Biasi SG Pro Series

Page 23

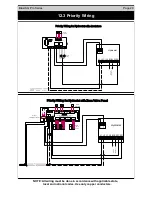

The electricity to the boiler shall come from a dedicated breaker in the electric

service box. A service switch should be mounted on the side of the boiler so the burner

technician can service the burner and controls. The electrical wiring should be routed so as not

to interfere with normal servicing of the boiler. Wiring done in the field between devices not

attached to boiler shall conform with the temperature limitations for type T wire (63F/35C) or

other specified wire as applicable when installed in accordance to manufacturer's

instructions and wiring diagrams.

If an external electrical source is utilized, the boiler, when installed, must be electrically

bonded to ground in accordance with the requirements of the authority having jurisdiction or, in

the absence of such requirements, with the National Electrical Code, ANSI/NFPA 70 and/or the

Canadian Electrical Code Part 1, CSA C22.1, Electrical Code.

Wiring the boiler

Power for the SG Pro series boiler

should be brought to the junction box in the

back of the boiler under the top panel

(Figure 12.1). Line voltage from the fire-o-

matic should be applied to the black wire.

The neutral leg should be connected to the

white wire and the ground to the green

wire. If a external circulator will be

controlled by the Hydrolevel control, use

the red wire in the junction box to power the

circulator. The dry contact switch for the

Hydrolevel low voltage control circuit (TT)

should be connected to the terminals on the

right rear of the boiler (Figure 12.2).

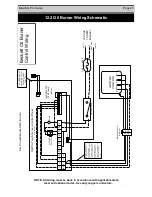

Direct Vent Applications

On applications with Direct Vent Burners a

field installed jumper

is required from terminal #3 to

terminal #7. The capped off black wire also needs to be terminated to #7. This provides a fused

constant 120volt power supply for the post purge of the burner.

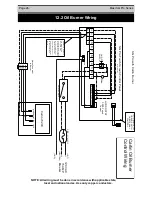

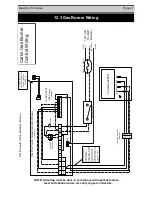

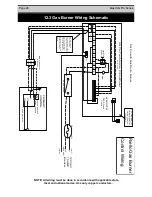

Refer to pages 26 to 28 for oil wiring diagrams and page 29 for gas

wiring diagrams.

12.1 Wiring

Figure 12.1

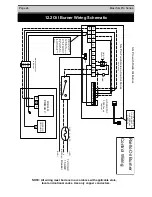

Figure 12.2

Содержание SG-3

Страница 2: ...Page 2 Biasi SG Pro Series...

Страница 33: ...Biasi SG Pro Series Page 33 Notes...

Страница 34: ...Page 34 Biasi SG Pro Series Notes...

Страница 35: ...Biasi SG Pro Series Page 35 Notes...