24

FACTORY MADE INSULATED CHIMNEYS

Factory-made insulated chimneys should be constructed and

tested to meet the relevant standards and recommendations

given in:

•

B.S. 7566 - Installation of factory-made chimneys

conforming to B.S. 4543 for domestic appliances.

•

Part 1: Method of specifying installations design

information.

•

Part 2: Specification for installation design.

•

Part 3: Specification for site installation.

•

Part 4: Recommendation for installation design and

installation.

VENTILATION & COMBUSTION AIR REQUIREMENTS

1.

It is imperative that there is sufficient air supply to

the burners of the cooker in order to support correct

combustion.

2.

The air supply to this appliance must comply with BS

5410 Part 1.

3.

The minimum effective air requirement for this

appliance is 215 cm2 (100), 193 cm2 (80) or 155cm2

(60). When calculating combustion air requirements

for this appliance use the following equation: 550mm2

per kW of maximum rated output above 5kW. These

requirements are illustrated in OFTEC Technical Book

No. 3 & B.S. 5410.

4.

If there is another appliance using air fitted in the same

or adjacent room, it will be necessary to refer to B.S.

5410 to calculate the additional air supply.

5.

All materials used in the manufacture of air vents

should be such that the vent is dimensionally stable and

corrosion resistant.

6.

Air vents direct to the outside of the building should

be located so that any air current produced will not

pass through normally occupied areas of the room.

An air vent outside the building should not be located

less than the dimensions specified within the Building

Regulations (See Technical Data) from any part of any

flue terminal. These air vents must also be satisfactorily

fire proofed as per Building Regulations.

7.

Air vents in internal walls should not communicate

with bedrooms, bedsits, toilets, bathrooms or rooms

containing a shower.

8.

Air vents traversing cavity walls should include a

continuous duct across the cavity. The duct should be

installed in such a manner as not to impair the weather

resistance of the cavity.

9.

Joints between air vents and outside walls should be

sealed to prevent the ingress of moisture. Existing air

vents should be of the correct size and unobstructed for

the appliance in use.

10.

If there is an air extraction fan fitted in the room or

adjacent rooms where this appliance is fitted, additional

air vents will be required to aleviate the possibility of

spillage of combustion products from the appliance/

flue while the fan is in operation. (Refer B.S. 5410).

11.

Where such an installation exists, a test for spillage

should be made with the fan or fans and other burning

appliances in operation at full rate (i.e. extraction fans,

tumble dryers) with all external doors and windows

closed.

12.

If spillage occurs following the above operation, an

additional air vent of sufficient size to prevent this

occurrence should be installed.

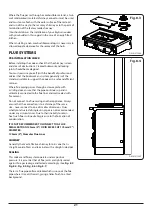

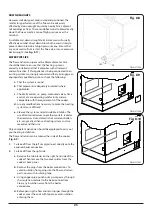

OUTSIDE AIR CONNECTION

If this option is used additional air as indicated in BS 5410 is

not required.

1.

This appliance may be connected direct to the outside

of the house for its combustion air supply.

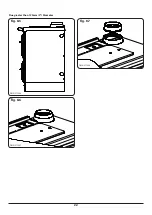

2.

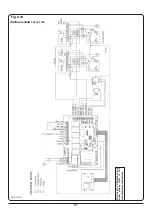

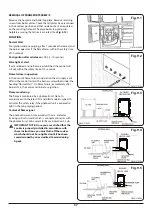

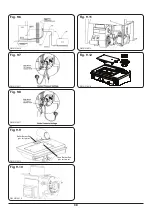

Remove the blanking plate located at the back right

hand corner and remove the primary air grill located at

the front right hand corner. Fix the blanking plate over

the front primary air inlet. (See

3.

Connect the optional 125mm (5”) spigot to the base.

(See

).

4.

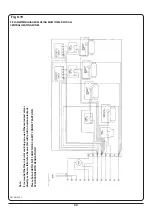

To connect this appliance to an outside air supply use

either 125mm (5”) rigid or flexible stainless steel pipes

or non-combustible corrosion-resistant materials not

more than 965mm (38”) in length and having no sharp

bends or corners other than the down turn at the

terminus.

5.

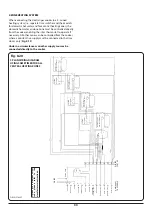

Air inlets traversing cavity walls should include a

continuous duct across the cavity. The duct should be

installed in such a manner as not to impair the weather

resistance of the cavity.

6.

Joints between air vents and outside walls should be

sealed to prevent ingress of moisture.

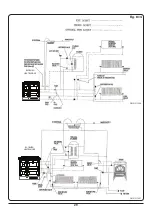

HEATING

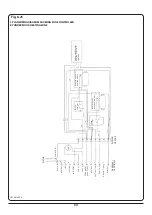

PIPE FITTINGS

Materials used for insulation work should be fire resistant.

Standards should conform to all appropriate regulations in

force at the time and place of installation.

1.1

Ferrous Materials

BS 1387 Steel tubes.

BS 1740 Steel pipe fittings.

BS 4127 Stainless steel tubes.

BS 6956 Jointing Materials.

2.2

Non-Ferrous Materials

EN 29453 Soft Solder Alloys.

BS 864 Compression tube fittings.

BS 2871 & BS EN 1057 Copper & Copper

Alloys.