For more information about the Low Voltage Directive (LVD), see 73/23/EEC

and 93/68/EEC, published by the European Economic Community (EEC).

Environmental Conditions

Pollution Degree: The ZETA6xxx is designed for

pollution degree 2.

Installation Category: The ZETA6xxx is designed for

installation category II.

Electrical

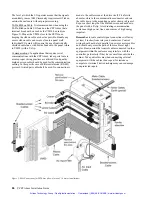

Connecting & Disconnecting Power Mains

The ZETA6xxx’s protective earth connection is provided

through its make-first/break-last earth terminal on the

power mains connector. You must reliably earth the

ZETA6xxx’s protective earth connection.

Using an Isolation Transformer

The ZETA6xxx’s mains voltage is limited to 120 VAC

(240VAC for ZETA6104-240) nominal. If your mains

voltage is higher, use an isolation transformer located

between the power mains and the ZETA6xxx. Your

isolation transformer should be insulated to ~2300V rms.

Do not interrupt the protective earth conductor between

the source mains and the isolation transformer’s

secondary. The core of the isolation transformer and the

drive’s protective conductor terminal must both be

connected to the mains protective earth conductor.

CAUTION — Do not use an autotransformer.

Adding Line Fuses

Line fuses need to be added to protect the transformer and

associated wiring. If the live wire cannot be readily

identified, fuse both phase conductors. The value of fuse

required is given by: (1.5 x VA)/(supply volts) [amps]

Fuse types should be anti-surge HBC.

WARNING —

Safety Ground (Earth Ground)

should never be fused.

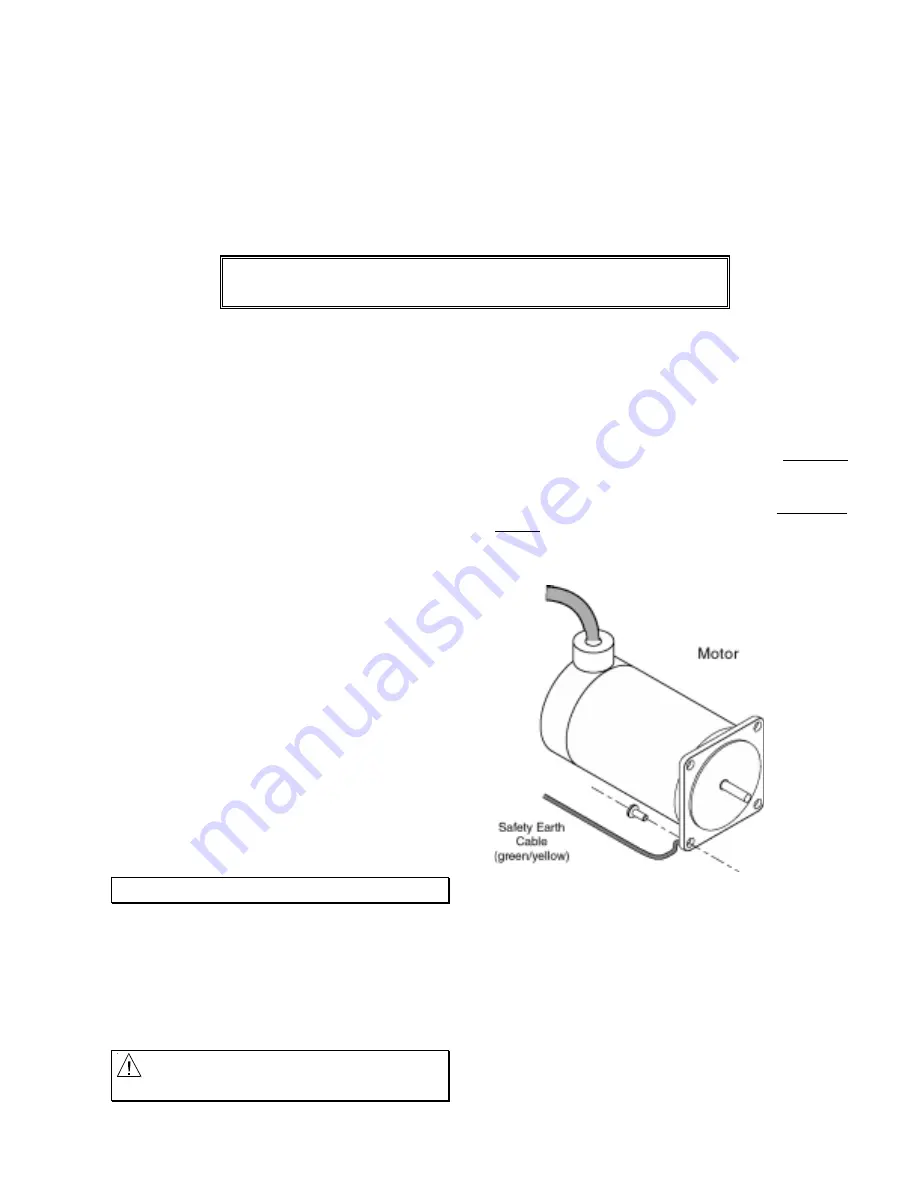

Providing a Protective Earth Connection for

Motors

You must provide a connection from the motor to a

reliable protective earth contact point. This connection

provides a protective earth for the motor, and is in addition

to the earth connection provided by the drain wire in the

motor’s power cable. The motor’s protective earth

connection is important for safety reasons, and must not be

omitted.

Make connections according to the diagram and

instructions below:

1. Use a spade lug in combination with a star washer and

mounting bolt to make good contact with the bare

metal surface of the motor’s mounting flange.

2. Use a green and yellow striped wire to make the

connection between the motor and earth. Wire gauge

must be no thinner than the current carrying wire in the

motor’s power cable.

3. Resistance between the motor and earth must be no

greater than 0.1

Ω

. Use thicker gauge wire if the

resistance is too high.

Appendix C

L V D I n s t a l l a t i o n I n s t r u c t i o n s

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com