0507060400/010920/M DraftMax Basic | DraftMax Ultra

15

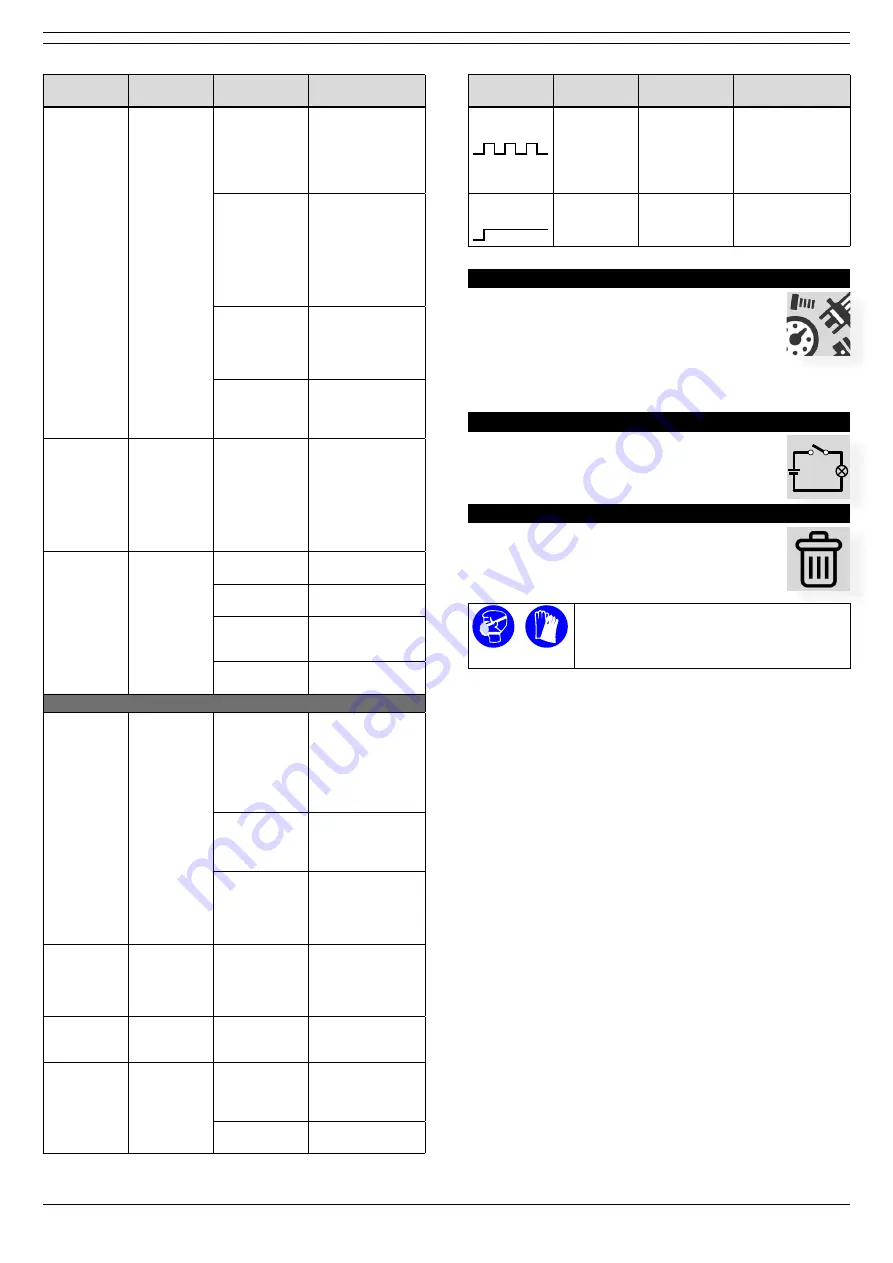

Symptom

Problem

Possible

cause

Solution

Poor

extraction

capacity

Downdraft

table does

not function

properly

Filter cartridges

clogged

Replace both filter

cartridges (refer to

par. 6.2.1).

Replace the HEPA

filter as well (refer

Pressure gauge

defective

(indicates value

below 800 Pa)

Replace the

pressure gauge and

the filter cartridges

(refer to par.

Replace the HEPA

filter as well (refer

Inverted

direction of

rotation of the

motor

Invert the

connection of the

phases to change

the direction of

rotation

Pre and/or

main spark

arresters

polluted

Clean the spark

arresters

Dust or

smoke

coming out of

the outlet

Pollution of

the facility

Filter

cartridge(s)

ripped

Replace both filter

cartridges (refer to

par. 6.2.1) and

clean the outlet

grid.

Replace the HEPA

filter as well (refer

Working light

not working

No light

Main switch off

Turn on main

switch

Cable is not

connected

Connect the cable

Fluorescent

light is

defective

Replace fluorescent

light

Fuse defective

Check fuse F4 and

replace if necessary

DraftMax Ultra only

The fan does

not start

The

downdraft

table does

not function

Automatic

start/stop

(movement

sensor or

welding cable

sensor) not

connected

Connect cable of

automatic start/

Sensor of

movement

sensor

defective

Replace the sensor

Welding cable

sensor not

connected

Connect clamp of

welding cable

sensor to mass

cable of welding

machine

Irregular filter

cleaning

One of the

filter

cartridges is

not being

cleaned

One of the

membrane

valves defective

Replace both

membrane valves

Poor

extraction

capacity

No filter

cleaning

Membrane

valve(s)

defective

Replace both

membrane valves

Button

MANUAL

CLEANING

does not

react

No filter

cleaning

Button

MANUAL

CLEANING

defective

Replace button

MANUAL

CLEANING

PC board

defective

Replace PC board

Symptom

Problem

Possible

cause

Solution

Signal of

alarm light:

Downdraft

table does

not function

properly

Filter cartridges

clogged

Replace both filter

cartridges (refer to

par. 6.2.1).

Replace the HEPA

filter as well (refer

Signal of

alarm light:

Filter cleaning

system does

not function

No compressed

air available

Connect/repair the

compressed air

supply

8

SPARE PARTS

8.1

Filter unit

The following spare parts are available for the

downdraft table;

- refer to exploded view Fig. IV on page 18 and spare parts

9

ELECTRICAL DIAGRAM

Refer to the separately supplied electrical diagram.

10

DISPOSAL

Dismantling and disposal of the downdraft table

must be done by qualified persons.

Personal protective equipment (PPE)

Wear respiratory protection and protective

gloves when you dismantle and dispose of

the unit.

10.1 Dismantling

To safely dismantle the downdraft table, obey the safety

instructions that follow.

Before dismantling of the downdraft table:

- disconnect it from the mains

- disconnect it from the compressed air

- clean the outside

During dismantling of the downdraft table:

-

make sure that the area is sufficiently ventilated, e.g. by a

mobile ventilation unit

After dismantling of the downdraft table:

- clean the dismantling area

10.2 Disposal

Dispose of the pollutants and dust, together with the used

filter cartridges, in a professional manner in accordance with

federal, state or local regulations.