RG27/35/37 Operation • Service • Maintenance

42

Maintenance

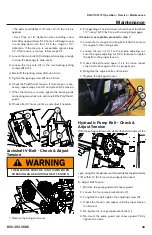

4) Blade Bushings (If Equipped)

Lubricate 3-4 shots of grease into the grease fittings (1).

Note: there should be 4 total fittings.

5) Steering Axle Pivot Knuckles

Lubricate 3-4 shots of grease into the grease fittings (2) on

both steering knuckles.

6) Steering Axle Cylinder

Lubricate 3-4 shots of grease into the grease fittings (3) on

each end of steering cylinder.

7) Self-propel Axle Flange Bearings

Lubricate 3-4 shots of grease into the grease fittings (4) on

both outer axle flange bearings.

Cutting Wheel - Lubricate

Lubricate the two fittings (5) (one on each side) until you

can visually see old grease being purged out of the side

of the bearing.

Cutting Wheel PolyChain® - Check

& Adjust Tension

Using a belt gauge, check the PolyChain® tension by

depressing the PolyChain® at the center of the span.

1. Remove the PolyChain® guard cover. The cutting wheel

must be free to rotate (eg. not resting on ground).

1

1

3

2

2

4

5

THE MACHINE MUST BE SHUT DOWN WHEN

CHECKING AND ADJUSTING BELT TENSION.

Содержание Super Jr RG27

Страница 47: ...RG27 35 37 Operation Service Maintenance 800 392 2686 47 Maintenance Notes ...

Страница 50: ...RG27 35 37 Operation Service Maintenance 50 Wiring Schematic ...

Страница 51: ...RG27 35 37 Operation Service Maintenance 800 392 2686 51 Wiring Schematic ...

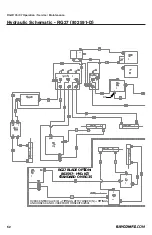

Страница 54: ...RG27 35 37 Operation Service Maintenance 54 Hydraulic Schematic RG37 802846 RF T T P P ...

Страница 56: ...RG27 35 37 Operation Service Maintenance 56 Specifications SERVICING TAPER BUSHINGS ...

Страница 63: ...RG27 35 37 Operation Service Maintenance 800 392 2686 63 ...