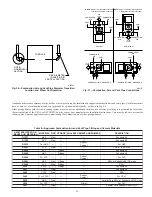

NOTE:

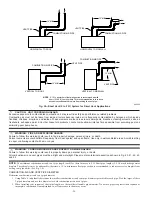

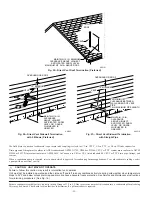

Do not count elbows or pipe sections in terminations or within furnace. See shaded areas in Fig. 40, 41, 42, 43, and 44.

EXAMPLE:

An 036080 size furnace located in Indianapolis, elevation 650 ft above sea level, could be installed in an application requiring 3 elbows

and 32 ft of vent pipe, along with 5 elbows and 34 ft of combustion-air pipe. Table 9 indicates this application would allow a 2-in. diameter

vent pipe, but require a 2-1/2 in. diameter combustion air pipe (2-in. pipe is good for 35 ft with 3 elbows, but only 30 ft with 5 elbows).

Therefore, 2-1/2 in. diameter pipe must be used for both vent and combustion-air pipes since larger required diameter must always be used

for both pipes. If same installation were in Albuquerque, elevation 5250 ft above sea level, installation would require 2-1/2 in. vent pipe

and combustion-air pipe. At 5001- to 6000-ft elevation, 2-in. pipe is only good for 17 ft with 5 elbows, and 2-1/2 in. pipe is good for 70

ft with 5 elbows.

COMBUSTION-AIR AND VENT PIPE ATTACHMENT

NOTE:

All pipe joints must be cemented except attachment of combustion-air pipe to inlet housing connection, since it may be necessary to

remove pipe for servicing.

1. Attach combustion-air pipe as follows:

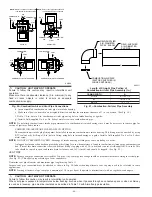

a. Determine location of combustion-air intake pipe connection to combustion-air intake housing as shown in Fig. 37 for application.

b. Reposition combustion-air intake housing plug fitting in appropriate unused intake housing connection.

c. If required per Table 9, insert perforated disk assembly (factory-supplied in loose parts bag) in intake housing where combustion-air

intake pipe will be connected. If half disk set is required, install with shoulder of disk against stop in combustion-air inlet.

d. Install pipe support (factory-supplied in loose parts bag) into selected furnace casing combustion-air pipe hole. Pipe support should be

positioned at bottom of casing hole.

e. Insert 2-in. diameter pipe into intake housing.

NOTE:

A 2-in. diameter pipe must be used within the furnace casing. Make all pipe diameter transitions outside furnace casing.

f. Install casing hole filler cap (factory-supplied in loose parts bag) in unused combustion-air pipe casing hole.

g. Drill a 1/8-in. hole in 2-in. combustion-air pipe using hole in intake housing as a guide.

h. Install a field-supplied No. 6 or No. 8 sheet metal screw into combustion-air pipe.

NOTE:

DO NOT OVERTIGHTEN SCREW. Breakage of intake housing or fitting may cause air leakage to occur.

NOTE:

Do not attach combustion-air intake pipe permanently to combustion-air intake housing since it may be necessary to remove pipe for

service of igniter or flame sensor.

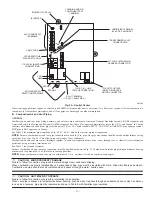

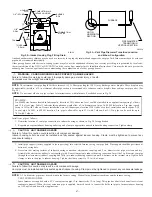

COMBUSTION-AIR INTAKE HOUSING PLUG FITTING

The combustion-air intake plug fitting must be installed in unused combustion-air intake housing. This fitting must be attached by using

RTV sealant, or by drilling a 1/8-in. hole in fitting, using hole in intake housing as a guide. Install a field-supplied No. 6 or No. 8 sheet

metal screw.

NOTE:

DO NOT OVERTIGHTEN SCREW. Breakage of intake housing or fitting may cause air leakage to occur.

A plugged drain connection has been provided on this fitting for use when moisture is found in combustion-air intake pipe and combustion

box.

NOTE:

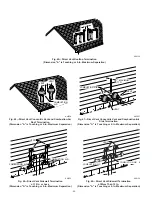

Moisture in combustion-air intake may be result of improper termination. Ensure combustion-air intake pipe termination is similar to that

shown in Fig. 40, 41, 42, 43 or 44 so it will not be susceptible to areas where light snow or other sources of moisture could be pulled in.

If use of this drain connection is desired, drill out fitting’s tap plug with a 3/16-in. drill and connect a field-supplied 3/8-in. tube. This tube

should be routed to open condensate drain for furnace and A/C (if used), and should be trapped. (See Fig. 39.)

2. Attach vent pipe as follows:

a. Determine location of vent pipe connection to inducer housing as shown in Fig. 37 for application.

b. Reposition neoprene inducer housing outlet cap and clamp to appropriate unused inducer housing connection. Tighten clamp.

CAUTION: UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit component damage.

Inducer housing outlet cap must be installed and fully seated against inducer housing. Clamp must be tightened to prevent any

condensate leakage.

c. Install pipe support (factory-supplied in loose parts bag) into selected furnace casing vent pipe hole. Pipe support should be positioned

at bottom of casing hole.

CAUTION: UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit component damage.

Vent pipe must be installed and fully seated against inducer housing internal stop. Clamp must be tightened to prevent any condensate

leakage.

NOTE:

A 2-in. diameter pipe must be used within the furnace casing. Make all pipe diameter transitions outside furnace casing.

d. Be certain that mating surfaces of inducer housing connection, elastomeric coupling, and 2-in. diameter vent pipe are clean and dry.

Assemble the elastomeric (rubber) vent coupling (with 2 loose clamps) onto inducer housing connection. Insert the 2-in. diameter vent

pipe through the elastomeric (rubber) coupling and fully into inducer housing connection until it bottoms on the internal stop. Tighten

both clamps to secure the pipe to inducer housing. Tighten the clamp screws to 15 in.-lb. of torque.

—37—

→

→

Содержание PG9MAA

Страница 70: ... 70 ...

Страница 71: ... 71 ...

Страница 72: ... 2005 Payne Heating Cooling 7310 W Morris St Indianapolis IN 46231 72 impg9m10 Catalog No 53PG 9M29 ...