Automatic boiler for wood pellets

Instructions for installation and operation

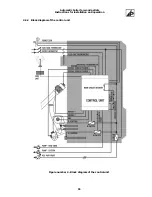

7) Priority heating of hot service water. Excellent properties of this function can fully be

used, if the boiler is connected as per the figure number 15. This function will ensure

heating of hot service water within a minimum time interval. If the boiler sends a request

to heat the hot service water (temperature of water will get reduced and the boiler's

thermostat will switch in), the control unit will:

- stop the circulation pump in the central heating system

- the boiler will start working as per the programme P6 - item 1 (should be adjusted to the

maximum power output)

- the servo actuator will re-route the water from the whole system into the

water heater

- when the temperature of the boiler water is > 60°C, the control unit will turn the boiler's

pump on

- the automatic operation of the boiler will be resumed (original state) after the water has

been heated (the boiler's thermostat will be turned off)

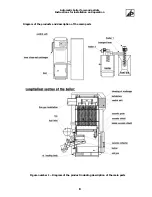

4.3 BURNER FURNACE INCLUDING THE FEEDER 2 WITH INDEPENDENT DRIVE

A diagram of the burner furnace is shown as a part of the figure number 1 and the burner furnace

consists of the following parts:

- The body of the burner as such including the built-in transport route (spiral-chute feeder number 2

including drive), an extension piece to install a flexible hose and an extension piece to install a fan.

- A flexible hose made from non-flammable material.

- Combustion fan.

- Two electric resistance coils for automatic ignition (special equipment).

Body of the burner

– is a box-type weldment made from highly alloyed material with the bottom

oblique input of fuel. The fuel is transported by a built-in spiral-chute

feeder 2

driven by an electric

motor with a gearbox.

Assembly of slotted nozzles ensures supply of combustion air in order to reach controlled and

perfect combustion of the supplied fuel during the time when the fuel is in the combustion space of

the burner.

The spent fuel is then shifted through the overflow edge of the combustion space into the ash

pan.

The inside space of the burner's body is connected to the

air fan

the revolutions of which may

be widely regulated (see the paragraph on the control unit) in connection with the required power

output of the boiler or with the fuel type used.

The

flexible hose

to feeder 2 made from non-flammable material interconnects both feeders

and is thus a part of the transport routes for fuel.

The flexible hose has to be installed so that it:

- does not form considerably rippled folds which block smooth movement of the fuel and

must be built-in under an angle min. 70

°

(to horizontal plane).

- its fixation on both tube extension pieces has to be tight.

18

Содержание KP 10

Страница 1: ......