5

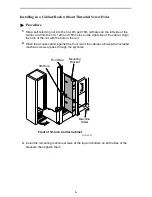

Installing in a Cabinet/Rack with Threaded Screw Holes

Procedure

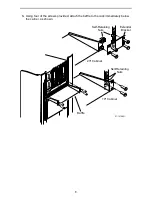

1. Use a screwdriver to install the screw loosely enough to allow the bracket keyhole to

drop under the screw head during installation. Use the 9th hole as shown on the left

side of the carrier. Use the 12th hole on the right side of the carrier.

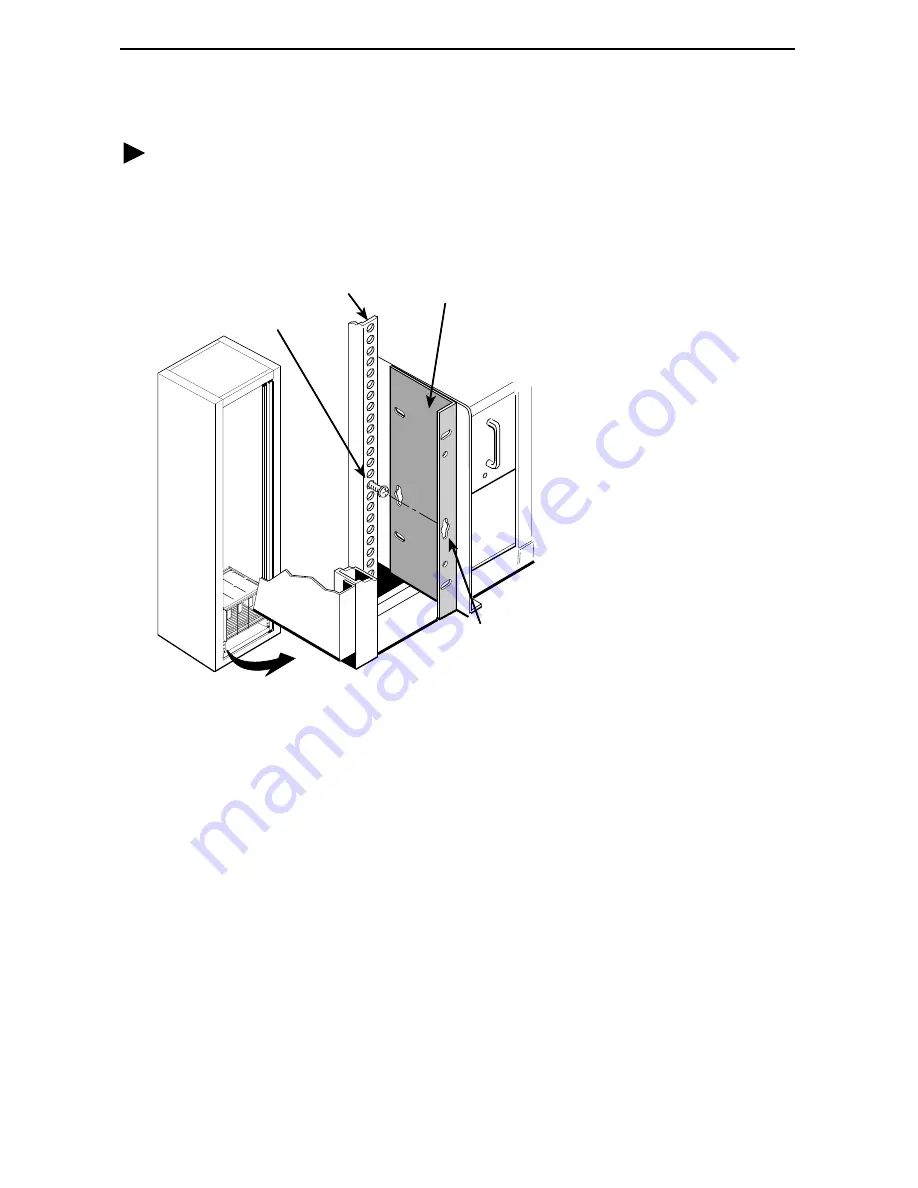

2. Place the access carrier against the front rail of the cabinet, allowing the installed

machine screws on each side to pass through the keyholes.

3. Lower the access carrier into place, allowing the keyholes to slide under the screw

heads. This positions and supports the access carrier correctly for installation of the

remaining machine screws.

4. Install the remaining machine screws at the top and bottom on each side of the

brackets and tighten them.

Front Rail

Mounting

Bracket

496-15131

Front of 19-Inch Carrier Cabinet

9th Hole

Keyhole