12

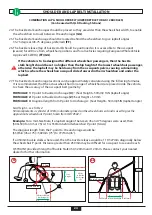

FLOOR ANCHORAGE LAYOUT REQUIREMENTS

o

Safety eye glasses MUST be worn whenever installing or servicing this system.

o

Before installation, inspect the underside of vehicle floor, note utilities, frames, cross-members, fuel tanks and other

possible obstructions—any questions contact the vehicle OEM.

o

Vehicle anchor points may require reinforcement. The installer or manufacturer is responsible for ensuring

anchorages are installed into suitable floor structures. Floor strength MUST meet specific regulations, standards and

applicable performance requirements from local transportation authorities.

o

Do NOT install anchorages or any system components into faulty materials such as corroded metal, wood, plastic or

fiberglass panels.

o

The floor and shoulder belt anchorages MUST be installed onto a flat and durable surface.

o

Only use Hardware with a minimum Grade 8, which meets ASTM F835 ,SAE J429 or ASTM 574 specifications

(depending on head style and drive), and coated for adequate protection against corrosion per ISO 7253 or ASTM B117

or per customer requirements.

o

Modifications to Backing Plate MUST only be made where necessary as a smaller plate size reduces the floor load

distribution. Always leave a minimum of .6” (15mm) adjacent the bolt hole in the plate.

o

Electrical Retractors are designed and tested to ONLY be used in the front positions together with Q’Straint® 4-Point

Securement Systems.

o

Electrical Retractors MUST be mounted in a horizontal plane so that the webbing does not jam or at a 30 degree angle

using Q’Straint Bracket (part # Q8-6510).

o

The following items should be inspected and serviced by an experienced and trained technician during the scheduled

maintenance:

o

Clean all debris from floor anchorages.

o

Verify that floor anchorages are not damaged or corroded.

o

Verify that all mounting bolts are tight.

o

Inspect entire system to make sure everything is working properly and replace anything that is needed.

o

Rigid components inside the clear zones (2a & 2b) should be covered with padding that conforms to the impact

requirements of FMVSS 201 or ECE R21

o

Additional vehicle interior padding should have a burning rate that does not exceed 100mm/min when tested in

accordance with ISO 3795