Adjustment

13 - 3

13

.05

Checking and adjustment aids

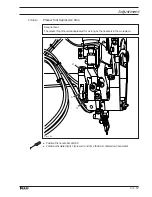

The necessary needle bar positions can be fixed exactly by blocking

holes

1

and

3-6

.

●

Turn the handwheel until the needle bar is approximately in the position required.

●

Insert the adjustment pin into the relevant hole provided and apply pressure.

●

Turn the handwheel slightly forwards and backwards until the adjustment pin engages in

the crank slot behind the bearing plate and thus blocks the machine.

Hole 1

=

0.6 mm past the top dead center of the needle bar (0.6 past TDC)

Hole 3

=

0.6 mm past the bottom dead center of the needle bar (0.6 past BDC)

Hole 4

=

1.8 mm past the bottom dead center of the needle bar (1.8 past BDC)

Hole 5

=

top dead center of the needle bar (TDC)

Hole 6

=

4 mm past the bottom dead center of the needle bar (4 past BDC)

Fig. 13 - 02

1

5

6

4

3

Содержание 3574-2/02

Страница 1: ...296 12 17 977 Betriebsanleitung engl 11 96 3574 2 02 Instruction Manual...

Страница 89: ...Notes...