www.parweld.com

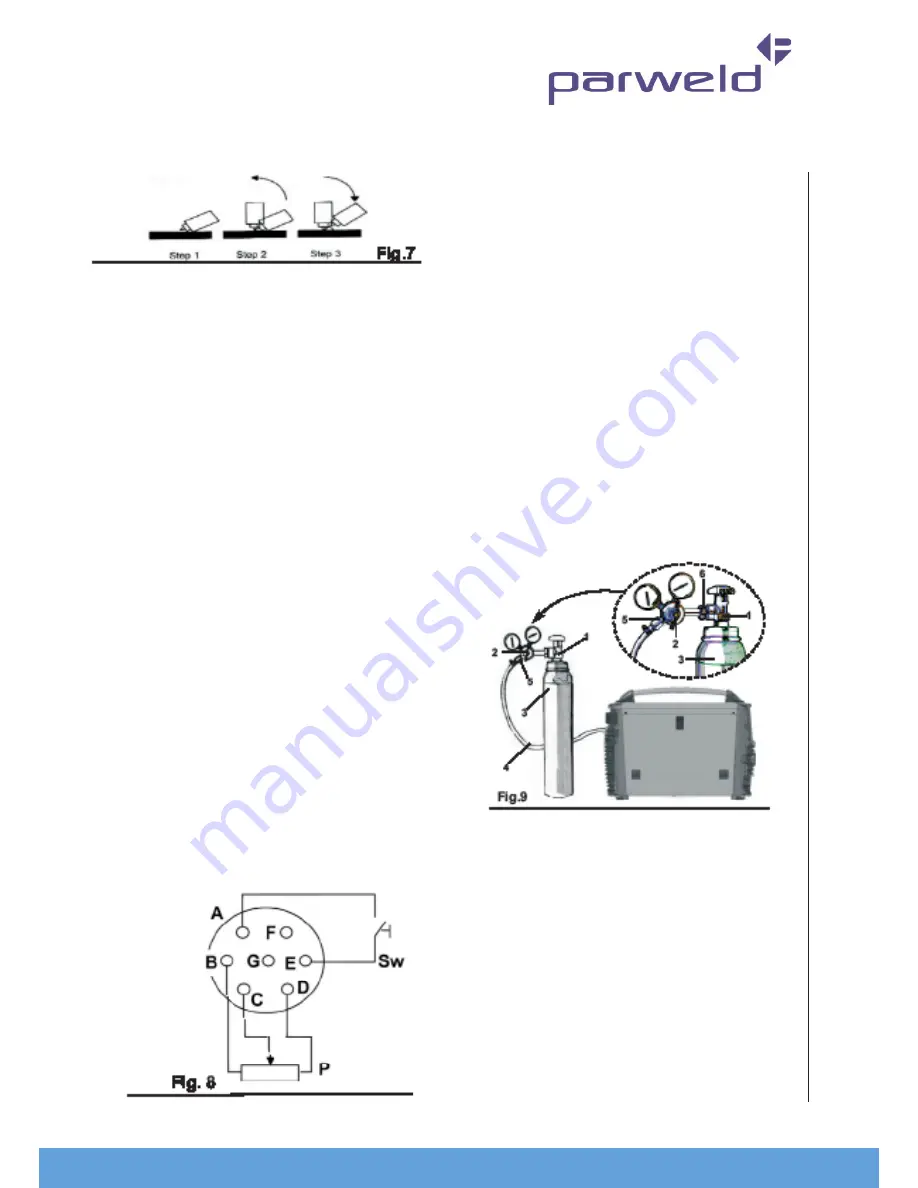

At this stage, ignite the arc by moving the electrode

away from the workpiece a few millimetres (step 3

of fig.7). Weld maintaining the same distance from

the weld pool, whilst keeping the torch trigger held

down. Release the button to interrupt the welding

process.

16.POWER CONNECTOR

Before connecting the

machine check the tension, number of phases and

the power supply frequency. The admissible power

supply is indicated in the ‘Specific Techniques’

section on page 5 of this manual and on the

information plate on the machine. Check that the

earth of the welder has been connected correctly.

Furthermore, make sure that the plug provided

with the equipment is compatible with the local grid

sockets. Make sure that the power supply provides

sufficient power for the machine to function (tension

ranges) The power supply grid protection devices

to be used are listed in the ‘Specific techniques’

section of the present manual.

The machine is provided with a specific power cable

that does not usually require an extension lead; in

the event an extension lead is required, use one of

the same capacity [Length/Cross section] or higher

than the machine in use, according to the length of

the cable. A 2.5 mm² three-pole cable + earth, of the

same size or larger.

17. REMOTE CONNECTION

Figure 8 shows the connections of the remote

connector (20 of fig 1).

Where: Sw is the torch trigger

P is the potentiometer for controlling the current.

17.1 REMOTE CONTROL OF THE WELDING

CURRENT

With remote connector 20 in Fig. 1, it is possible to

adjust the current near to the point where the welding

is being carried out. To do so, it is necessary to create

a connection with potentiometer P, shown in figure 8.

The value of the potentiometer is not a critical factor:

between 2.2kOhm and 10kOhm 1/2W can be used.

Turn the potentiometer and select the welding current

in a range between zero and the set value.

18. CONNECTING THE OUTPUTS

Connection of

the welding cables occurs via a Dinse quick-connect

system with appropriate connectors

19. CONNECTING THE GAS CYLINDER AND THE

GAS REGULATOR

For TIG and MIG welding only. For MMA welding, skip

this paragraph entirely.

1. Connect the pressure regulator (2) to the cylinder

(3). Make sure the regulator is suitable for the cylinder

pressure. Attach the connector nut (6) of the regulator

(2) to the cylinder (3). (Do not screw too tightly;

excessive force could damage the valve (1) of the

cylinder (3).)

2. Connect the gas tube (4) to the regulator (2) and

secure with a cable tie (5).

3. Make sure that the gas tube is connected to the

welder correctly.

4. Open the valve (1) of the cylinder (3). Press the

torch trigger and check the gas is flowing correctly. To

carry out this operation release the clutch of the motor.

20

Содержание DP323C

Страница 1: ...ISSUE 2 User Manual DP323C...

Страница 3: ...CONTENTS 2...

Страница 4: ...www parweld com 3...

Страница 5: ...www parweld com 4...

Страница 6: ...www parweld com 5...

Страница 9: ...www parweld com 8 3 LOADING THE WELDING WIRE To load the welding wire follow these instructions...

Страница 24: ...www parweld com 23...

Страница 26: ...www parweld com 25...

Страница 27: ...www parweld com 26 Spare Parts 26...