1. Remove the wire rope from the drum and wind onto

a cable reel as recommended by the wire rope man-

ufacturer. Power wash the hoist and all motor piping

to remove contamination that might enter open hose

and motor ports. Drain the gear oil from the hoist as

described in the Preventive Maintenance section of

this manual.

2. Remove the cable guard roller and cable tension

roller group. Stand the hoist up on the drum bearing

support end with the motor end up. Secure the hoist

in this position so that it does not fall over and cause

property damage or personal injury.

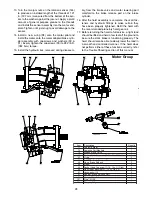

3. Tag and remove the hydraulic hoses that connect

the brake valve and motor manifold to the brake

release port.

4. Remove the four capscrews and lockwashers

securing the motor and lift the motor off the hoist.

Cover the motor ports to prevent contamination.

Remove the brake clutch assembly from the brake

cylinder. Disassembly of the brake clutch assembly

will be discussed in the “Brake Clutch Service” sec-

tion of this manual.

5. Remove the eight capscrews that secure the brake

cylinder to the motor side plate. Lift the brake cylin-

der out of the hoist and place on a clean work sur-

face. Disassembly of the brake cylinder will be dis-

cussed in the “Brake Cylinder Service “section of

this manual

.

6. Loosen the jam nut then remove the drum rotation

sensor from the motor side plate to prevent damage

to the sensor. Remove the ten capscrews that

secure the motor side plate to the base and lift the

side plate off the hoist drum.

7. Install two

½

in. NC lifting eyes into the tapped holes

in the drum closure and lift the closure out of the

drum.

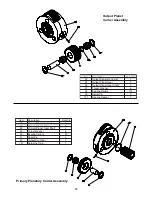

8. Remove the output planetary carrier assembly from

the drum.

9. Grasp the input sun gear shaft and lift the input

planetary carrier assembly from the drum.

10. Lift the cable drum off the drum bearing support and

endplate assembly.

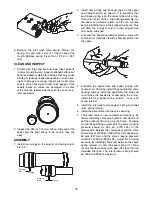

11. Thoroughly clean and inspect all components at this

time.

a. The drum bearings should roll freely and smooth-

ly. If they sound rough, clean again in solvent,

blow dry and inspect once more. If they still

sound rough, replace them.

b. Inspect sealing and bearing surfaces on drum

bearing support and brake cylinder for damage

that may prevent long seal and bearing life. If

damaged, replace or repair the components as

required.

c. Inspect the ring gear teeth for nicks, pitting or

excessive wear. To check for wear, place a

straight edge along the teeth such that the

straight edge spans from an unworn area, over a

worn area and again is supported by an unworn

area. Place feeler gauges under the straight

edge to measure the depth of the wear. If a small

ridge has been pushed up at the edge of the

worn area, you must first file down the ridge with

a flat mill file that spans across the worn area as

described for the straight edge. Replace the ring

gear if the wear in the gear contact area is

greater than .015 in. (.38 mm) when compared to

the unworn area of the teeth.

d. Conduct Magnetic Particle Inspection (MPI) of

the planet gears to check for any small stress

cracks that may not be visible to the naked eye.

Discard the gears if ANY cracks are found.

DISASSEMBLY PROCEDURE

The GHP30 hoist weighs approximately 1435 lb. (650

kg). Make certain lifting equipment has adequate

capacity. Using undersized or poorly maintained lift-

ing equipment may result in a dropped load, proper-

ty damage, injury or death.

CAUTION

The cable drum weighs approximately 350 lb. (160

kg). Make certain lifting equipment has adequate

capacity. Using undersized or poorly maintained lift-

ing equipment may result in a dropped load, proper-

ty damage or personal injury.

CAUTION

20