34

optics11life.com

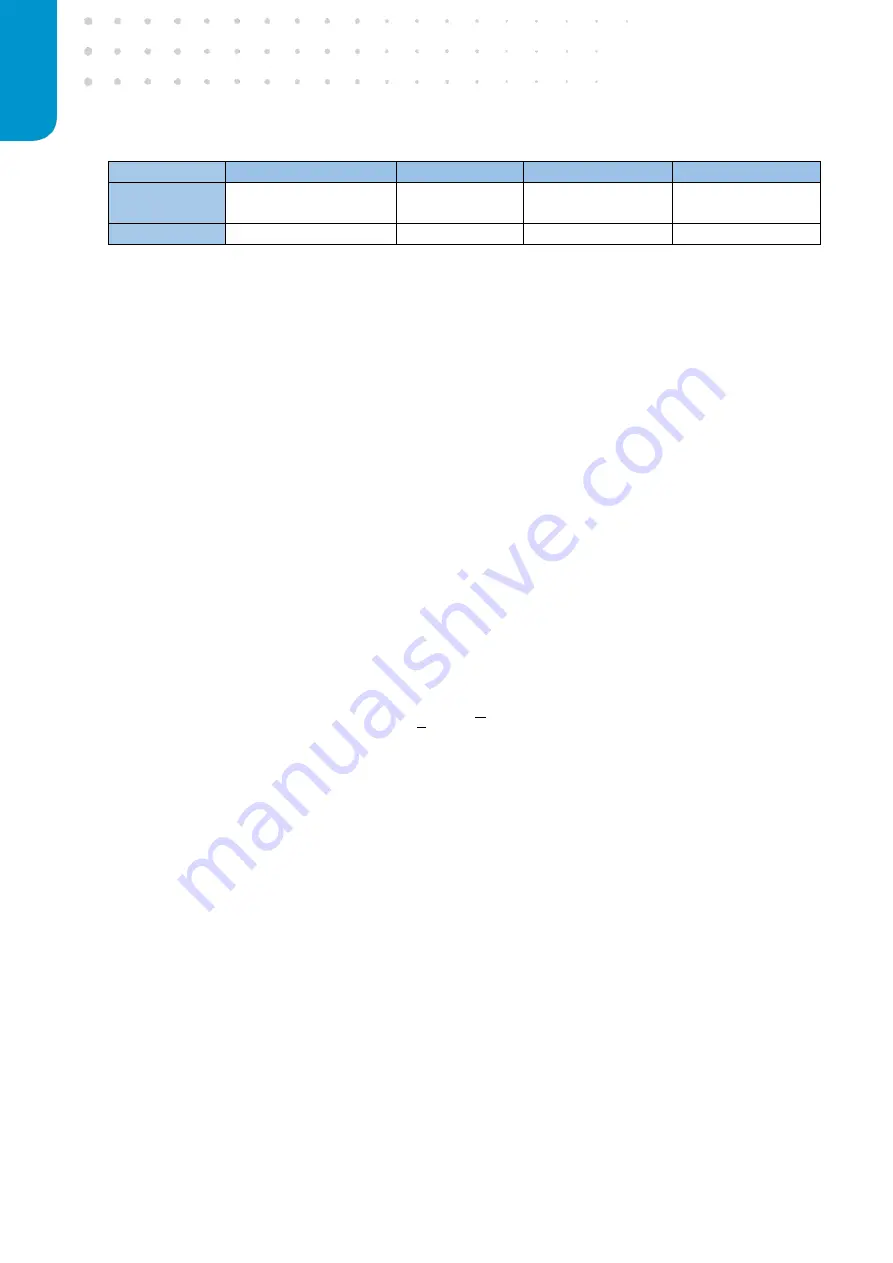

Table 3:

Comparison of the three modes of operation.

•

Displacement control operates in an open-loop, meaning that only piezo displacement is

controlled but not load or indentation-depth. The actual load and indentation-depth will depend

on the stiffness of the sample and the stiffness of the cantilever (

-a, c).

•

Load control operates in a closed-loop, meaning that the load and time it takes to reach this load

(load-speed) is selected by the user.

•

Indentation-depth control works in closed-loop as well, but this time indentation-depth and time

needed to reach it (indentation speed) are set by the user. The piezo is adjusted accordingly to

induce a selected load profile on the sample (

-b).

•

Peak load poking mode operates in an open-loop in which piezo speed is controlled to reach the

maximum load that is selected by the user after which the probe is retracted at high speed. This

mode can be considered as a mode between Displacement control and Load control modes.

Operating in an open-loop makes this mode very fast and well suited for single cells in

combination with Hertz model fitting.

During all three modes of operation, the instrument is recording piezo movement (blue) and cantilever

bending (green) shown in

-a.

Indentation depth is calculated by subtracting cantilever bending

from piezo movement while in contact with the sample. The load is calculated by multiplying cantilever

bending with the spring constant of the cantilever.

The contact point with the sample (0 point in

indentation graph)

and effective Young’s modulus

is determined from the Hertz model to fit over the

initial load-indentation curve (

-e, red line):

𝐹 =

4

3

𝐸

𝑒𝑓𝑓

√𝑅 ∙ ℎ

3/2

𝐸 = 𝐸

𝑒𝑓𝑓

(1 − 𝜈

2

)

where

F

is load,

R

is the tip radius,

h

is indentation depth,

𝜈

is Poisson’s ratio,

𝐸

𝑒𝑓𝑓

is effective Young’s

modulus and

E

is

Young’s modulus which can be estimated with Poisson’s ratio is known.

Thus, if the

fitting has failed, the wrong contact point will be drawn in the graph. This can be corrected in DataViewer.

Changes to fitting in the main software can be done in

the “

Options

”

menu (

-b). Keep in mind

that this fit is just a preliminary one and one can change fitting parameters and contact mechanics models

in DataViewer.

D-mode

P-mode

I-mode

PLP-mode

Controlled

parameter

Piezo displacement

Load

Indentation depth

Piezo speed & max

load

Sample Circuit

Open-loop

Closed-loop

Closed-loop

Open-loop

Содержание PAVONE

Страница 1: ...PAVONE USER MANUAL ...

Страница 50: ...50 optics11life com Figure 42 Different stages of wellplate calibration process a b c d ...

Страница 64: ......