4.

.Remove the oil level gauge to check the oil level.

Maintain the oil level between the ADD and FULL

marks on the side of the oil level gauge.

i06972463

Engine

Valve

Lash

-

Check

Ensure that the engine cannot be started while

this maintenance is being performed. To help pre-

vent possible injury, do not use the starting motor

to turn the flywheel.

Hot engine components can cause burns. Allow

additional time for the engine to cool before

measuring/adjusting valve lash clearance.

NOTICE

Only qualified service personel should perform this

maintenance. Refer to the Service Manual or your au-

thorized Perkins dealer or your Perkins distributor for

the complete valve lash adjustment procedure.

Operation of Perkins engines with incorrect valve

lash can reduce engine efficiency, and also reduce

engine component life.

The initial valve lash adjustment on new engines,

rebuilt engines, or remanufactured engines is

recommended only on engine ratings 330 kW

(442 hp) and greater. The adjustment is necessary

due to the initial wear of the valve train components

and to the seating of the valve train components.

This maintenance is recommended as part of a

lubrication and preventive maintenance schedule to

help provide maximum engine life. For engine ratings

less than 330 kW (442 hp), the initial valve lash

adjustment is not necessary.

Note:

All engine ratings must have the engine valve

lash performed at 2500 hours.

Ensure that the engine is stopped before measuring

the valve lash. To obtain an accurate measurement,

allow the valves to cool before this maintenance is

performed.

During valve adjustment, visibly inspect the valve

train of wear or damage.

Refer to Systems Operation, Testing and Adjusting,

“Engine Valve Lash - Inspect/Adjust” for more

information.

i06133832

Fuel

System

-

Prime

NOTICE

Do not allow dirt to enter the fuel system. Thoroughly

clean the area around a fuel system component that

will be disconnected. Fit a suitable cover over discon-

nected fuel system component.

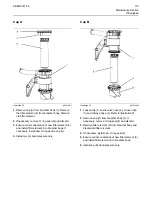

Illustration 87

g03820371

(1) Fuel priming pump

(2) Fuel priming switch

1.

The fuel system can be primed from the keyswitch

or from a remote mounted switch (2).

2.

Turn the fuel priming switch (2) to the ON position.

Hold the fuel priming switch in the ON position for

2 minutes.

3.

Verify that the water separator is full of fuel.

4.

If the water separator is not full of fuel, turn the fuel

priming switch OFF and then turn the engine start

switch ON. This action will cycle the fuel priming

pump again.

5.

When the water separator is full of fuel, attempt to

start the engine. If the engine starts and the

engine runs rough or the engine misfires, operate

at low idle until the engine is running smoothly. If

the engine cannot be started, or if the engine

continues to misfire or smoke, repeat Step 1.

108

SEBU9071-06

Содержание 2206F-E13TA

Страница 126: ......

Страница 128: ...SEBU9071 2020 Perkins Engines Company Limited All Rights Reserved 128 December 2020 ...