Page 8 of 8

TRIGANO MDC - Haut-Eclair – 72600 MAMERS

9.

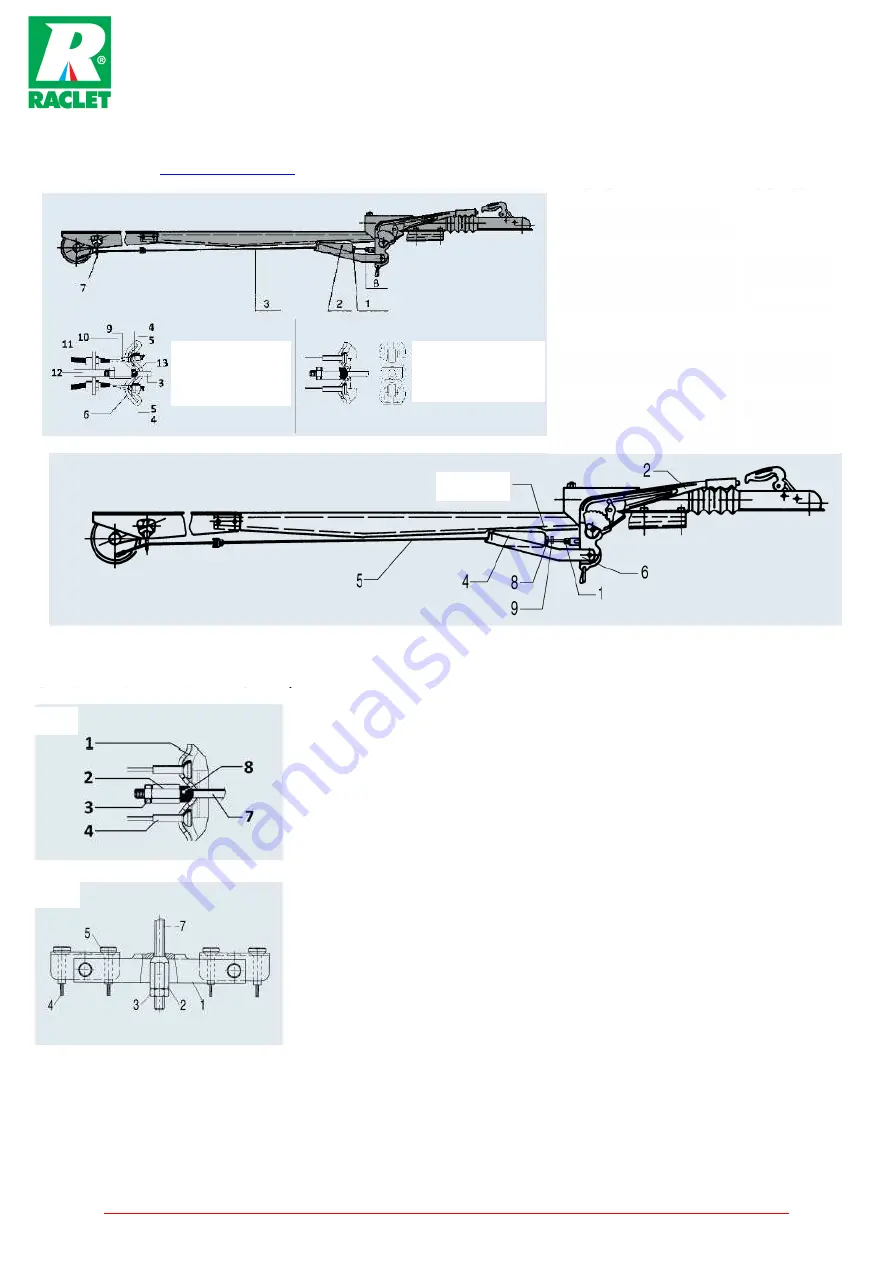

Appendix 1: Adjusting the inertia brake with a compensator

Source:

www.alko-tech.com

- General catalogue.

Assembly with

threaded

connectors

Brakes 3062/3081.

Quick set-up Brakes

1636 G / 1637 / 2051 /

2361

Washer

1. Assemble the inertia brake

control and axle on the chassis.

2. Assemble the brake cable

connectors on the crosspiece.

3. Thread the rod rep.5/fig.1

through the central hole in the

crosspiece rep.1/fig.4 or 5, the

return plate rep.6/fig.1 attached to

the handbrake lever and the

compensator rep.4/fig.1. Screw 3 x

M10 nuts + 1 washer onto the rod

connector (one nut positions the

compensator and another is the

lock-nut. The third is the lock-nut

on the thread side of the brake

control). Position the screw nut

and lock nut at least 5mm from the

compensator.

4. Screw the end of the rod into the

thread (lower part) of the brake

control and tighten the lock-nut.

5. The other end of the rod rep.

5/fig.1 is threaded through the

central hole in the crosspiece.

Insert the strut rep. 8/Fig.4 then

screw the long nut rep. 2/Fig.4 or

spherical nut M10 rep. 2/Fig.5 onto

the crosspiece until there is no

more play in the transmission

system. Check the wheels turn

freely when going forwards.

6. Thoroughly manipulate the

brake lever three or four times and

put it into the down position (pull it

towards the front of the coupling

head or ring). Check the sliding

mechanism is fully extended.

7. At the crosspiece rep.1/fig.4 or

5, screw on the long nut rep.

2/Fig.4 or spherical nut M10 rep.

2/Fig.5 by simultaneously turning

the left and right wheels forwards,

until you obtain significant

resistance that feels equal on both

wheels (tightening limit).

Description

Product code

1. Nut MI0 Din 934.8

705 378

2. Compensator

207 502 06 01

3. Rod

See page 85

4. Olive

207 485 05 03

5. Nut M10 Din 934.8

700 109

6.

Single

crosspiece

-

Brake

1637/2051/2361

165 14 19

Single crosspiece - Brake 3062/3081

165 28 43

For tandem axle, dual crosspiece 238 576 assembled)

7. Welded fulcrum for single axle 208

208 193 01 03

Welded fulcrum for tandem axle

208 889 00 03

8. Nut M10 or M12 Din 934.8

705 378 or 705 379

9. Cable

See pages 168-169

10. Long nut - Brake 1637/2051 /2361

706 154

Long nut - Brake 3062/3081

706 281

11. Nut M10 or M12 Din 934.8

705 378 or 705 379

12. Rod holder

228 827

13. Strut - Brake 1637/2051/2361

165 14 90

Strut - Brake 3062/3081

165 42 83

8. Once you have completed this,

unscrew the long nut rep. 2/Fig.4

or spherical nut M10 rep. 2/Fig.5

two or three turns (use a point of

reference). Tighten the nut rep.

3/Fig.4 or 5. Check the wheels turn

freely (a slight rubbing noise is

normal).

9. Press the compensator against

the return plate and screw on the

nut rep. 8/Fig. 1 until you obtain

max. play (J) of 1mm between nut

rep. 8/Fig.1 and the compensator.

Tighten the lock-nut rep. 9/Fig.1.

Cables with spherical connectors

Fig 4

Fig 5