12

PUMP BELT ADJUSTMENT

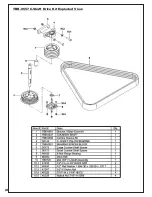

The Pump Belt should be checked periodically for the correct tension. There should be 1” of movement for 10 lbs. of

tension applied to the center of the Belt. To adjust the Belt, follow the steps below and refer to the figures below:

1. Use a floor jack to raise the machine off the ground and blocks to support the chassis and deck.

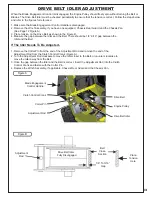

2. Remove the Chassis Rear Guard and the Chassis Pan (Figure A).

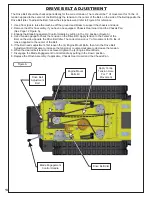

3. Check the tension on the Belt using a belt tension gauge (Figure B).

4. If the belt tension needs adjustment, loosen the Pump Belt Idler Bolt (Figure C).

5. Push the Pump Belt Idler forward to increase the tension, then tighten the Pump Belt Idler Bolt.

6. Check the tension on the belt again, and adjust the Pump Belt Idler if necessary.

7. Replace the Chassis Rear Guard and the Chassis Pan.

Remove Chassis

Rear Guard

Remove

Chassis

Pan

Pump Belt

Pump Belt

Idler

Apply

10 lbs.

Tension

Here

For 1” Of

Movement

Pump Belt Idler Bolt Location

Relative To Brush Blazer

Direction To Move Pump

Belt Idler Bolt To Increase

The Pump Belt Tension

Figure A

Figure C

Figure B

Содержание BRUSH BLAZER TBB-3002

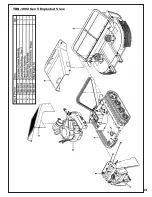

Страница 23: ...23 TBB 3002 Gen 5 Exploded View...

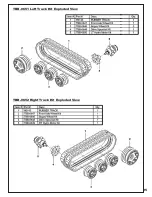

Страница 24: ...24 TBB 0671 Complete Chassis Assembly Exploded View...

Страница 25: ...25 TBB 0651 Left Track Kit Exploded View TBB 0652 Right Track Kit Exploded View...

Страница 26: ...26 TBB 0657 C Shaft Drive Kit Exploded View...

Страница 27: ...27 TBB 0665 Hydraulic Drive Kit Exploded View...

Страница 28: ...28 TBB 0628 Complete Deck Assembly Exploded View...

Страница 29: ...29 TBB 0620 Blade Shaft Flange Hub Kit Exploded View...

Страница 30: ...30 TBB 0629 Blade Kit Single Shaft Exploded View TBB 0606 Blade Shaft Sheave Kit Exploded View...

Страница 31: ...31 TBB 0600 Deck Hood Assembly Exploded View...

Страница 32: ...32 TBB 0601 Chassis Hood Assembly Exploded View...

Страница 33: ...33 TBB 0601 Chassis Hood Assembly Exploded View...

Страница 34: ...34 TBB 0675 Right FRS Kit Exploded View...

Страница 35: ...35 TBB 0676 Left FRS Kit Exploded View...

Страница 36: ...36 TBB 0672 Hydro Tank Kit Exploded View TBB 0680 Dash Kit Briggs Stratton Exploded View...

Страница 37: ...37 TBB 0674 Dash Assembly Exploded View...

Страница 38: ...38 TBB 0687 Briggs Stratton 36HP Vanguard Engine Kit Exploded View...

Страница 39: ...39...