Coolant System

Completely fill the cooling system before storage.

Refer to this Operation and Maintenance Manual,

“Fluid Recommendations” for more information about

coolants.

Aftertreatment

The engine must be allowed to perform a Diesel

Exhaust Fluid (DEF) purge before the battery

disconnect switch is turned off. Some applications,

the engine can be equipped with delayed engine

shutdown. Allow 2 minutes after the engine has

stopped before disconnecting the battery disconnect

switch.

The exhaust outlet of the aftertreatment must be

capped. In order to prevent damage to the exhaust

outlet connection during storage, the weight of the

CEM must not act on the exhaust outlet.

1.

Ensure normal engine shutdown, allow the DEF to

be purged. Do not disconnect the battery

disconnect switch, allow 2 minutes after key off

before disconnection.

2.

Fill the tank with DEF that meet all the requirement

defined in ISO 22241-1.

3.

Ensure that all DEF lines and electrical connection

are connected prior to prevent crystal from

forming.

4.

Ensure that the DEF filler cap is correctly installed.

Remove Engine from Storage

1.

Remove all outside protective covers.

2.

Change the oil and filters.

3.

Check the condition of the fan and alternator belts.

Replace the belts, if necessary. Refer to this

Operation and Maintenance Manual, “Belts -

Inspect/Adjust/Replace” for the correct procedure.

4.

Replace the fuel filter elements.

5.

Remove the plastic covers from the air cleaner

elements.

6.

Use a bar or a turning tool in order to turn the

engine in the normal direction of rotation. The

procedure ensures that no hydraulic locks or

resistance exist.

7.

Before starting the engine, remove the valve cover

or covers. Put a large amount of engine oil on the

camshaft, cam followers, and valve mechanism in

order to prevent damage to the mechanism.

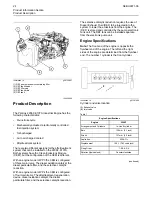

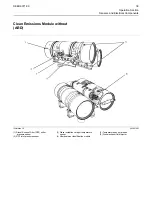

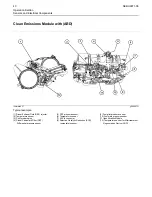

Illustration 32

g03854041

Typical example

(1) Plugs

8.

If an engine is stored for more than 1 year, Perkins

recommends Pre lubrication of the engine in order

to avoid dry starting. Use a suitable pump in order

to put engine oil into the engine oil system.

The pump will need to create a minimum pressure

within the engine of 0.25 bar (3.6 psi). This

pressure is needed for 15 seconds in order to

lubricate the internal surfaces.

Remove one of the plugs shown in illustration 32

in order to connect to the engine oil system. The

connection required is 9/16" x 18 tpi. Ensure that

the correct oil specification is used, refer to this

Operation and Maintenance Manual, “Fluid

Recommendations” for more information. After the

engine internal surfaces have been lubricated,

remove connector and install plug (1). Tighten plug

to a torque of 30 N·m (265 lb in). Perkins

recommends that the procedure must be

performed in a minimum ambient temperature of

10° C (50° F).

9.

Check the condition of all rubber hoses. Replace

any worn hoses. Replace any damaged hoses.

34

SEBU9071-06

Содержание 2206F-E13TA

Страница 126: ......

Страница 128: ...SEBU9071 2020 Perkins Engines Company Limited All Rights Reserved 128 December 2020 ...