NOTE:

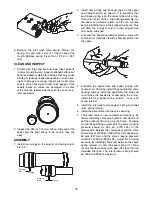

The close fitting piston backup ring (6) may

be depressed slightly to one side to lodge it in the

brake cylinder bore and temporarily hold the pres-

sure plate and springs in place while the brake cylin-

der is inverted and lowered over the motor adapter.

As an alternate, the motor adapter and brake plates

can be turned over and installed into the brake cylin-

der, holding the brake plates and spacer in place

through the center opening. Be careful to not pinch

your fingers between the spacer plate and the pres-

sure plate.

7. Apply petroleum jelly or an oil soluble grease to the

sealing surface of the brake cylinder and the piston

seal. Turn the brake cylinder over and lower it onto

the motor adapter, being careful not to damage the

piston seal or O-Ring on the adapter. Be careful the

O-Ring (13) does not fall out of place, and the oil

passages are aligned. The alternate assembly

method above could also be used.

8. Turn the entire assembly over and install the four

capscrews and lockwashers. After the capscrews

make contact with the motor adapter, evenly tighten

them one turn at a time until the motor adapter is

drawn tight against the brake cylinder, then torque to

the recommended value.

BRAKE CYLINDER PRESSURE TEST

1. Install a -6 ORB fitting into the brake release port on

the motor adapter. Connect a hand pump with an

accurate 0-2,000 psi (0-13,800 kPa) gauge and

shut-off valve to this fitting. Apply 1,000 psi (6,900

kPa) to the brake and close the shut-off valve. Let

the unit stand for five minutes. If there is any loss of

pressure, the brake cylinder should be disassem-

bled for inspection of the sealing surfaces, seal and

O-Ring. When the source of the pressure leak has

been determined and corrected, re-assemble the

brake cylinder and repeat the test.

2. WHILE PRESSURE IS APPLIED AND THE BRAKE

IS RELEASED, install the over-running clutch

assembly into the brake pack. Turn the clutch back

and forth to align the splines on all the friction discs.

Release the pressure on the brake cylinder and

remove the clutch assembly. The brake cylinder is

now complete and ready to be installed in the hoist.

26