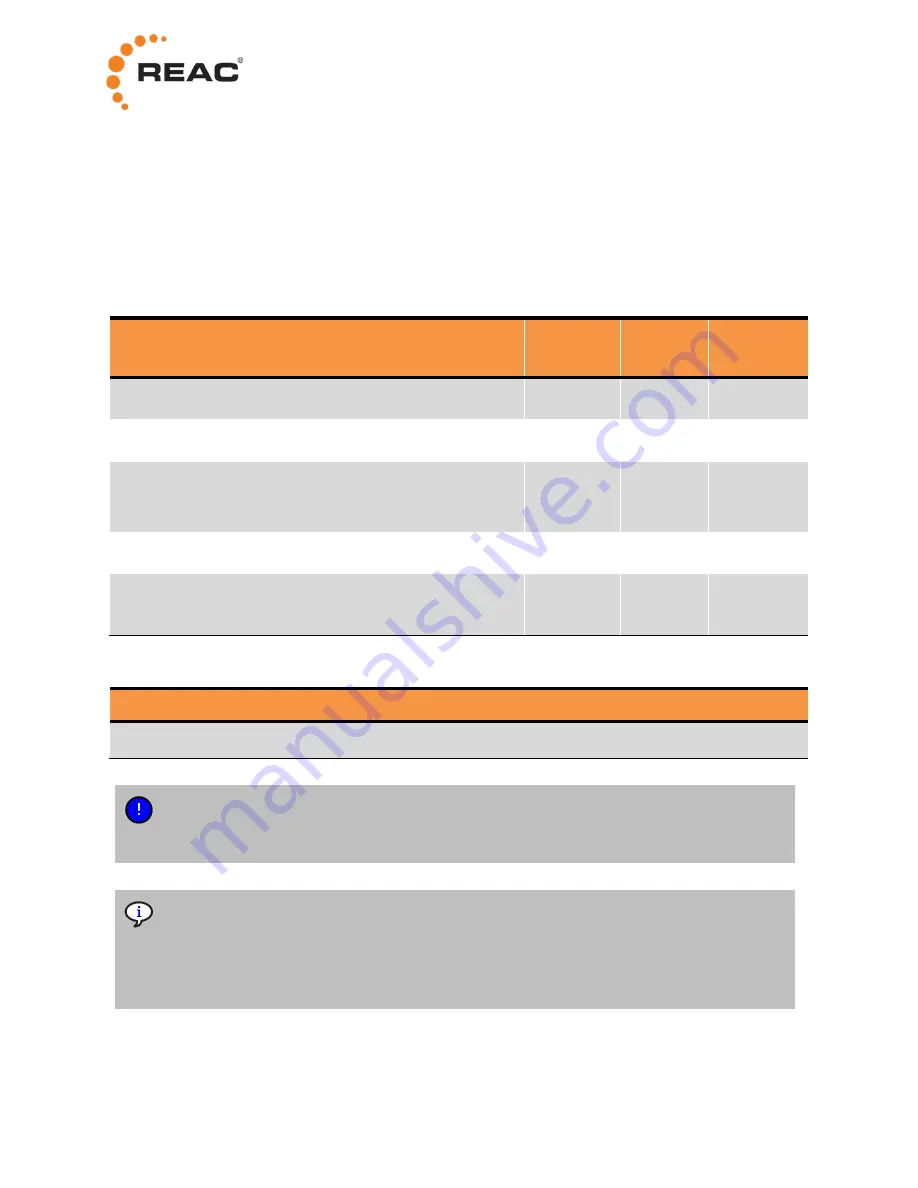

6.1 Service intervals

To ensure safe and proper operation, regular service is required. The service interval depends on the final

application and the number of actuator cycles.

Between the planned service points, regular inspection and maintenance should also be performed.

The following maintenance schedule is suggested:

Initially

Regularly

At planned

service

Control box

Make sure the control box is firmly fixed.

✓

✓

Cover

Check the plastic housing for mechanical damage (cracks).

✓

✓

✓

Cables

Make sure the cable that connects the actuator to the

control box is firmly affixed.

✓

✓

✓

Sealings

Check all O-rings for damage. Replace if necessary.

✓

✓

✓

Battery

Before use, make sure at least 1 green battery indicator

LED is lit on the hand control.

✓

✓

✓

6.2 Cleaning and disinfection

Cleaning instructions

Clean with a damp cloth or with a brush and water (water must not be under pressure)

Make sure all connectors are plugged during cleaning. This to prevent ingress of water.

Do not wash directly with a high-pressure cleaner.

Do not use a steam cleaner.

For disinfection, it is recommended to use soap or equal and clean with a damp cloth.

Cleaners and disinfectants must not:

•

be highly alkaline or acidic,

•

contain caustic agents,

•

change the structure of the surface of the plastic or the adhesives.

Содержание RCB10+

Страница 1: ...www reac se USER MANUAL RCB10 REAC CONTROL BOX...

Страница 30: ...28 Label example packaging...