Page 24 of 31

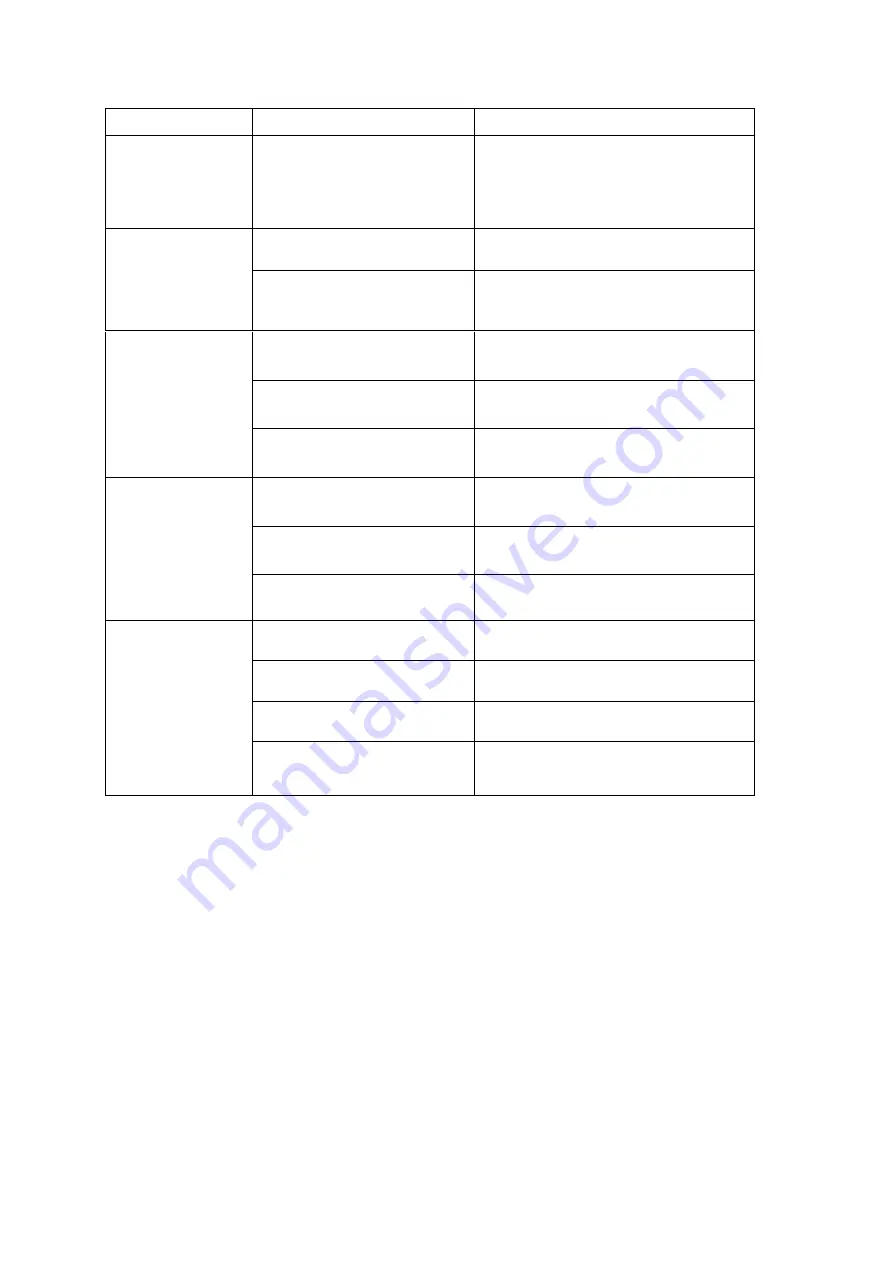

Failure

Possible Cause

Corrective Action

4. The limb is too long.

4. If the limb diameter for the side chute

is 2"-3" and the length is over 31" long,

help the limb feeding by slightly holding

to keep the rotate speed.

Engine runs but no

material is

discharged

1. Discharge chute clogged.

1. Clean out debris.

2. Engine not running at full

speed.

2. Set throttle control to FAST if

equipped.

Chipping action

slow, or engine

stalling

1. Branch diameter is too thick.

1. Do not process branches over 3"

diameter.

2. Throttle set is too slow.

2. Adjust throttle to increase engine

speed.

3. Tree limbs are extremely hard

or dried out.

3. Material is not suitable for chipping.

Unusual noise or

vibration when

chipping material

1. Rotor overloaded with

material.

1. Allow unit to clear itself before adding

more material to the hopper.

2. Hammers are broken, bent,

or loose.

2. Check assembly. Tighten or replace

as necessary.

3. Hammers frozen in place.

3. Check for obstructions and debris.

Repair or replace as necessary

Vacuum not working.

1. Hopper gate not closed.

1. Slide gate to closed position.

2. Cone cover not installed.

2. Allow material to dry.

3. Hose not attached properly.

3. Clear blockage or replace.

4. Engine is not running at full

RPM.

4. Set throttle control to FAST if

equipped.

REPAIR

Shredding Hammer Rotation and Replacement

The cutting edges of the shredding hammers may eventually wear out requiring rotation of the

hammer or replacement if all cutting edges have been dulled.

To rotate the shredding hammers:

1. Turn the engine off and wait for all moving parts to stop.

2. Disconnect the spark plug wire and secure it away from the spark plug.

3. Detach the rotor housing and hopper from the rotor plate. See Figure 9.

4. Note the assembly sequence of the hardware used to secure the hammers. Using an allen wrench,

remove the socket head cap screw (A) and related hardware. See Figure 10.

5. Inspect the hammers (D), spacer tubes (C, E), and hardware. If the spacer tube (E) shows signs of

wear, replace it. Inspect and flip, or replace the hammers (D).

6. Reassemble the hammers, spacers, washers, and cap screws. Torque the socket head cap screws

(A) back tightly.

7. Repeat for all the hammers.

Содержание Powerhorse 63388

Страница 9: ...Page 9 of 31 Safety Labels...

Страница 10: ...Page 10 of 31...

Страница 26: ...Page 26 of 31 Parts Diagram...

Страница 27: ...Page 27 of 31...