www.parweld.com

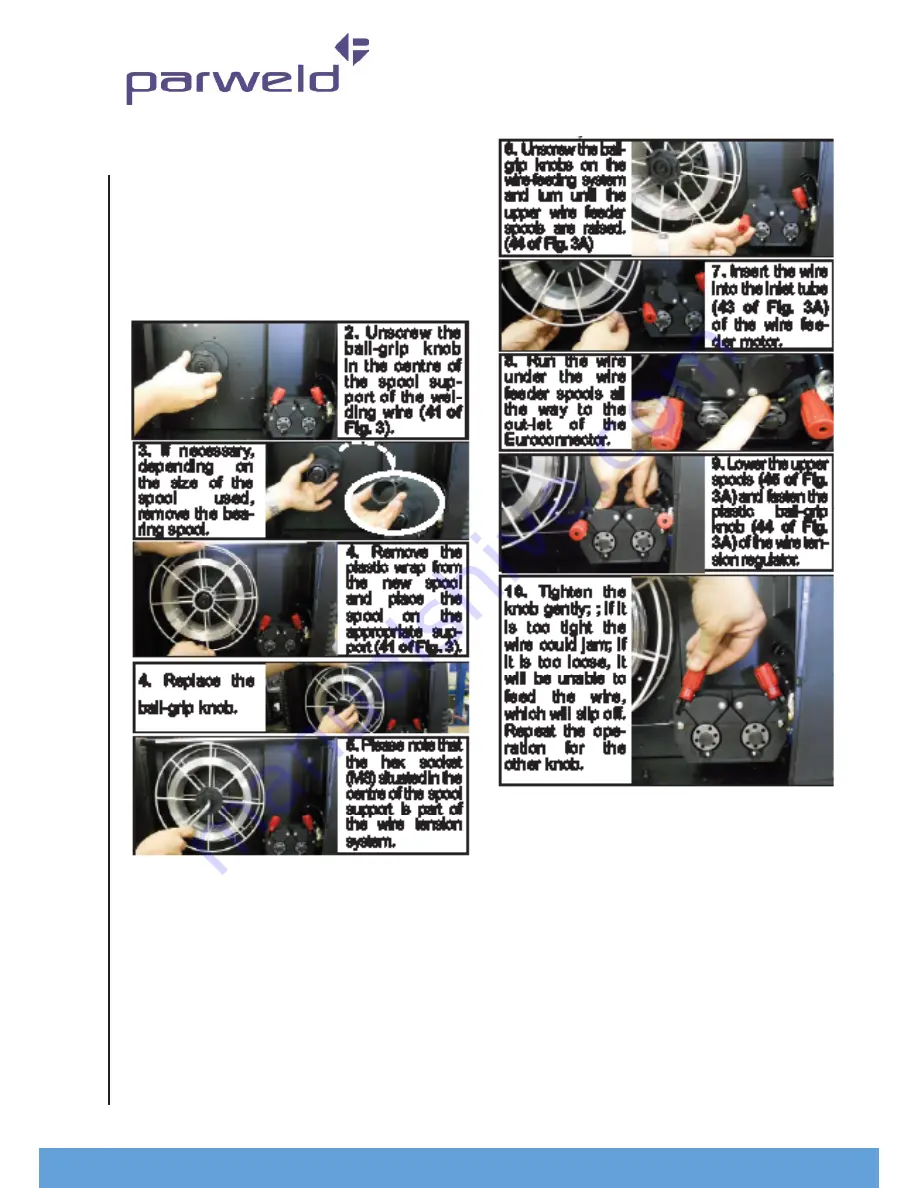

carefully, in the order described below.

Warning: before inserting the wire, always

remove the gas nozzle (Fig. 4A) and the wire

feeder tip (Fig. 4B) from the welding torch.

1. Disconnect the cable from the power supply

(32 of Fig. 2).

Tighten or loosen the hex socket to set the correct

tension: tightening too much can cause

excessive tension that could prevent the spool

from turning correctly. On the other hand, if the

tension is too loose, the welding wire could

accidentally unwind.

Caution: before proceeding with the next step, make sure

the torch cable (Fig. 4) is well extended and that the welding

wire does not have any bends or burrs. Failure to follow

these precautions could damage the wire-feeding tube

inside the torch. Once the wire has been threaded through

the torch, attach the wire-feeder tip and the gas nozzle.

N.B. When changing the diameter of the wire, make sure

that the correct cable of the wire-feeder spool is facing

towards the inside of the machine. To do so, ensure that

the diameter and type of wire is legible (facing towards the

outside of the machine) Remember that the spools with a

‘V’ cable are suitable for feeding iron and steel wire. The

spools with a ‘U’ are suitable for aluminium wire.

4. MIG/MAG WELDING To choose this welding

mode use switch 10, select MIG and press confirm.

9

Содержание DP323C

Страница 1: ...ISSUE 2 User Manual DP323C...

Страница 3: ...CONTENTS 2...

Страница 4: ...www parweld com 3...

Страница 5: ...www parweld com 4...

Страница 6: ...www parweld com 5...

Страница 9: ...www parweld com 8 3 LOADING THE WELDING WIRE To load the welding wire follow these instructions...

Страница 24: ...www parweld com 23...

Страница 26: ...www parweld com 25...

Страница 27: ...www parweld com 26 Spare Parts 26...