14

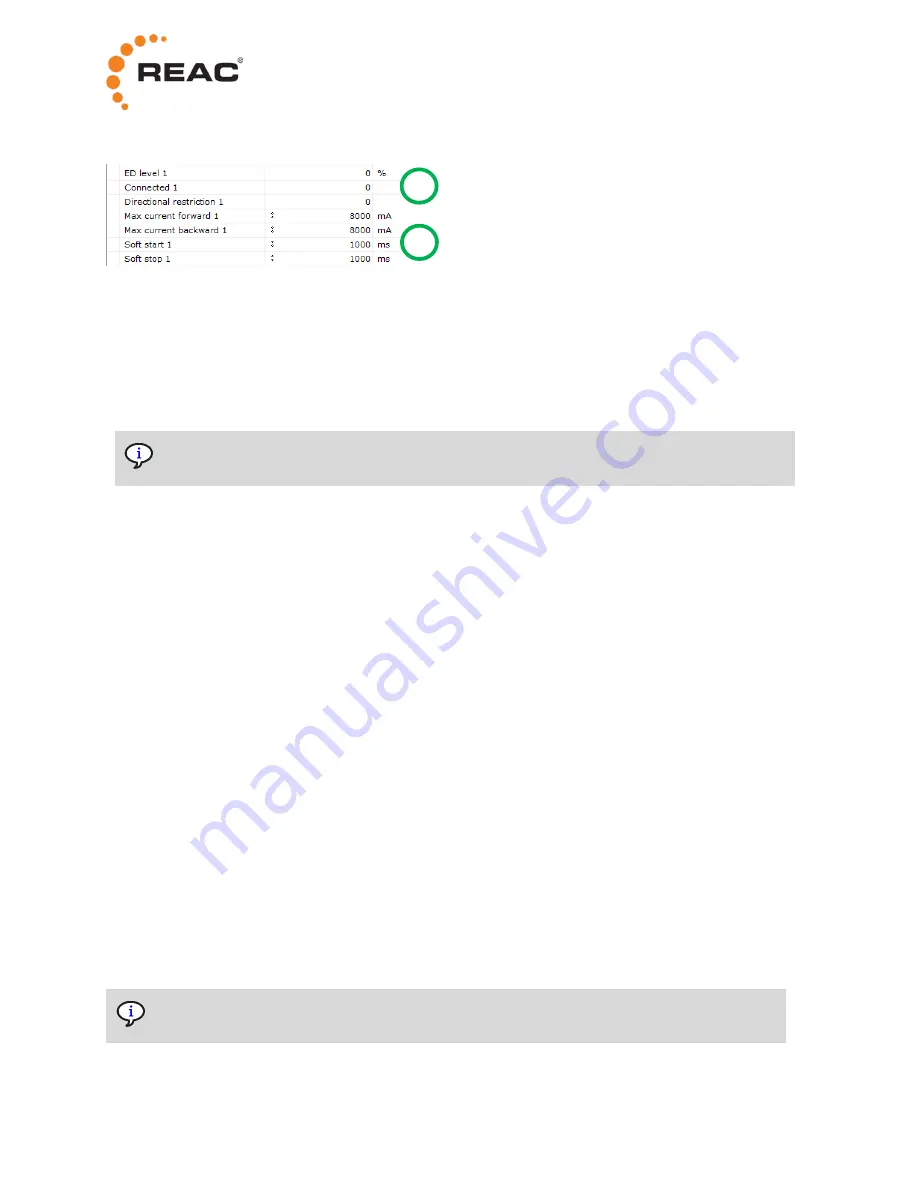

This image shows status registers and parameters in an expanded group.

1. Status registers are values that only can be read/viewed.

2. Parameters are values that can be changed. Parameters have a colon sign in front of the value.

To change a parameter, do the following:

1. Click the parameter value.

2. Enter a new value.

3. Press Enter. The new parameter value becomes effective immediately.

Parameters related to a channel will become effective after the next movement on that

channel.

5.2 RCB10+ parameters

To view and change the RCB10+ parameters, select the

C

icon and expand the groups.

The configurable parameters are available in the following groups:

•

DC out 1-4, one group per actuator channel

•

Operation

•

Usage

5.2.1 Soft start and soft stop

The soft start and soft stop parameters are used to adjust the start and stop ramps of the motor.

The parameters are set in time (ms). The time is between 0 to 100% PWM. Simply explained it works

more like a ramp speed setting, rather than an actual time setting. If a movement at 50% PWM is

demanded, that PWM level will be reached in half the time.

The

Soft start

and

Soft stop

parameters are available in the

DC out

groups.

5.2.2 Gain

If an actuator is considered to run too fast, either because it is built that way or as a result of the

mechanics around it, the speed can be limited by using the gain parameter. This can be needed, for

example, if the load is “helping” the actuator in one direction.

There is one parameter in each direction:

Gain forward

and

Gain backward

. The gain parameters are set

in % of the full pass-through of the signal.

The

Gain forward

and

Gain backward

parameters are available in the

DC out

groups.

Even if the parameter is called “gain”, this is not about amplification of the signal.

The maximum gain is the neutral 100%, meaning that it is only possible to reduce the signal.

2

1

Содержание RCB10+

Страница 1: ...www reac se USER MANUAL RCB10 REAC CONTROL BOX...

Страница 30: ...28 Label example packaging...