Appendix D – EMC Installation Guidelines

65

motor cable is not within earthed conduit the entire length

of travel, the standard motor cable should not be used.

At the drive end of the motor cable, fit a ferrite absorber

over the cable before wiring to the motor connector (it

may be necessary to remove the existing connector).

Locate the absorber as close as possible to the connector

using heat-shrink sleeving.

For motors with exposed cabling (not within earthed

conduit), follow the guidelines below:

• Removable Cabling: Remove the motor cable from

the standard motor, and replace with a suitable cable

described below, see Motor Cables.

• Permanent Cabling: Cut off cable in excess of

approximately 4 inches (10 cm). Configure the motor

for series or parallel operation and attach a suitable

braided screen cable to the motor, see Motor Cables

below.

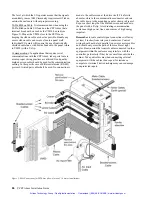

Termination of the braid shield at the motor must be made

using a 360° bond to the motor body, and this may be

achieved by using a suitable clamp. Many stepper motors

are designed to accommodate an appropriate terminal

gland which can be used for this purpose. If this is not the

case, P-clip the braid to the rear end bell of the motor

housing, as shown in Figure 4. This will not only provide a

good high-frequency bond, but strain relief as well.

At the drive end, run the motor cable down to the

mounting panel, expose a short length of braiding and

anchor to the panel with a P-clip. The ZETA Series

require a safety earth connection to the motor (see green

and yellow striped wire in Figure 4) — take this from the

stud or bus bar. Run the safety earth lead alongside the

motor lead. Note that the motor cable should be kept away

from I/O cables carrying control signals.

Motor Cables

For 10 foot (replacement) cable lengths, use 4-core 1mm

2

(AWG 18) (SWG 20) braided screen cable for the motor

connections on the ZETA6xxx. At the drive end, fit a

ferrite absorber over the cable before wiring to the motor

connector. Locate the absorber as close as possible to the

connector using heat-shrink sleeving (use AWG 16 cable

for motors above 10 amperes).

All after-market motor connections must be made using a

high quality braided-screen cable. Cables using a

metallized plastic foil for an earth screen are unsuitable

and provide very little screening. Terminating to the

screen in a mechanically stable manner is difficult because

the screen itself is comparatively fragile — bending it in a

tight radius can seriously affect the screening performance.

There must be no break in the 360° coverage that the

screen provides around the cable conductors. If a

connector must be used it should retain the 360° coverage,

possibly by the use of an additional metallic casing where

it passes through the bulkhead of the enclosure. The cable

screen must not be connected to the cabinet at the point of

entry. Its function is to return high-frequency chopping

current back to the drive or controller. This may require

mounting the connector on a sub-panel insulated from the

main cabinet, or using a connector having an internal

screen which is insulated from the connector housing.

Within the cabinet itself, all the motor cables should lie in

the same trunking as far as possible. They must be kept

separate from any low-level control signal cables. This

applies particularly where the control cables are unscreened

and run close to the drive or other sources of electrical noise.

Motor Feedback Cables

Feedback devices such as encoders, tachometers and Hall

effect sensors also require the use of high-quality braided

screen cable. If it is necessary to replace the standard

feedback cable, select a braided screen cable that matches

the gage of the devices original cable and attach as close

to the transducer as possible. Avoid complex and bulky

connections that can cause degradation in feedback signal

quality. If possible, use in-line cable splicing techniques,

and cover the splice point with heat-shrink tubing. Remove

a section of the braided shield cable’s insulation to expose

the braid, and tie the braid to earth using the same P-clip

360° bond as shown in Figure 2. Differential signals

should use twisted pair cable to minimize magnetic

coupling. At the receiving end, fit a ferrite absorber over

the feedback cable before wiring the connector, then P-

clip the braid to a suitable ground (metal back-plane of

drive mounting panel, or earth point of device that

receives the feedback)— see Figure 3.

Step Motors

It is preferable to use motors with screw terminations

whenever possible. If flying-lead motors are used, it is

important that the unscreened leads are converted into a

braided-screen cable within 4 inches (10cm) of the motor

body. A separate terminal box may be used for this

purpose but the braided cable screen must be properly

strapped to the motor body, as shown in Figure 4. Motors

fitted with terminal boxes also allow local selection of

series or parallel connection, reducing the cost of the cable

running back to the drive.

Control Signal Connections

High-quality braided screen cable should be used for

control connections. In the case of the ZETA6xxx, which

has differential step-direction inputs, it is preferable to use

a cable with twisted pairs to minimize magnetic coupling.

No connection is made to the cable screen at the drive

itself. Fit a ferrite absorber close to the I/O connector and

run the cable down to the mounting panel as shown in

Figure 3. Expose a short length of the braided screen and

anchor to the panel with a P-clip.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com