88

Gemini GV Hardware Installation Guide

Installation Guidelines

Gemini products are made available under “Restricted Distribution” for use in the

“Second Environment” as described in EN 61800-3: 1996, page 9.

Cabinet Mounting

For Electromagnetic Compatibility, cabinet mounting is not required. However,

Gemini drives have high voltage terminals—for safety purposes, the drive must

not be user accessible during normal operation.

Drive Mounting

The Gemini drive is designed to be mounted to an earthed metal panel. For EMC

performance, mount the mains filter to the same panel, as close to the drive as

possible. See the EMC Installation drawing at the end of this appendix.

Cable Routing

Route high power cables (motor and mains) at right angles to low power cables

(communications and inputs/outputs). Never route high and low power cables

parallel to each other.

Cable Shielding

All cables must maintain high integrity 360 degree shielding. Compumotor CE

cables are fully shielded and provide the required screening. When you install

limit switches and other inputs/outputs, you must observe proper noise immunity

standards. See the EMC Installation drawing at the end of this appendix.

Ferrite Absorbers

Some installations may require that you take additional EMC measures. To further

increase product immunity and reduce product emissions, you may add clip-on

ferrite absorbers to all cables. Compumotor recommends a ferrite with at least

200 ohm impedance at 100 MHz, such as:

Steward Ferrite

part number 28A2024

Fair-Rite

part number 0443164151

(These ferrites are available from Compumotor, part number 47-015956-01)

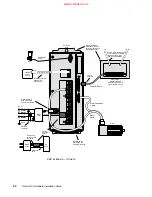

Enclosure Mounting the Gemini Drive

The enclosure must be properly earthed and paint must be removed from drive

mounting and RF earth bonding locations. Proper shield termination of all cables

entering and exiting the enclosure is required. The motor shield (braid) must be

fastened to the drive using the included saddle clamp or R-Clamp. The shield must

not make contact with other conductors, as this will cause common mode drive

generated PWM current to flow where not expected. The shields of all other cables

that enter or exit the enclosure must be RF bonded to the enclosure entrance point

via R-Clamp, bulkhead clamshell clamp, or other 360

°

bonding technique. This

ensures that no stray noise will enter or exit the enclosure. The next drawing

illustrates 360

°

bonding techniques.

www.comoso.com