Pronk Technologies

2017 07-18

www.pronktech.com

800-541-9802

Page 19

©2015

e)

When closing the TWedge program for the first time, you will be prompted to save the changes you

made. This refers specifically to the com port assignment you changed. Click /select yes to save the

changes.

f)

The next time you launch TWedge on that PC it will use the same script file with the correct com port

assignment without any further modifications. You will only need to click on START within TWedge

to begin communications with FlowTrax assuming it’s primed, connected and powered on.

NOTE:

Ensure you Reset (F3) to clear prior data before data capturing.

18)

Flow Tr ax

Serial Port Protocol

Overview: The FlowTrax with software version 1.5 or higher comes standard with a serial (RS-232) communication

interface. This feature enables the FlowTrax to send results to a customer’ supplied interface as well as

commercially available programs like HyperTerminal. FlowTrax Serial Port can be easily adapted for computers

with USB ports by using a Serial to USB converter. Test results that can be captured from FlowTrax via the Serial

interface include Flow Rate, Volume, Pressure, Maximum Pressure, elapsed time and temperature. FlowTrax can

also be controlled by the customer’ supplied interface.

RS-232 Pin Assignments (chart/diagram at end of this section)

•

DB-9 Female: Pin 2=Rx, Pin 3=Tx, Pin 5=Gnd.

•

Stereo Jack: The Serial connector at 2.5mm Stereo Jack wired: Tip=Rx on DB-9, Base=Ground, Ring=Tx on

DB-9.

Configuring communications: Baud rate is 57600, 1 start, 1 stop, no parity, no handshake.

Important Notes before starting RS-232 communications:

1.

All polls or commands going to the FlowTrax must have at least 2ms spacing between them as the

FlowTrax cannot receive back to back data at 57600 without losing data.

2.

Use the Device ID report to verify the connection to the FlowTrax. (“I” upper case i)

3.

Turn off Diagnostic mode when first establishing communications. (“g”, then “l”

lower case L)

4.

Prime status can be checked using serial, by polling the volume (“v”)

5.

Run fluid into the FlowTrax until it primes. Then stop the flow and issue a Reset Reading command (“R”).

Recheck prime status after the Reset Reading is complete.

6.

Use the Zero Pressure command to zero the pressure transducer. This should always be done with the input

Lure fitting disconnected. (“Z”)

7.

Pressure polling is available in PSI or mmHg. Pressure Curve data is always in PSI.

8.

When connecting the stereo jack, Pressure units can sometimes change on the display.

9.

Some FlowTrax keys may not function during serial communications.

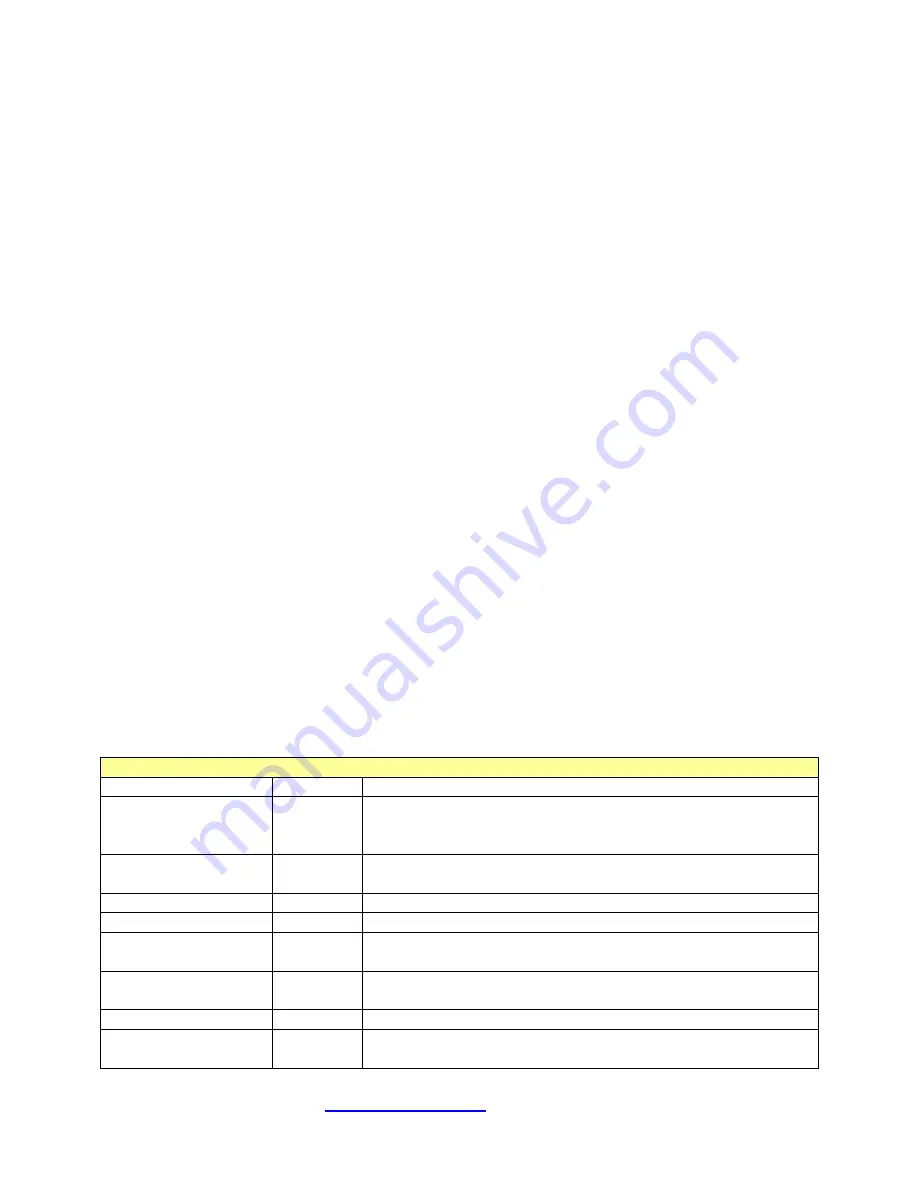

Commands and Reports for all Modes

Function

Command Detailed Description

Reset Reading

‘R’

Resets the bubble tracker and the flow meter (volume, rate and

rate history cleared), Resets the trend data, stops and clears the

stopwatch, stops and clears the trend timer. 1.0 and above.

Device ID Report

‘I’

1.4 and below: returns “FlowTrax”

future version: ‘FlowTrax SN XXX’

Poll Software Version

‘V’

Returns software version, e.g.: “SW: 1.4.0C2”

Enter Flush Mode

‘F’

Enters flow thru mode. Use ‘R’ to exit.

Enter Clean Glass

Mode

‘A’

Fills glass with air. Use ‘R’ to exit.

Zero Pressure

Command

‘Z’

Zeros pressure transducer offset and Max Press

Zero Max Pressure

‘z’

Zeros Maximum Pressure

Poll Tube Calibration

and settings

‘C’

Returns tube cal, and settings: bubble size, front optical, rear

optical, e.g.: “C,1290,84,50,49”