RG27/35/37 Operation • Service • Maintenance

800.392.2686

39

Fuel Tank - Fill

The fuel tank (2) is the larger tank behind the battery. Remove

the fuel cap. Carefully fill the tank, and replace the cap. See

“System Fluids Specifications” in this “Maintenance” section

for more information.

Fuel Filter, (In-Line) - Check

Follow the directions found in the Engine Operator Manual.

Engine Fuel Filter - Change

Follow the directions found in the Engine Operator Manual.

Air Filter Indicator - Check

Clean or replace the filter cartridges if the red flag of the

service indicator (3) is fully visible.

Follow the directions found in the Engine Operator Manual.

Air Filter Cartridges - Clean

Clean or replace both the Inner and Outer Filter Cartridges

if the red flag of the service indicator (3) is fully visible.

Replace as needed. Follow the directions found in the Engine

Operator Manual.

Perform this procedure more frequently under extremely

dusty or dirty conditions.

Replace Both Filters

• Check the service indicator (3).

• Unfasten the clamps (4) holding the end cap of the air

cleaner and remove. After replacing the cartridge(s),

replace the end cap of the air cleaner and lock the clamps

so that the dust ejector valve (5) is positioned as shown.

• Replace the inner safety filter cartridge (6) with every

other air filter cartridge replacement.

• Discharge the dust ejector valve (5).

Detailed directions can be found in the Engine Operator

Manual.

Perform this procedure more frequently under

extremely dusty or dirty conditions.

Brake - Test

This machine is required to have a daily inspection of the

ground-drive brake. This check should be done by the operator

every day, before using the machine.

The ground-drive brake on this machine is a spring-activated,

hydraulically-released unit. This means that anytime the unit is

not being moved with hydraulic pressure, the spring-applied

brake should engage. The machine should never visibly

“creep” when it is not being moved.

The machine can be tested on any slope, but the simplest

inspection can be done when unloading or loading the

machine onto its trailer, or into a pickup truck. When the

drive wheels are on the ramps, bring the machine to a halt,

and observe the drive wheels. The wheels should not turn

at all. No “creep” should be evident.

If the machine can be observed to be creeping down the

ramp, check the following items:

• Both drive wheels are engaged.

• Wheel drive chain is properly tensioned with 1/4”

deflection in middle.

• No oil leaks are present in the ground-drive circuit.

Correct all of these items and retest the machine. If the

machine still creeps, then the spring-activated brake has been

damaged. The drive motor must be replaced. Failure to keep

the ground-drive brake in working condition can result in a

machine moving unexpectedly, causing injury or death. The

machine must be taken out of service until the ground-drive

motor is repaired or replaced.

The machine is always to be parked with the drive wheels

engaged, and the drive wheels chocked.

GASOLINE IS HIGHLY COMUSTIBLE. DO NOT

SPILL IT ON THE ENGINE. LET THE ENGINE COOL

BEFORE REFUELING. DO NOT SMOKE OR ALLOW

ANY HOT OBJECTS NEARBY WHEN REFUELING.

3

5

Maintenance

4

6

Содержание Super Jr RG27

Страница 47: ...RG27 35 37 Operation Service Maintenance 800 392 2686 47 Maintenance Notes ...

Страница 50: ...RG27 35 37 Operation Service Maintenance 50 Wiring Schematic ...

Страница 51: ...RG27 35 37 Operation Service Maintenance 800 392 2686 51 Wiring Schematic ...

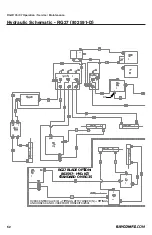

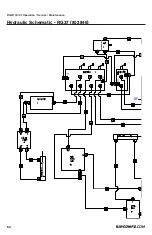

Страница 54: ...RG27 35 37 Operation Service Maintenance 54 Hydraulic Schematic RG37 802846 RF T T P P ...

Страница 56: ...RG27 35 37 Operation Service Maintenance 56 Specifications SERVICING TAPER BUSHINGS ...

Страница 63: ...RG27 35 37 Operation Service Maintenance 800 392 2686 63 ...