11

7. Vacuuming (de-airing) process

•

When the clay reaches the appropriate consistency,

remove any clay that might be clogging the air inlet. If

clay covers the air inlets, the readings on the vacuum

gauge will increase, but the inside of the may not be

de-aired.

6. Checking the mixed state

•

Carry out mixing for a while and when the electric

current value of the motor becomes stable, check the

state of clay. If the clay is too hard, added water; if it

is too soft, add hard clay.

•

Make sure the nozzle cover is clean, then place it over

the nozzle.

• Close the vacuum’s pressure relief valve, then turn ON

the vacuum pump. The reading on the vacuum gauge

will gradually increase. The gauge should reach a

minimum of 0.09 Mpa.

•

Set the selector switch to MIX. Slowly set the speed

control to 6 to 8.

If the vacuum pressure suddenly increases,

the gap between the door, near the air inlet,

and the case might be clogged with clay.

Remove the clay in that gap. If this does not fix

the issue, there might be too much clay being

mixed. Decrease the amount of clay.

•

Mix clay with water and then continue the operation

of the vacuum pump and the screw for about three

minutes.

Clay becomes harder as it is de-aired.

Therefore, the mixed clay should be softer than

what is desired for use.

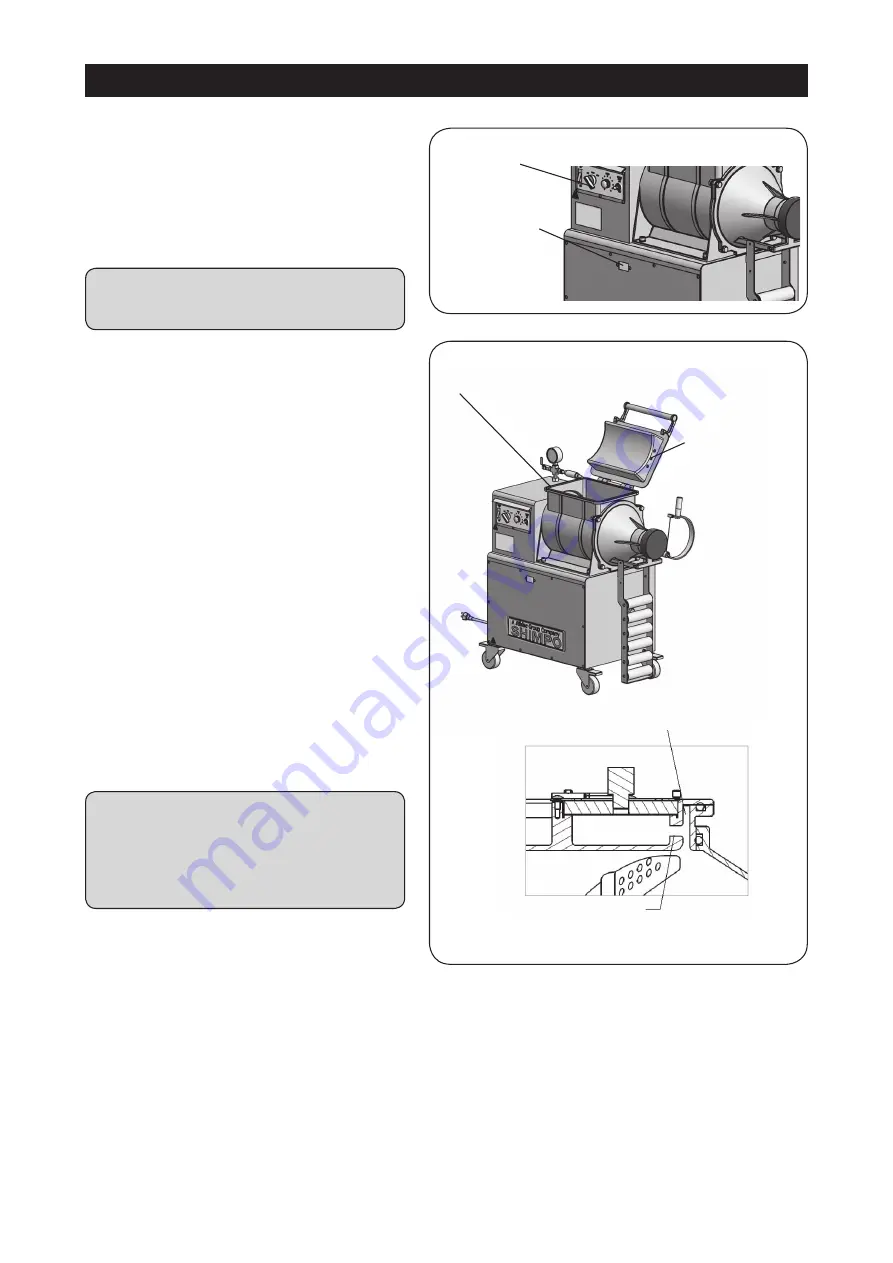

Clean both surfaces of the hopper cover and the case

(including the gasket).

Remove clay

between the

hopper cover and

the case and from

the air inlet.

Gap between hopper cover and case

Air inlet

If the gap between the hopper cover, near the air inlet, and

the case are clogged with clay, do de-airing will occur.

Note)

Set the selector

switch to STOP

Note)

Comfirm the

electric current

value showed in

the indicator

English

Operation procedure

Содержание NVS-07

Страница 2: ......

Страница 45: ...44 MEMO...

Страница 46: ...45 MEMO...

Страница 47: ...46...

Страница 48: ...1 Terada Kotari Nagaokakyo city Kyoto 617 0833 Japan Phone 81 75 958 3608 FAX 81 75 958 3647...