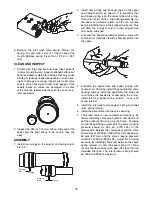

1. Thoroughly clean the machined surfaces of the cast

base (61). Make sure the tapped holes, end plate

and bottom mounting surfaces are free of paint and

rust. Place the base on a clean, sturdy work sur-

face.

2. If the drum bearing support (41) was removed from

the end plate, install it into the end plate with the

vent port near the top and the word “LEVEL” read-

ing correctly in a horizontal plane. Install the bearing

support/end plate sub-ssembly onto the base using

capscrews and washers (60 & 62). Evenly tighten

the capscrews to 180 lb.-ft. (244 N-m) torque. Lay

the base and end plate over such that the drum

bearing support faces up.

3. Install a new bearing into the drum if replacement is

necessary, making certain to press it against the

shoulder in the bottom of the bearing bore. Coat the

outside diameter of a new seal with a good grade of

sealant. Turn the spring side of the seal toward the

bearing, and press the seal into the seal bore, leav-

ing it flush with the surface of the drum bore.

4. Turn the drum over, and set it down on the bearing

support. Be careful not to damage the seal when

lowering the drum onto the bearing support.

5. Apply a light coat of oil-soluble grease to the pri-

mary sun gear thrust pad (102) then install it into the

recess in the primary planet carrier(s).

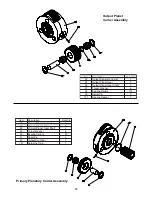

6. Install the primary planetary carrier assembly (3)

into the drum. Rotate the carrier as you mesh the

planet gears with the ring gear machined in the

drum.

7. Apply a light coat of oil-soluble grease onto the

thrust washer (66) and install the thrust washer onto

the primary planet carrier. Install the input sun gear

(55) into the primary planetary carrier.

8. Install the output planetary carrier assembly (4) into

the drum. Rotate the carrier slowly as you mesh the

planet gears with the ring gear.

9. Install a new bearing (64) into the drum closure (56)

if replacement is necessary, making certain to press

it against the shoulder in the bottom of the bearing

bore. Lightly coat the outside diameter of a new

drum seal (70) with non-hardening sealant. Install

the seal into the closure with the garter spring

toward the bearing. Press the seal into the bore until

it is even with the outside surface of the closure.

Install a new o-ring (68) into the groove in the out-

side diameter of the closure. Lubricate the outside

diameter of the closure with multi-purpose grease

and install the closure into the drum. Push the clo-

sure into the drum until it bottoms against a shoul-

der machined into the drum. If the closure bottoms

on the output planetary carrier before it bottoms in

the drum, you may have installed the primary thrust

pad upside down and the gear train must be

removed to check this condition. Do not proceed

until this is resolved.

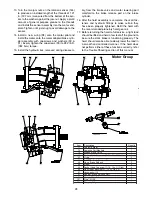

10. Place the motor side end-plate (40) onto the drum

and loosely install the ten capscrews and washers

(60 &62) that secure the end-plate to the base. Do

not fully tighten the capscrews at this time.

11. Use multi-purpose grease to lubricate the bearing

journal, seal journal and mounting flange surfaces

of the brake cylinder housing (2). Carefully install

the brake cylinder into the drum closure. It may be

necessary to slightly rotate the brake housing to

engage the splines of the housing with the output

planet carrier.

12. Secure the brake cylinder to the end-plate with eight

capscrews and washers (51 & 52). Tighten the cap-

screws to 80 lb.-ft. (109 N-m) torque. Tighten the

fasteners in a cross pattern to maintain even clamp

load. Install the over-running brake clutch assembly

(1) into the brake cylinder assembly. If the splines of

the outer race and the brake discs do not line up,

install a hydraulic adapter into the brake release

port and connect a hand pump to the adapter. Apply

approximately 600 PSI (4150 kPa) to release the

static brake. When released, rotate the brake clutch

assembly back-and-forth to align the discs. The

brake clutch assembly must be installed with the

long shoulder of the outer race toward the motor

and the internal retaining ring inside the inner race

must be offset toward the hoist drum to make room

for the motor shaft. The internal retaining ring

should seat against the input sun gear when cor-

rectly installed. Finish tightening the end plate to

base capscrews, installed in step 10 above, to 160

lb.-ft. (217 N-m) torque.

