27

SERVICING

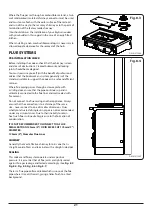

To ensure continued efficient and safe operation of the

appliance, it is recommended that it is checked and serviced

by an Authorised Service Engineer at least once a year.

n

IMPORTANT:-

Flexible oil lines should be inspected at each and every

service visit. It is important in the interest of safety that

flexible lines are changed at regular intervals and should be

changed immediately in all the following cases:

1.

The oil line has been in use in the cooker for 3 years or

more.

2.

The date code on the oil hose shows as five years or

older. (whichever of the above comes first)

3.

The oil hose shows signs of being kinked or damaged,

irrespective of date life service span.

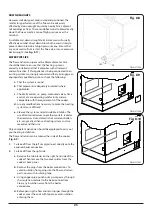

GENERAL MAINTENANCE

It is important that the user is familiar with their heating

system and that they ensure regular checks and maintenance

which can limit unnecessary break-downs.

If in doubt, the user should consult an appropriately qualified

person such as a plumber or heating engineer.

SAFETY VALVE

A non-adjustable 3 bar safety valve must be fitted to the

primary flow pipe adjacent to the boiler connection ensuring

that any discharge will not create a hazard to occupants or

cause damage to electrical components or property.

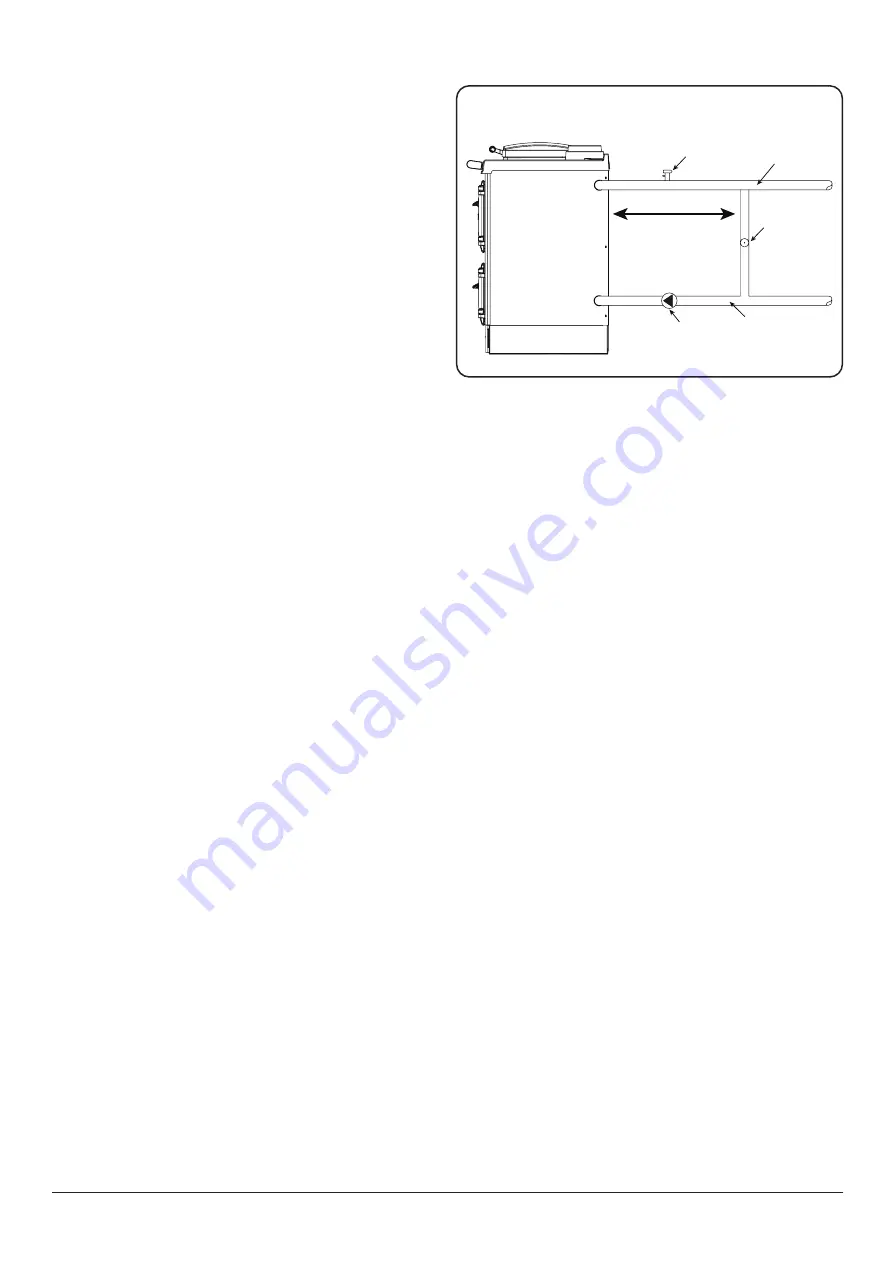

A 15mm system by-pass must be fitted not less than 1.5

meters (4.9ft) from the cooker to allow correct water

circulation for the pump and to prevent condensation

forming in the boiler. This should be balanced. A heat sink

radiator / towel rail may be installed if desired in addition to

the By- Pass Loop. (See

)

NOTE

: We strongly advise the use of pipe lagging and also

the use of a frost thermostat if the installation is likely to be

exposed to situations where the temperature will dip to a

level consistent with frost.

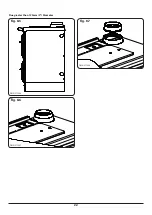

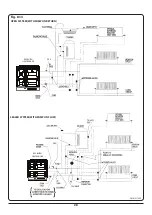

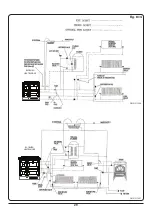

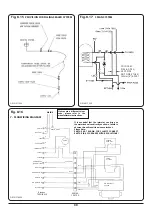

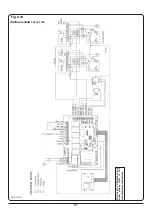

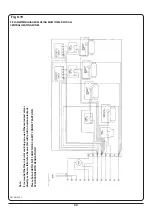

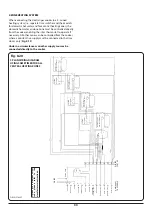

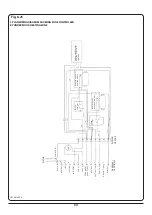

The following diagrams illustrate the different types of central

heating systems to which this appliance can be connected,

but are not to be used as working drawings.

1.5m

By-pass not less than

1.5 meters from the cooker

Safety Valve

28mm Flow

Pipe

By-pass Lock

Shield Valve

28mm Return

Pump

Fig. 8.12

DESN 517994