Visit www.princessauto.com for more information

11

Twin Tank Wheelbarrow Portable Air Compressor

8474488

V 3.03

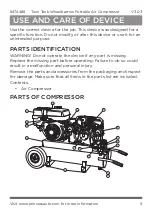

6. Pilot-Unloader Valve

A pilot-unloader valve is used on all gas-powered units.

When the storage tank reaches the top pressure setting of

the pilot valve, the air being compressed is discharged to

atmosphere instead of into the storage tank. When the tank

pressure drops to the low pressure setting of the pilot valve,

the compressed air will be redirected to the air tank. Do not

attempt to replace the pilot valve without first draining the

tank pressure completely. See Pilot Valve Adjustment for

adjustment and fine-tuning instructions. Do not adjust above

the following factory recommendations.

7. Sight Gauge

Prior to daily operation, make a habit of checking the oil

level of the compressor pump and engine. Our belt-driven air

compressors are equipped with a sight gauge to make the

daily task of checking the oil level easier. Always maintain the

oil level to read 2/3 full on the sight gauge.

8. Check Valve

The air compressor is built with a check valve to seal off and

maintain tank pressure after the top end pressure setting of

pilot valve or pressure switch is reached. The check valve

works in conjunction with the pressure switch relief valve to

provide a loadless start for the compressor system. A quick

burst of air escaping from the pressure switch relief valve

after an electric unit reaches top end indicates the check

valve is working properly. If the compressor has a mysterious

leak after stopping that cannot be traced elsewhere, the

check valve may require servicing/replacing.

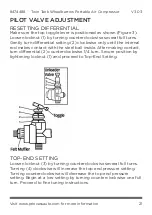

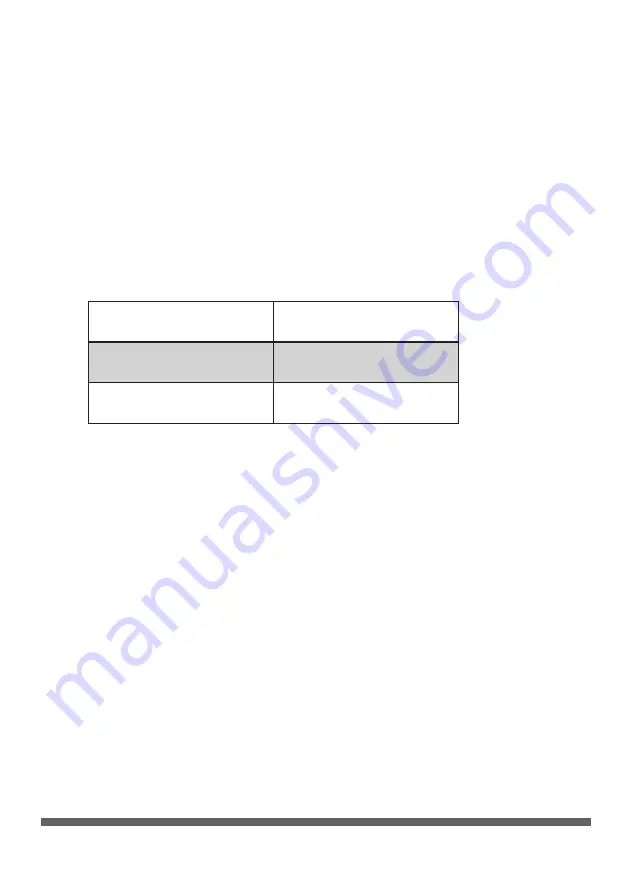

Classification

Pressure Setting

I-Stage Compressor

110 to 135 PSI

II-Stage Compressor

130 to 150 PSI