NOTE:

See label on vent extension pipe for proper installation. This pipe may be shortened if an elbow is used to connect vent extension tube

to field-installed vent pipe.

5. Working from furnace to outside, cut pipe to required length(s).

6. Deburr inside and outside of pipe.

7. Chamfer outside edge of pipe for better distribution of primer and cement.

8. Clean and dry all surfaces to be joined.

9. Check dry fit of pipe and mark insertion depth on pipe.

NOTE:

It is recommended that all pipes be cut, prepared, and preassembled before permanently cementing any joint.

10. After pipes have been cut and preassembled, apply generous layer of cement primer to pipe fitting socket and end of pipe to insertion mark.

Quickly apply approved cement to end of pipe and fitting socket (over primer). Apply cement in a light, uniform coat on inside of socket

to prevent buildup of excess cement. Apply second coat.

11. While cement is still wet, twist pipe into socket with 1/4 turn. Be sure pipe is fully inserted into fitting socket.

12. Wipe excess cement from joint. A continuous bead of cement will be visible around perimeter of a properly made joint.

13. Handle pipe joints carefully until cement sets.

14. Support vent piping a minimum of every 5 ft (3 ft for SDR-21 or -26 PVC) using perforated metal hanging strap.

15. Slope vent pipe toward furnace a minimum of 1/4-in. per linear ft with no sags between hangers.

16. Use appropriate methods to seal openings where vent pipe passes through roof or sidewall.

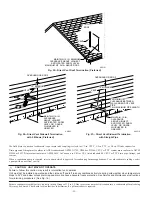

EXTENDED EXPOSED SIDEWALL PIPES

Sidewall vent pipe termination may be extended beyond area shown in Fig. 56 in outside ambient by insulating pipe as indicated in Table 12.

1. Determine vent pipe diameter, as stated above, using total pipe length and number of elbows.

2. Find appropriate temperature for your application and furnace model using winter design temperature (used in load calculations).

3. Determine required insulation thickness for exposed pipe lengths.

NOTE:

Pipe length (ft) specified for maximum pipe lengths located in unconditioned spaces cannot exceed total allowable pipe length as specified

in Table 11.

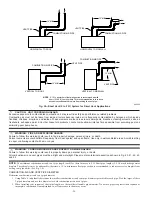

Fig. 54—Short Vent (5 to 8 Ft) System for Non-Direct Vent Applications

A96189

HORIZONTAL TO ROOF

HORIZONTAL TO SIDEWALL

VERTICAL TO SIDEWALL

VERTICAL TO ROOF

VENT PIPE

VENT PIPE

VENT PIPE

VENT PIPE

12

″

MIN

12

″

MIN

12

″

MIN

12

″

MIN

NOTE: A 12-In. minimum offset pipe section is recommended with

short (5 to 8 ft) vent systems. This recommendation is to reduce

excessive condensate droplets from exiting the vent pipe.

—48—

Содержание PG9MAA

Страница 70: ... 70 ...

Страница 71: ... 71 ...

Страница 72: ... 2005 Payne Heating Cooling 7310 W Morris St Indianapolis IN 46231 72 impg9m10 Catalog No 53PG 9M29 ...