Open

Vertical

Electric

22

www.nuvair.com

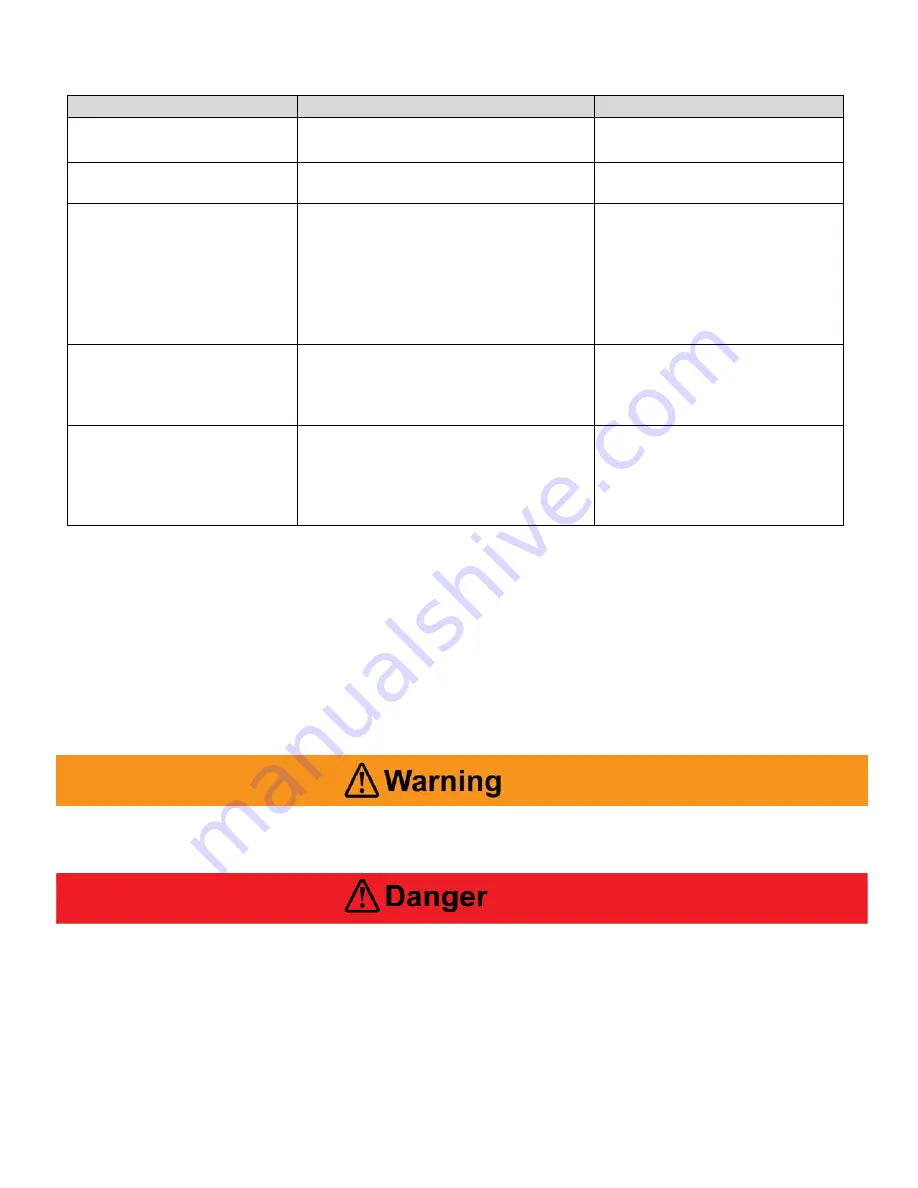

14.0 Troubleshooting

Problem

Cause

Solution

-The electric motor

does not start

Phase missing

Check fuses or capacitor

-Rotation speed and flow

rate decrease

Motor power too low

The belt slips

Check the motor and the line

Restore drive belt tension

-The flow rate diminishes

without rpm decreasing

Valves not working

Final stage piston worn

Fittings loose / leaking seals

Intake filter clogged

Intake extension kinked

Piston or piston rings worn

Contact technical support

Contact technical support

Check for leaks with soapy

water and eliminate them

Replace filter

Straighten, use stiffer pipe

Contact technical support

-Air smells of oil

Cartridge filter exhausted

Piston rings worn

Condensate not being drained

Replace filter

Contact technical assistance

Check Auto Drains & manually

drain more often

-Compressor overheats

Direction of rotation wrong

Cooling tubes dirty

Incomplete valve closure

(causing overload of another stage)

Poor Ventilation

Check direction of rotation

Clean Cooling Tubes

Contact technical support

Contact technical support

15.0 Checking and Changing the Lubricating Oil (and Filter on Tropical Plus)

During the compressor’s initial break-in period the original oil (and filter) must be changed after the

first 50 hours

. After the initial change, the oil (and filter) must be changed every 250 hours of use or

annually, whichever comes first.

HP Compressor Lubricant: Only use lubricants rated for use with Breathing Air such as Nuvair 455

TM

Synthetic Food Grade Lubricant or Nuvair 751.

Never mix Compressor Lubricants.

Nuvair

Compressors are shipped with Nuvair 455 Synthetic Food Grade Lubricant or Nuvair 751

in the

compressor.

Use only the specified Nuvair Lubricants in this system. The use of incompatible lubricants

presents a risk of fire and/or explosion, and may result in system damage. This can lead to

severe personal injury and death.

Do not carry out these tasks if the compressor has only just shut down; wait for the

compressor to cool. Pressure must be drained before opening LP Fill Plug.

Any oil spilt during the oil/filter change could cause personnel to slip; wear protective

garments and anti-slip footwear and remove traces of oil immediately.

Both oil and filter are classified as special wastes and must therefore be disposed of in

compliance with the anti-pollution laws in force.

All maintenance work must be carried out with the compressor OFF and the power supply

lead unplugged from the main socket.

Содержание 8060

Страница 1: ...User Manual Open Vertical Electric MCH13 16 Rev 05 20 www nuvair com ...

Страница 2: ...Open Vertical Electric 2 www nuvair com ...

Страница 35: ...Open Vertical Electric 35 www nuvair com Service Log Date Technician Name Service Performed Machine Hours ...

Страница 37: ...Open Vertical Electric 37 www nuvair com Notes ...

Страница 38: ......

Страница 39: ...Open Vertical Electric 39 www nuvair com ...