Engine Operation

i06101183

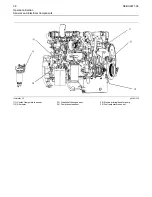

Engine

Operation

Proper

operation

and

maintenance

are

key

factors

in

obtaining

the

maximum

life

and

economy

of

the

engine.

If

the

directions

in

the

Operation

and

Maintenance

Manual

are

followed,

costs

can

be

minimized

and

engine

service

life

can

be

maximized.

The

time

that

is

needed

for

the

engine

to

reach

normal

operating

temperature

can

be

less

than

the

time

taken

for

a

walk-around

inspection

of

the

engine.

The

engine

can

be

operated

at

the

rated

rpm

after

the

engine

is

started

and

after

the

engine

reaches

operating

temperature.

The

engine

will

reach

normal

operating

temperature

sooner

during

a

low

engine

speed

(rpm)

and

during

a

low-power

demand.

This

procedure

is

more

effective

than

idling

the

engine

at

no

load.

The

engine

should

reach

operating

temperature

in

a

few

minutes.

Avoid

excess

idling.

Excessive

idling

causes

carbon

buildup,

engine

slobber

and

soot

loading

of

the

Diesel

Particulate

Filter

(DPF).

These

issues

are

harmful

to

the

engine.

Gauge

readings

should

be

observed

and

the

data

should

be

recorded

frequently

while

the

engine

is

operating.

Comparing

the

data

over

time

will

help

to

determine

normal

readings

for

each

gauge.

Comparing

data

over

time

will

also

help

detect

abnormal

operating

developments.

Significant

changes

in

the

readings

should

be

investigated.

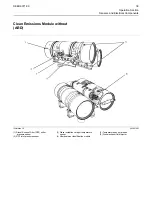

Engine

Operation

and

the

Aftertreatment

System

The

exhaust

gases

and

hydrocarbon

particles

from

the

engine

first

pass

through

Diesel

Oxidation

Catalyst

(DOC).

Some

of

the

gasses

and

matter

are

oxidized

as

they

pass

through

the

DOC.

The

gasses

then

pass

through

the

Diesel

Particulate

Filter

(DPF).

The

DPF

collects

the

soot

and

any

ash

that

is

produced

by

the

combustion

in

the

engine.

During

regeneration,

the

soot

is

converted

into

a

gas

and

the

ash

remains

in

the

DPF.

The

gasses

finally

pass

through

the

Selective

Catalytic

Reduction

(SCR).

Before

the

gasses

pass

through

the

SCR,

Diesel

Exhaust

Fluid

(DEF)

is

injected

into

the

gas

stream.

The

DEF

is

controlled

by

the

Pump

Electronic

Unit

(PEU).

The

mixtures

of

DEF

and

the

exhaust

gas

pass

through

the

SCR

reducing

the

NOx

in

the

exhaust

emissions.

The

engine

software

will

control

the

amount

of

DEF

that

will

be

required

in

order

to

keep

the

exhaust

emission

compliant.

This design of DPF will require a service

maintenance interval. Refer to this Operation and

Maintenance Manual, “Maintenance Interval

Schedule” for more information. The DPF can be

expected to function properly for the useful life of the

engine (emissions durability period), as defined by

regulation, subject to prescribed maintenance

requirements being followed.

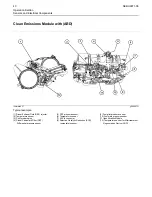

i04038637

Engaging

the

Driven

Equipment

1.

Operate the engine at one-half of the rated rpm,

when possible.

2.

Engage the driven equipment without a load on the

equipment, when possible.

Interrupted starts put excessive stress on the drive

train. Interrupted starts also waste fuel. To get the

driven equipment in motion, engage the clutch

smoothly with no load on the equipment. This

method should produce a start that is smooth and

easy. The engine rpm should not increase and the

clutch should not slip.

3.

Ensure that the ranges of the gauges are normal

when the engine is operating at one-half of the

rated rpm. Ensure that all gauges operate

properly.

4.

Increase the engine rpm to the rated rpm. Always

increase the engine rpm to the rated rpm before

the load is applied.

5.

Apply the load. Begin operating the engine at low

load. Check the gauges and equipment for proper

operation. After normal oil pressure is reached and

the temperature gauge begins to move, the engine

may be operated at full load. Check the gauges

and equipment frequently when the engine is

operated under load.

Extended operation at low idle or at reduced load

may cause increased oil consumption and carbon

buildup in the cylinders. This carbon buildup

results in a loss of power and/or poor

performance.

52

SEBU9071-06

Содержание 2206F-E13TA

Страница 126: ......

Страница 128: ...SEBU9071 2020 Perkins Engines Company Limited All Rights Reserved 128 December 2020 ...