19

Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

Reassemble by first making wire

connections per Figure 4. Attach ground

wire (30) to cover plate (5) with screw (26)

and washer (27). Apply thread locking

compound to cap screws (19), and

along with washers (20) and cover plate,

assemble to motor housing (1). Torque

to 16 ft lbs. Tighten cable connectors

(32) and (36) to 15 ft lbs to prevent water

leakage.

Wiring Connections -

Check power cable

(29) and control cable (34) for cracks or

damage and replace if damaged. Bring

motor wires through opening in top of

motor housing (1) and reconnect motor

leads to power cable and sensor leads to

control cable using connectors (31) and

(33) per Figure 4.

IMPORTANT! - WIRE COLORS MAY

VARY. USE IDENTIFICATION TAG

ON EACH LEAD.

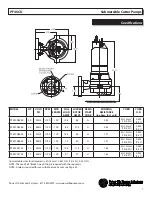

FIGURE 4 - THREE PHASE 230 VOLT AC

Power Cable

Motor Lead Number

G (Ground)

G

L1 or W1

1 & 7

L2 or W2

2 & 8

L3 or W3

3 & 9

T4, T5 & T6 Together

FIGURE 4 - THREE PHASE 460 VOLT AC

Power Cable

Motor Lead Number

Green (Ground) Green

L1 or W1

1

L2 or W2

2

L3 or W3

3

T4 & T7 Together

T5 & T8 Together

T6 & T9 Together

FIGURE 4

MOISTURE & TEMPERATURE SENSORS

Control Cable

Lead Number

G (Ground)

Green

S1

P1 (Temp Sensor) In

series with starter coil

S2

P2 (Temp Sensor) In

series with starter coil

W1

W1 (Moisture Sensor)

IMPORTANT! - All parts must be

clean before reassembly.

Handle seal parts with extreme

care. DO NOT damage lapped

surfaces.

Shaft Seal Service:

Lower Seal -

With oil drained, expose

lower shaft seal (10) for inspection, by

first disconnecting power, remove cap

screws (45) and washers (47) from volute

(40). Lift motor assembly from volute and

remove impeller.

Service

PF4SCC, 4SCD, 4SCE, 4SCF

Submersible Cutter Pumps