25

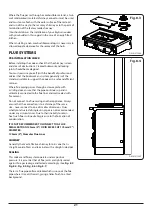

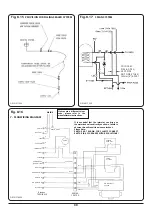

DOWN DRAUGHTS

However well designed, constructed and positioned, the

satisfactory performance of the flue can be adversely

affected by down draught caused by nearby hills, adjacent

tall buildings or trees. These can deflect wind to blow directly

down the flue or create a zone of high pressure over the

terminal.

A suitable anti-down draught terminal or cowl will usually

effectively combat direct down blow but no cowl is likely to

prevent down blow due to high pressure zone. Ensure that

any cowl used will not restrict the flue exit, or cause excessive

back draught. (See

)

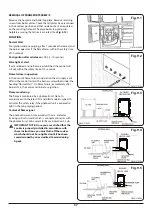

WATER PIPE SIZE

The flow and return pipe must be 28mm diameter. Care

should be taken to ensure that the heating system is

correctly installed and that it complies with all relevant

codes of practice. If this appliance is being connected to an

existing system, we strongly recommend that you engage an

appropriately qualified person to check the following:

a.

That the system is sound.

b.

That pipework is adequately insulated (where

applicable).

c.

Check all controls, i.e. pump, motorised valves, time

control etc. are operating satisfactorily and are

compatible with the requirements of the cooker.

d.

Are any modifications necessary to make the heating

system more efficient?

e.

Cleanse the system and add suitable inhibitor. The

use of motorised valves, room thermostats, radiator

thermostatic valves, domestic hot water controllers,

etc, can greatly enhance a heating system and we

recommend their use.

Only competent personnel should be employed to carry out

your heating installation.

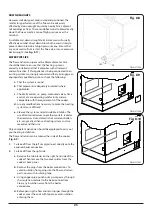

The flow and return can be taken either side of the cooker

1.

To take off from the left simply connect directly onto the

exposed boiler connection.

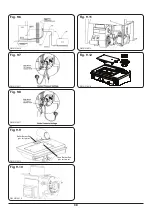

2.

To take off from the right side:

a.

Remove the two blanks on the right hand side of the

cooker. Then remove the two cover plates from the

cooker’s back panel.

b.

Remove the plugs from the boiler connections. To

avoid insulation from going into the flow and return

ports, cover with insulating tape.

c.

Using copper pipe, punch out a passage way through

the insulation material to the boiler connections.

Clear any insulation away from the boiler

connections.

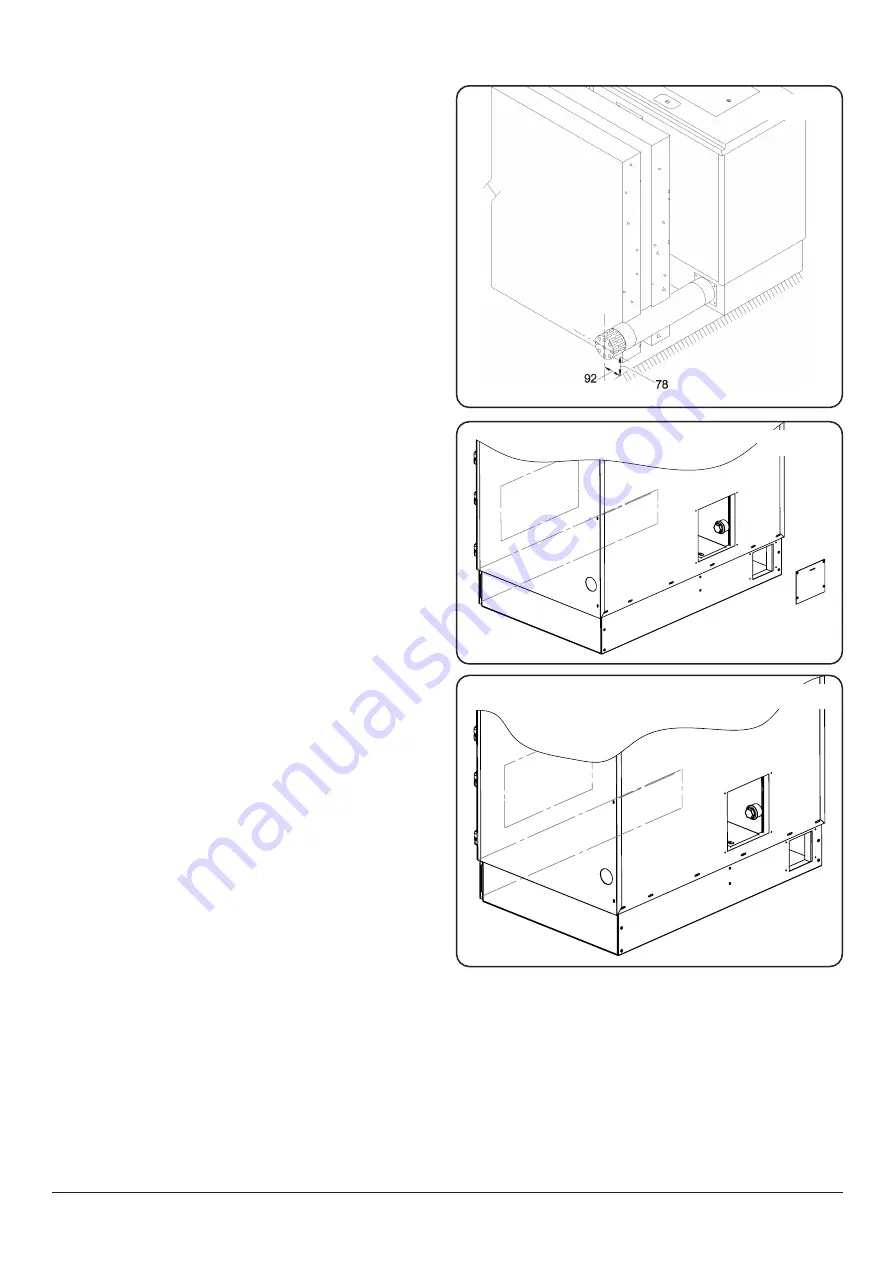

d.

Before passing the flow and return pipes through the

cooker, cover the ends with tape to avoid insulation

entering them.

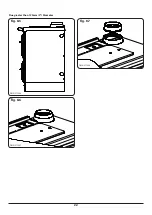

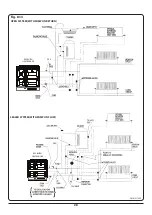

Fig. 8.8

Fig. 8.9

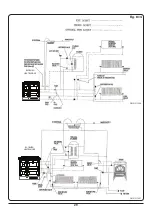

Fig. 8.10

DESN 517992

DESN 517990

DESN 517991