10

For technical questions call 1-800-665-8685

Twin Tank Wheelbarrow Portable Air Compressor

V 3.03

8474488

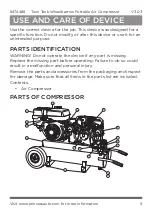

1. Safety-Relief Valve

The air compressor is equipped with a safety-relief valve that

is designed to discharge tank pressure at a predetermined

pressure setting. Check the pressure relief valve periodically

by pulling on the ring only when the tank pressure is

completely drained.

The spring loaded valve should move freely within the

pressure relief valve body. An inoperable pressure relief valve

could allow an excessive amount of tank pressure to build,

causing the air tank to catastrophically rupture or explode.

Do not tamper with or attempt to eliminate the safety

relief valve.

2. Regulator – Working Pressure

To adjust the output/line pressure, simply lift up on the

regulator adjustment knob and rotate clockwise to increase

working pressure or counterclockwise to decrease. Push

adjustment knob back down to lock in setting. Never exceed

the manufacturer’s maximum allowable pressure rating of the

tool being used or item being inflated.

3. Pressure Gauge(s)

Gauges to measure tank or storage pressure and another

gauge attached to the regulator that indicates output or

working pressure.

4. Drain Valves

One or more drain valves are installed to allow moisture to be

drained on a daily basis from the compressor storage tanks.

Open drains carefully and slowly to prevent scale, rust or

debris from becoming expelled at a high rate of speed. Keep

drain valves open when not in use.

5. Air Intake Filter

Air intake filters are installed to prevent foreign matter from

entering the engine or compressor pump. Check intake

elements on a regular basis and either clean or replace as

needed. Warm soapy water or low compressed air may

be used to clean the elements. Check intake canisters or

elbow components for cracks or broken seals and replace if

structural problems are found.