Use and Maintenance Manual model “H14 V SHAPE”

4

ENGLISH

1

INTRODUCTION

The product

by Nobis

was designed and manufactured

in compliance with the reference standards for the

manufacturing products (EN13240 wood stoves,

EN14785 pellet appliances, EN13229 fireplaces/

inserts for wood, EN12815 wood stoves), with

high quality materials. The products also comply

with the essential requirements of the Directive 2006/95/

EC

(Low Voltage) and the Directive 2004/108/EC

(Electromagnetic Compatibility).

The printing, translation and reproduction,

even partial, of this manual is intended

as binding by the manufacturer's authorisation and

the content of working logic and explanatory

figures is considered not be be disclosed.

Always consult the authorised technicians if in

doubt and/or confused by operation of the

the product.

The manufacturer reserves the right to make changes to

specifications and technical and/or working features of

the product at any time without prior warning.

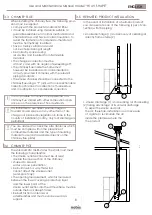

1.1 SYMBOLS

The following manual contains symbols which high-

light the importance of particular descriptions or con-

cepts;

INFORMATION: Compliance with the specifications

guarantees correct operation of the product.

ATTENTION: Symbol used to identify

particularly important information

DANGER: The presence of this symbol

indicates utmost attention is required, to guarantee

user and product safety.

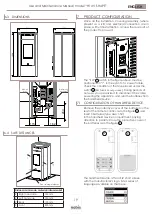

1.2 PLANNED USE

The product in this manual, is a

fireplace for domestic heating,

feed by automatic loading and exclusively with wood

pellets.

The product was designed and manufactured to work in

safety if the following conditions occur:

• installation by specialist staff

according to the specific reference standards;

• use within the limits declared on the product

data sheet and in this manual;

• compliance with technical procedures described in the

manual;

• carrying out routine maintenance within the times

and methods indicated in this manual;

• prompt execution of extraordinary

maintenance if necessary

(malfunctioning);

• activity and maintenance of safety devices

(do not remove or bypass this devices).

1.3 IMPROPER USE

The product must be intended for the use for which it

was expressly designed; for any other use, the manu-

facturer cannot

be held in any way liable for damage caused to

people, animals or property.

Improper use is intended as:

• use of the product as an incinerator;

• use of the product with fuel other than

wood pellets with a diameter of 6 mm;

• use of the product with liquid fuel;

• use of the product with the fire door open and/or

glass broken and/or ash pan removed and/or

pellet tank open.

Any other use of the appliance other than that

planned must be authorised in advance

in writing by the manufacturer.

Furthermore, the manufacturer cannot be held in

any way liable for errors in installation, adjustment or

maintenance of

the product.

1.4 IMPORTANCE OF THE MANUAL

The manual has the purpose of providing essential

rules for correct installation, use and maintenance of

the product.

PRESERVATION: Keep the manual in a place that is

easy and quick to find;

DETERIORATION OR LOSS: Consult the official site to

download the manual;

PRODUCT TRANSFER: In the event of sale between pri-

vate individuals of the product, the owner is obliged

to

deliver the product with the following manual.

1.5 GENERAL SAFETY WARNINGS

Non-compliance with the provisions of this manual can

cause damage to people, animals and property.

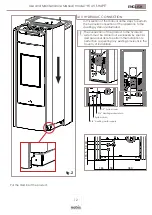

• Installation, testing of the system, functionality

testing and initial calibration of the

product must only be carried out by

qualified and authorised staff.

• The product must be connected to a single chimney

flue that guarantees the draught declared by the

manufacturer and which complies with the installa-

tion

standards outlined in the assembly location of the

product.

• The premises where the product is installed must be

adequately ventilated (air intake).

• Do not touch the hot surfaces without adequate

protective equipment, to avoid burns.

• When in operation, the external surfaces

reach high temperatures.

• It is forbidden to make changes to the product unless

expressly communicated in writing by the

manufacturer.

• In the event of fire in the chimney flue, contact

the Fire Brigade immediately.