RG27/35/37 Operation • Service • Maintenance

800.392.2686

59

Specifications

RAYCO COOLANT SPECIFICATIONS

Coolant / Antifreeze Recommendations

Most commercial antifreezes are formulated for gasoline engine applications and will, therefore, have high silicate content.

These antifreezes are intended for aluminum automotive engines and are unacceptable for diesel engines. Use antifreeze

that is formulated with a low silicate level and the proper coolant additives for heavy duty diesel engines.

Your Rayco machine is filled at the factory with Chevron Heavy Duty Phosphate Free Coolant formulated to meet the heavy-

duty engine coolant specifications of TMC RP329 and ASTM D 6210. This coolant is manufactured from ethylene glycol

and a highly effective, heavy duty corrosion inhibitor package that is phosphate free and contains nitrates and molybdates.

It is compatible with other traditional heavy duty coolants containing supplemental coolant additives (SCA’s).

Rayco’s coolant specification address the following concerns:

• Effective corrosion protection for aluminum, brass, cast iron, steel, solder, and copper.

• Low silicate formulation.

• Protects against winter freeze up and minimizes the chance of summer boil over.

• Phosphate free formula reduces hardwater scale formation.

• Suitable for diesel, gasoline and natural gas powered engines.

• Compatible with other major brands of coolant and heavy duty diesel supplemental additives.

Rayco recommends the following coolant type for your Rayco machine:

Chevron HD Coolant (Phosphate-Free) Concentrate P/N 227036 / 227043 with bitterant …

-34°F @ 50% mx - 62°F @ 60% mix

Chevron HD Coolant (Phosphate-Free) Diluted P/N 227034 / 227045 with bitterant……….

-34°F @ 50% mix -,62°F @ 60% mix

Coolant Maintenance:

• Maintain freeze point between -15°F and -62°F. A 50% mixture has a freeze point of -34°F (refer to freeze point above).

• Use commercially available test strips for both nitrate and molybdate.

• Maintain nitrate levels between 800ppm and 2300ppm.

• Check levels of nitrate and molybdate every 250 hrs.

• Add SCA’s based upon the engine OEM recommendations.

• Top up low coolant systems with a 50% mixture as required.

• Follow the engine OEM procedures when doing a complete change-out.

Make Proper Antifreeze Additions

Adding pure antifreeze as a makeup solution for cooling system top-up is an unacceptable practice. It increases the

concentration of antifreeze in the cooling system which increases the concentration of dissolved solids and undissolved

chemical inhibitors in the cooling system. Add antifreeze mixed with water to the same freeze protection as your cooling system.

Use the chart below to assist in determining the concentration of antifreeze to use.

NOTICE: Additives eventually lose their effectiveness and must be recharged with additional supplement coolant additives

available in the form of liquid coolant conditioner. See TESTING ENGINE COOLANT and REPLENISHING SUPPLEMENT

COOLANT ADDITIVES (SCA’S) BETWEEN COOLANT CHANGES, as described in the Engine Operator’s Manual. For

more detailed explanation on the cooling system refer to the Fuels, Lubricants, and Coolant section of the Engine Operator’s

Manual shipped with this machine.

Chevron HD Coolant Protection Temperature (w/ 15 psi cap) Concentration

Boiling Protection to -129.4°C (265°F)

50% antifreeze and 50% water

Freeze Protection to -24.4°C (-12°F)

40% antifreeze and 60% water

Freeze Protection to -36.7°C (-34°F)

50% antifreeze and 50% water

Freeze Protection to -52.2°C (-62°F)

60% antifreeze and 40% water

Содержание Super Jr RG27

Страница 47: ...RG27 35 37 Operation Service Maintenance 800 392 2686 47 Maintenance Notes ...

Страница 50: ...RG27 35 37 Operation Service Maintenance 50 Wiring Schematic ...

Страница 51: ...RG27 35 37 Operation Service Maintenance 800 392 2686 51 Wiring Schematic ...

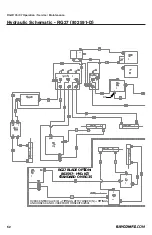

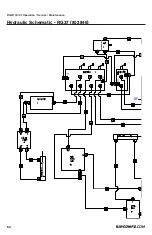

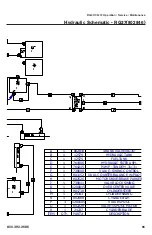

Страница 54: ...RG27 35 37 Operation Service Maintenance 54 Hydraulic Schematic RG37 802846 RF T T P P ...

Страница 56: ...RG27 35 37 Operation Service Maintenance 56 Specifications SERVICING TAPER BUSHINGS ...

Страница 63: ...RG27 35 37 Operation Service Maintenance 800 392 2686 63 ...