Supplied By www.heating spares.co Tel. 0161 620 6677

21

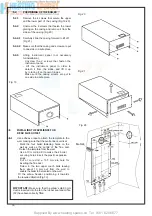

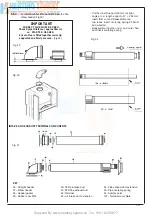

5.5.9

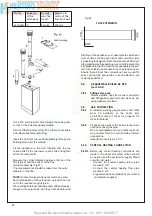

Each extension length extends the pipe by

approximately 1000 mm long up to a maxi mum

of two extensions.

Pipeline length can be established using the

instructions in section 5.5 for rear fl ue outlets

and section 5.7 for side fl ue outlets. Extensions

must be installed with the widened end of the air

intake pipe and the tapered end of the fl ue pipe

aimed towards the exhaust terminal. Extensions

must be joined together with the standard

terminal pipe, and inserted in each other as far

as they can go.

If an extension must be shortened, this must

be done from the straight end, and not from the

widened or tapered end .To mea sure the pipeline

properly all components must be assembled

and total length mea sured before cutting. The

straight end of the extension connects to the

boiler. The fl ue output pipe fi ts into the boiler

header until it stops .The air intake pipe should

be located approximately 2 mm from the boiler

header (Fig 31).

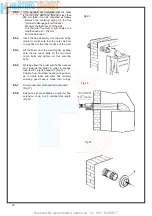

When cutting both inner and outer ducts of the

extension, always ensure that the reduced end

(male) of the inner duct is longer than the outer

duct.

All joints must be sealed with the rubber seals

supplied.

It is important to put the centering spacer,

supplied with the unit, inside between the two

pipes, from the side opposite the exten

sion’s

straight end.

NOTE:

A

suitable support bracket is availa ble

from Ravenheat Manufacturing and should

be used to support fl ue length at least every

1.8 metre preferably at each joint this bracket

should be secured to wall and fl ue duct.

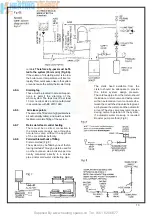

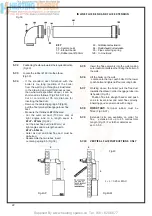

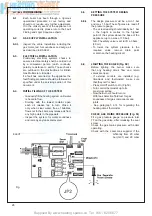

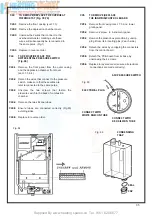

5.5.10

INLINE FLUE BEND

Measure the distance between the fl ue bends or

the fl ue/terminal assembly. The measurements

should be taken from the outer edge of the fl ue

and bend(Fig.39).

IMPORTANT:

Inline fl ue

bend - 1680 mm must be deducted from

overall length for each 90° bend - 1680 mm

must be deducted from overall length for

each 135° bend (Fig 39).

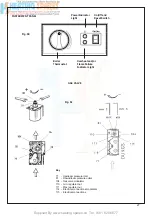

5.6

COMPLETING BOILER INSTALLATION

5.6.1

Reassemble the outer casing (sect 5 4)

proceeding in this order

1) Fit the two sides

2) Refi t the instrument panel in reverse ord er

as in sect. 5.4.3.

3) Refi t the lower grating .

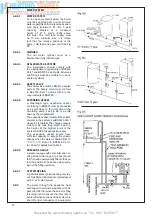

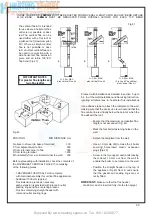

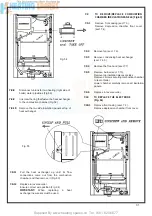

5.7.1

- Attach the template to the wall with adhe-

sive tape, making sure that the centre line

is vertical and that the distance from the

centre line to the nearest side wall is not

less than measurement in table 6.

- Mark the four boiler securing holes on the

wall and extend the axis of the fl ue duct

hole to the side wall ensuring it is

horizontal.

- Trace the centre of the fl ue duct hole

measure distance F (table 6) From the

corner of the wall (Fig. 28), measure the

distance Y between the centre of fl ue duct

hole to the corner Detach the template

from

wall.

- Use a dia 10 mm drill to make the 4 holes

for securing the boiler Insert the plastic

expansion plugs Core drill a 105 mm dia

hole in the side wall for inserting the fl ue

duct.

TABLE

6

CSI PRIMARY

F = 140 mm

G = 275 mm

5.7

INSTALLING THE APPLIANCE FOR SIDE

FLUE OUTLET (Fig. 28)

Содержание HE Primary AAA

Страница 16: ...Supplied By www heating spares co Tel 0161 620 6677 17 Fig 18...

Страница 31: ...Supplied By www heating spares co Tel 0161 620 6677 Fig 58 32 Fig 56 Fig 57...

Страница 33: ...Supplied By www heating spares co Tel 0161 620 6677 34 Fig 60 Fig 61 Fig 62 Fig 63...

Страница 36: ...Supplied By www heating spares co Tel 0161 620 6677 Section 9 ELECTRICAL SYSTEM DIAGRAM Fig 94 37...

Страница 42: ...Supplied By www heating spares co Tel 0161 620 6677 section 10 EXPLODED PARTS DIAGRAM 43...