RG27/35/37 Operation • Service • Maintenance

44

Maintenance

Cutting Wheel & Teeth

Among the most critical elements of the stump cutter are the

cutting teeth. They are also the most subject to damage and

wear, as in the course of cutting stumps they may encounter

a numerous assortment of abra sives and objects in the

stump’s environment, such as dirt, stones, and occasionally a

large rock or buried scrap. The loss of and wear of teeth can

sig nifi cant ly impair the efficiency of a stump cutter and also

result in overexposure of other teeth, resulting in premature

failure or wear. There fore it is important to make frequent

observation of the con di tion of all of the cutting teeth, and

replace any missing and sig nifi cant ly worn teeth, as soon

as feasible. Read all of the instructions which follow before

changing cutting teeth.

Rayco Teeth

Rayco Manufacturing Inc. recommends only genuine Rayco

Cutting Tools for use on Rayco Stump Cutters and Forestry

Mowers. The use of non-Rayco cutting tools or cutting

wheels will void the machine warranty. Rayco’s cutting tools,

cutting wheels, and mower rotors are specifically designed

to provide optimum performance in many ways. The use of

non-Rayco parts will compromise this optimum performance.

• Safety: Rayco’s cutting tools are always attached with at

least two fasteners. This redundant fastening system is

far safer than those systems employing only one fastener.

Rayco’s cutting tools are also more visible than some of

the other cutting tools that are available. Some of the

cutting wheels available today are “transparent” which

can lead to an operator or bystander becoming confused

as to the actual limits of the cutter tool.

• Proper Balance: Rayco’s cutting wheels and mower

rotors are designed to achieve a dynamic balance that

avoids vibration. Using other cutting tools can set

up vibrations that will harm the machine’s structure &

reduce bearing life.

• Number of Teeth for Depth of Cut: Rayco’s cutter wheels

are designed to provide an economical cutting wheel

assembly solution. The teeth are spaced to provide a

maximum depth of cut for the number of teeth on the

wheel. Some of the wheels available today use a large

quantity of teeth to get the same depth of cut that a

Rayco wheel will achieve with half the teeth. While the

individual tooth cost may be less, the overall costs are

more. Additionally, having too many teeth in the stump

at any one time can lead to aggressive “grabbing” of the

stump, causing the stump cutter to violently hop. This

can cause injury to both man & machine.

• Tooth Projection: Rayco’s stump cutter teeth are

specifically designed to ensure that the carbide tip can

remove a clear “kerf” from the stump without the body

of the tooth ever contacting the stump. This concept

reduces drag, which maximizes the use of the machine’s

horsepower. This also reduces wear on the tooth body

and on the attachment hardware. Many of the other

cutting tool systems available today do not address this

important aspect of cutting.

• Cutting Tool Dimensions: Rayco’s stump cutting teeth

are carefully designed to have the proper size of carbide

tip. Carbide tips ultimately become dull, and using

large, oversized carbide tips will induce extreme impact

energies into the machine’s structure.

• Debris Retention: Rayco’s cutting tool patterns are

designed to minimize the retention of debris in between

the cutting tools. This debris can cause imbalance. This

debris can also become a dangerous projectile. Non-

Rayco cutting tools may retain more debris.

Changing Teeth

Remove the socket head bolts from the teeth. (Use the 1/2”

hex key provided with the machine.)

• Clean all dirt from the cutting wheel and teeth.

• Check the cutting wheel for cracks. Re place the wheel

if it is cracked.

• Carefully select and insert new cutting teeth, properly

positioning each tooth as shown in the diagram on the

next page.

• Bolt the teeth to the cutting wheel (but not tightly until

the pattern has been double-checked).

• After setting each tooth pair, tighten the socket head

bolts to 135 to 145 foot-pounds.

Replacement teeth are available from your Rayco dealer or

direct from Rayco. Refer to the Parts manual for part numbers

BLOCK OR OTHERWISE SECURELY SUPPORT THE

CUTTING BOOM WHEN CHANGING TEETH.

Содержание Super Jr RG27

Страница 47: ...RG27 35 37 Operation Service Maintenance 800 392 2686 47 Maintenance Notes ...

Страница 50: ...RG27 35 37 Operation Service Maintenance 50 Wiring Schematic ...

Страница 51: ...RG27 35 37 Operation Service Maintenance 800 392 2686 51 Wiring Schematic ...

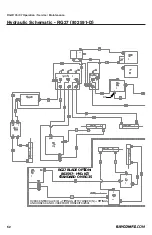

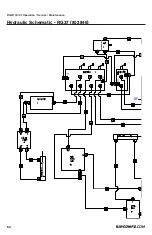

Страница 54: ...RG27 35 37 Operation Service Maintenance 54 Hydraulic Schematic RG37 802846 RF T T P P ...

Страница 56: ...RG27 35 37 Operation Service Maintenance 56 Specifications SERVICING TAPER BUSHINGS ...

Страница 63: ...RG27 35 37 Operation Service Maintenance 800 392 2686 63 ...