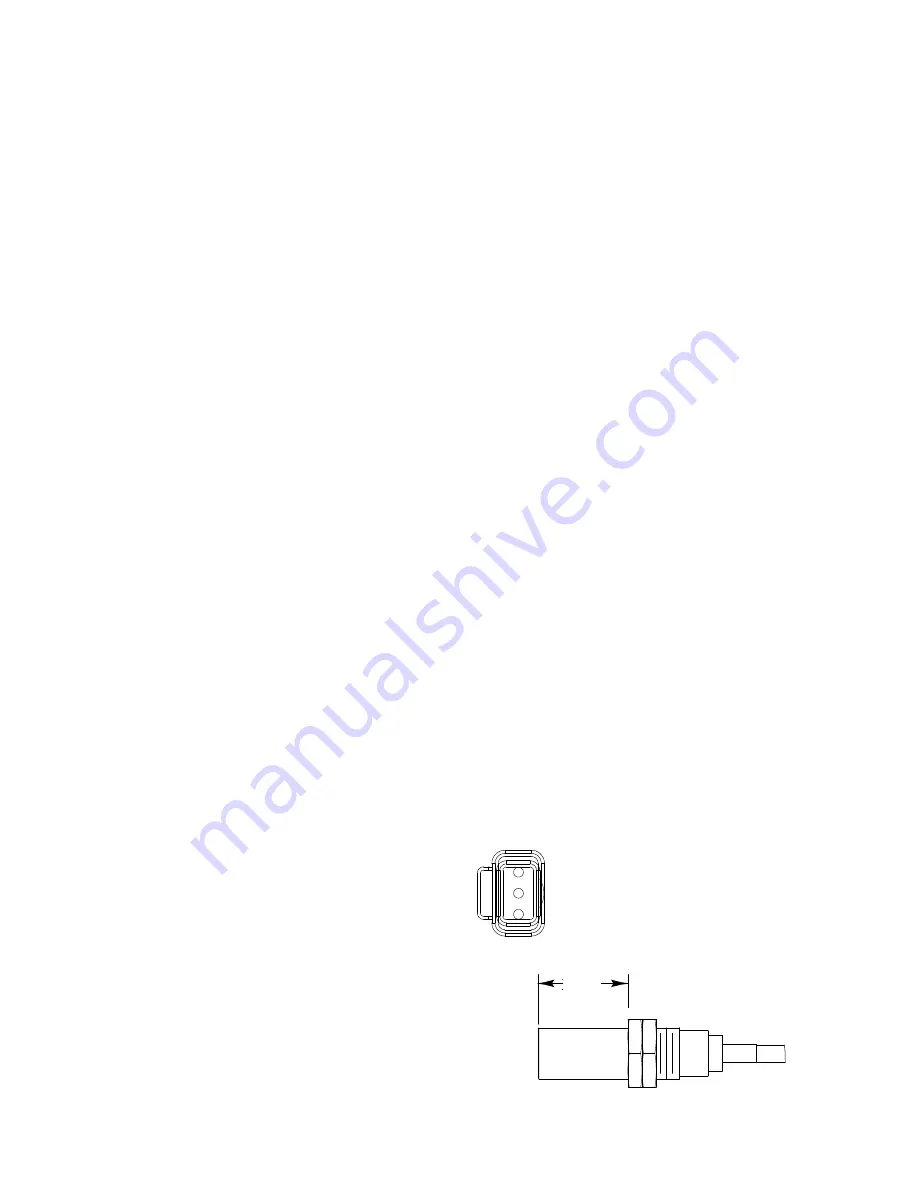

HOIST ASSEMBLY

(Refer to illustration on page 8)

Adjust sensor nut to 1.21 in. (30.7 mm)

before installation into motor end plate

27

Sensor Connector

3

2 (-)

1 (+)

Pin 3 = Ground (Blue)

Pin 2 = Output (Black) (-)

Pin 1 = Supply (Brown) (+)

1.21