20

Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

Remove retaining ring (10D), spring (10C)

and rotating member (10B) from shaft

(See Figure 5). Inspect seal for signs of

uneven wear pattern on stationary, chips

and scratches on either face.

DO NOT

interchange seal components, replace

the entire shaft seal (10). If replacing

seal, remove stationary (10A) from

intermediate (2) by prying out with flat

screw driver.

Upper Seal -

Remove screws (17),

washers (18) and intermediate (2) from

motor housing (1). Do not damage o-ring

(21) or sensor probe (36). Remove snap

ring (25), retaining ring (9D), spring (9C)

and rotating member (9B) from shaft. If

replacing seal, remove stationary (9A)

from bearing bracket (3) by prying out

with flat screw driver.

Reassembly:

Lower seal - Clean and oil seal cavity in

intermediate (2).

Lightly oil (

The use of grease is

NOT recommended

) outer surface

of stationary member (10A), press

stationary member (10A) firmly into

intermediate (2) using a seal tool,

nothing but the seal tool is to come in

contact with seal face.

Important! Hammering on the

seal pusher will damage the seal

face.

Make certian the stationary member is

in straight and that the rubber ring is

not out of it’s groove. Lightly oil (

The use

of grease is NOT recommended

), shaft

and inner surface of bellows on rotating

member (10B). With lapper surface facing

intermediate (2), slide rotating member

(10B) onto shaft using the seal tool

until lapped faces of (10B) and (10A) are

together.

Place spring (10C) over shaft and in

place on rotating member (10B) making

certain it is seated in the retainer and not

cocked or resting on bellows tail. Slide

retaining ring (10D) over shaft and let

rest on spring (10C).

Upper Seal - Clean and oil seal cavity

in bearing bracket (3). Lightly oil (

The

use of grease is NOT recommended

)

outer surface of stationary member (9A),

press stationary member (9A) firmly

into bearing bracket (3), using seal tool,

nothing but the seal tool is to come in

contact with seal faces. Be certain the

stationary member is in straight and that

the rubber ring is not out of it’s groove.

Lightly oil (

The use of grease is NOT

recommended

) the shaft and inner

surface of bellows on rotating member

(9B). With lapped surface facing bearing

bracket (3), slide rotating member (9B)

onto shaft, using seal tool until lapped

faces of (9B) and (9A) are together. Place

spring (9C) over shaft and in place on

rotating member (9B), being certain it

is seated in retainer and not cocked or

resting on bellows tail. Slide retaining

ring (9D) over shaft and let rest on spring

(9C) and replace snap ring (25) onto

shaft.

Motor & Bearing Service:

Bearings -

Slide motor assembly from

motor housing (1). Remove bearing (12)

from motor shaft using a wheel puller.

Remove snap ring (8) or screws (19)

with washers (20) and bearing bracket

(3). Remove snap ring (15) from shaft.

Remove bearing (11) from shaft, if

required, using a wheel puller.

Bearing Reassembly

- Be careful Not to

damage the rotor or the shaft threads.

On some models

, first slide bearing cap

(4) onto shaft. Apply adhesive compound

to the shaft and press lower bearing (11)

on the motor shaft.

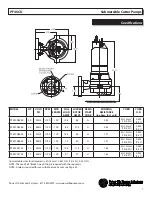

Service

Figure 5

PF4SCC, 4SCD, 4SCE, 4SCF

Submersible Cutter Pumps

Note:

Upper stationary as

shown for 100Fr Mtrs

only, 132Fr & 180Fr Mtrs

have design similar to

stationary on lower seal.