www.parweld.com

2. Move the torch with a continuous movement,

using a push, not pull, motion. This will guarantee the

gaseous shield of the arc.

3. Avoid welding in high winds. If the wind is too strong

it could carry the gas away from the welding pool,

creating a porous (weak) weld.

4. Keep the wire clean: never use rusty wire.

5. Make sure the torch cable is free of dents or coils,

which could compromise the correct movement of the

wire.

6. When changing the wire spool, always clean the

wire feed tube with compressed air

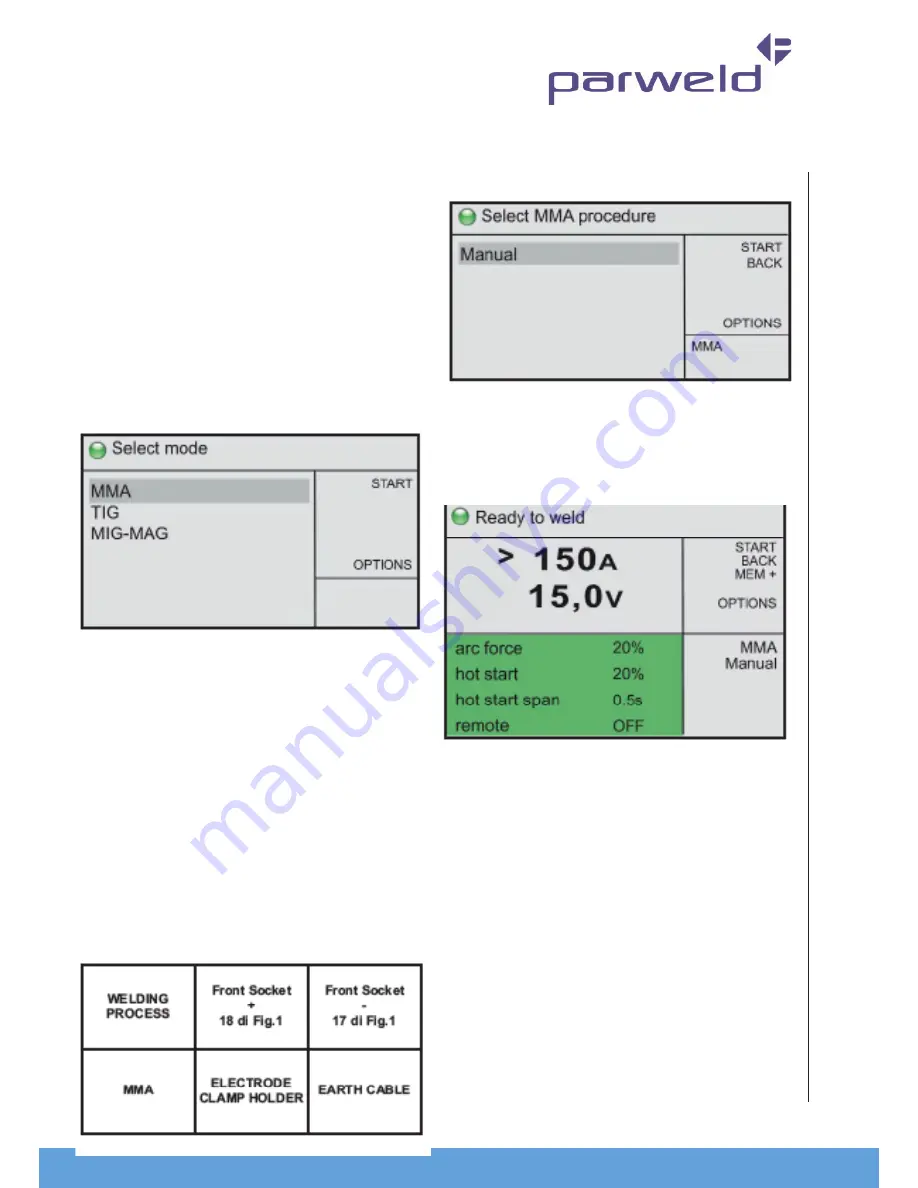

9. MMA WELDING

To select this welding mode, use

switch 10, select MMA and press confirm.

Electric arc welding with a covered MMA (Metal

Manual Arc) electrode or SMAW (Shielded Metal Arc

Welding) is a manual welding procedure that takes

advantage of the heat generated by the electric arc,

which strikes between a covered earthed electrode

and the workpiece. This procedure allows for the

creation of joints in any position, in the workshop,

outdoors, in confined areas or places that are difficult

to access.

With the DP403SW and DP503SW it is possible to

weld any type of electrode and diameter. The spark

of the arc occurs by placing the electrode close to the

workpiece.

The correct connection of the electrode clamp holder

and the earth cable can be seen in the table below:

Always make sure that the earth and the electrode

clamp holder are kept far apart.

9.1 MMA WELDING Manual

This mode can be

accessed using switch 10. Selecting this option will

take you to the welding screen:

Switch 9 in fig. 1 adjusts the welding current (very thick

workpieces require a higher current).

Furthermore, switch 10 adjusts the parameters shown

in the figure below:

Arc Force: This sets the current increase ratio in

relation to the welding current, that the welder can

force, in order to keep the arc appropriately ignited in

any position.

Hot Start: This sets the current increase ratio in

relation to the welding current, that the welder can

force when the arc is ignited, to improve the quality of

the same.

Hot start span: This sets the time period when the jot

start current is forced.

Remote: This switches the remote control (which

connects to socket 13 of fig.1) of the current intensity

ON or OFF.

16

Содержание DP323C

Страница 1: ...ISSUE 2 User Manual DP323C...

Страница 3: ...CONTENTS 2...

Страница 4: ...www parweld com 3...

Страница 5: ...www parweld com 4...

Страница 6: ...www parweld com 5...

Страница 9: ...www parweld com 8 3 LOADING THE WELDING WIRE To load the welding wire follow these instructions...

Страница 24: ...www parweld com 23...

Страница 26: ...www parweld com 25...

Страница 27: ...www parweld com 26 Spare Parts 26...