16

POCKET ANCHORAGE INSTALLATION

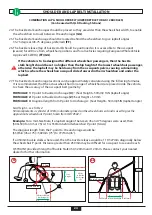

Oval L-Pocket (Part # Q5-7571-A)

1. Use Pocket as template to mark centre of hole to be

drilled

2. Remove pocket and drill 3/8” (10mm) hole through

floor

3. Clean out debris and pass 3/8” (10mm) bolt through

pocket, vehicle floor, Backing plate and Washer. (G)

4. Sealant may be used between Backing plate and floor

is desired

5. Securely fasten bolt and lock nut ensuring at least 2-3

threads are sticking out.

Recommended torque = 35 FT/LB (47 N.m.)

WOOD FLOOR

BOLT

OVAL ‘L’

VEHICLE FLOOR

BACKING

PLATE

WALNUT

WASHER

BOLTS

COVERED FLOOR

WOOD FLOOR

BACKING PLATE

LOCK NUTS

VEHICLE FLOOR

Covered L-Pocket (Part # Q5-7570-A)

1. Route an area in the floor for each pocket 5.0”

(127mm) long x 1.4” (36mm) wide x 0.4” (10mm)

deep

2. Insert Pocket and use as template to mark centre of

two (2) holes to be drilled (H )

3. Remove pocket and drill two 5/16” (8mm) holes

through floor

4. Clean out debris and place sealant in floor opening.

Reinstall pocket.

5. Pass 5/16” (8mm) bolt through pocket, vehicle floor,

Backing plate and Washer.

6. Sealant may be used between Backing plate and

floor is desired

7. Securely fasten bolt and lock nut ensuring at least

2-3 threads are sticking out.

Recommended Torque=25 FT/LB (34 N.m)

• Pocket may be used with all Q’straint tiedowns EXCEPT QRT3 or QRT5 series retractors.

• Pockets MUST be installed in-line (parallel) to the wheelchair space.

•

If not using Q’Straint hardware, only use minimum Grade 8 bolts (reference ASTM 574 bolt specification) coated in

adequate protection against corrosion per ISO 7253 or ASTM B117

G

H

IMPORTANT

Determine location of Anchorages, refer to

Figure 1 & 2