Supplied By www.heating spares.co Tel. 0161 620 6677

6

SECTION 1

INTRODUCTION

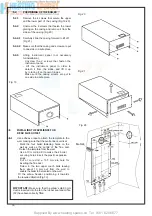

1.1

The CSI Primary is a gas fi red room sealed

fan assisted condensing heating boiler suit-

able for fully pumped open vented or sealed

system central heating and domestic hot

water systems.

1.2

The provision of stored domestic hot

water

is

possible by the addition of

an indirect cylinder with ‘Y’ or ‘S’ plan

controls

The

data badge is placed on the

front

panel.

1.2.1

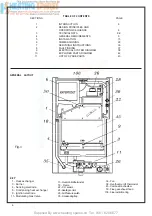

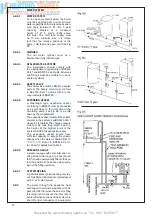

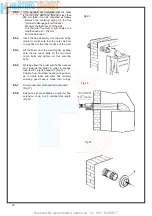

Fig 1 illustrates the general layout of

components.

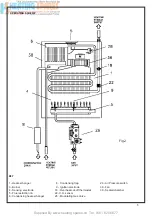

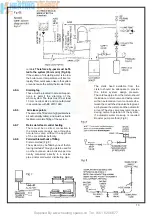

Fig.2 illustrates the operating principals

described in section 2.

SECTION 2

DESCRIPTION OF CONTROL SYSTEM

AND SEQUENCE OF OPERATION

2.1

If the main neon is on with a demand for

heat to the system (radiators etc ) the fan

operates via the pressure switch and sends a

signal back to the ignition board that the fan

is running at maximum speed.

2.2

The spark ignition system is powered which

in turn commences the spark ignitor to

operate and light the burner. At this point

the ignition board opens the gas valve to light

the burner.

2.2.1

When the electrode/sensor senses the sig nal

of the burner the spark ignition stops.

2.2.2

From the minimum gas rate setting

the boiler increases to the maximum

permissible pressure over a period

of 3 to 4 seconds and will remain at

its maximum required power until its

maximum regulated temperature.

2.2.3

When the boiler thermostat is satisfi ed the

boiler will go to rest mode, the burner is shut

down and the pressure switch will return

back to its rest mode.

2.2.4

As the heating sensor reaches temperature

the gas burner power modulates down,

the fan speed. When starting, the fan will

always start at maximum speed.

2.2.5

The boiler is fitted with an anti-cycling

device on the control board. This delays

the boiler from re-firing over a 2/5 minute

period.

2.3 GENERAL

FUNCTION

2.3.1

The gas valve boiler output settings may

be adjusted to requirements other than

factory settings

2.3.2

Air is drawn by the fan for combustion

2.3.3

he fan also forces exhaust gas through the fl ue

to the outside, this creates a lesser pressure

in the sealed combustion cham

ber, thus

sucking in combustion air through the inlet duct

2.3.4

The boiler water temperature is automati

cally

controlled by a built in thermostat

2.3.5

Interior space temperature is set by the room

thermostat to be installed in the heat ing system The

boiler already carries con nection terminals for this

thermostat, as well as for a timeclock The burner

contin ues to operate until it is stopped by the

timer or one of the thermostats

2.3.6

When the room thermostats and/or timer intervene

the burner shuts down The fan stops and the pump

off via the pump overrun.

2.3.7

The condensate trap is fi tted with a block age safety

sensor This prevents the boiler operating should there

be a blockage in the condensate discharge trap.

2.3.8

An overheat cut off thermostat set slightly higher

than the heat thermostat acts to turn off the burner to

resetable “lockout” (Fig 50) .

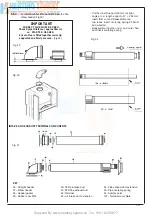

SECTION 4

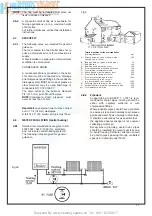

GENERAL REQUIREMENTS

4.0

SAFETY

Gas Safety (Installation and Use)

Regulations, 1994 and amended 2000.

It is law that all gas appliances are installed

and serviced by a CORGI registered installer in

accordance with the above regulations and these

installation instructions. All CORGI registered

installers carry a CORGI I.D. card and have a

registration number. Both should be recorded in

your boiler log book. You can check your installer

by calling CORGI direct on: 01256 732300.

Failure to install appliances correctly could lead to

prosecution. It is in your own interest, and that of

safety, to ensure the law is complied with. Check

the boiler and flue is the correct type for installation.

The installation of the boiler MUST be in

accordance with the latest I.E.E. (BS 7671) Wiring

Regulations, local building regulations, bye-laws

of the local water authority, the building regulations

and the Building Standards (Scotland) and any

relevant requirements of the local authority.

authority, the building regulations and the Building

standards (Scotland) and any rele vant requirements

of the local authority.

4.1

GENERAL INFORMATION

Both the user and the manufacturer rely

heavily on the installer, whose job it is to in

stall the

combination boiler and connect it to a correctly

designed heating system Ac

quaint yourself

with the British Standards concerning installation

requirements If you need advice on any points

your Ravenheat Technical Services Offi ce would be

pleased to help It is recommended that tools suitable

Содержание HE Primary AAA

Страница 16: ...Supplied By www heating spares co Tel 0161 620 6677 17 Fig 18...

Страница 31: ...Supplied By www heating spares co Tel 0161 620 6677 Fig 58 32 Fig 56 Fig 57...

Страница 33: ...Supplied By www heating spares co Tel 0161 620 6677 34 Fig 60 Fig 61 Fig 62 Fig 63...

Страница 36: ...Supplied By www heating spares co Tel 0161 620 6677 Section 9 ELECTRICAL SYSTEM DIAGRAM Fig 94 37...

Страница 42: ...Supplied By www heating spares co Tel 0161 620 6677 section 10 EXPLODED PARTS DIAGRAM 43...