26

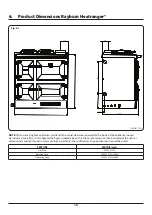

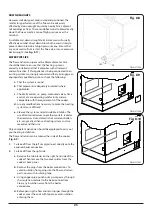

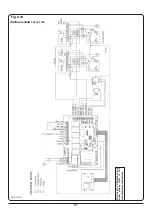

Fig. 8.11

e.

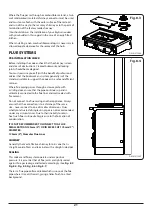

Remove tape from pipes and boiler ports. Connect

pipes to boiler.

f.

Replace blanking plates.

g.

Plug the boiler tappings on the left hand side of the

boiler with 1” BSP plugs.

h.

Test for leaks.

DRAINING

Key-operated drain taps to BS 2879 should be provided in

accessible positions in all low parts of the system. However,

it should be noted that there may be short sections of

pipework, e.g. when passing under doorways, that may not

be possible to drain.

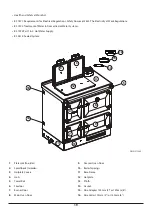

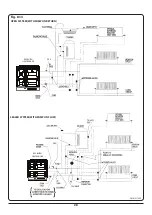

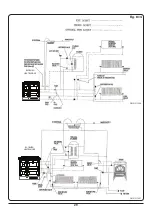

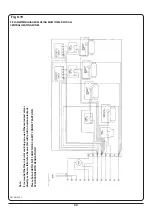

INTERNAL PUMP THERMOSTAT

This appliance has the capability for switching the circulating

pump ‘on’ and ‘off’ automatically. To wire in the pump,

connect the phase to terminal marked CIRC Pump (L) and

connect the Neutral to terminal marked CIRC Pump (N). The

earth wire is to be connected into the earth block.

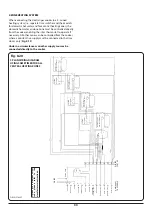

The connection circuit board/control panel is located within

the appliance beneath the warming oven. (See

WATER CIRCUIT TEMPERATURE

The return water temperature should be maintained at not

less than 50°C (122°F) so as to avoid condensation forming

within the boiler.

CARE FOR YOUR CENTRAL HEATING SYSTEM

The use of suitable corrosion inhibitors and anti freeze

solution in your heating system is essential to minimise black

oxide, sludge and scale build-up, which effects efficiency.

In hard water areas the use of a suitable limescale preventer /

remover is advised.

Use only quantities specified by the water treatment product

manufacturer. Only add to the heating system after flushing

and finally refilling. Refer to BS 7953.

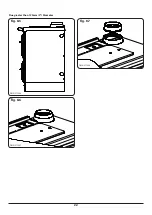

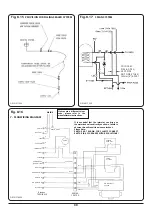

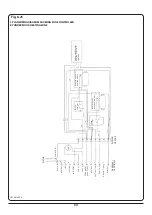

INDIRECT DOMESTIC CYLINDER

The cooker must only be connected to an indirect cylinder

of no less than 180 litres using 28mm diameter flow and

return piping. It is recommended that the cylinder is lagged

together with pipework with runs in excess of 4 meters (12’).

DESN 517993