10

The auger screw automatically stops after 2 hours of

continuous running, to prevent the mixed clay from

generating too much heat.

When the auger screw is stopped by the timer, “END”

will appear in the indicator box. Should this occur,

return the selector switch back to “STOP” to restart

the operation.

3. Add water.

•

Add an appropriate amount of water.

•

If the amount of water is not enough, an overload may

occur, causing the auger screw to stop. If the amount

of water is too much, the clay will become too soft,

preventing the clay from being mixed and extruded.

If you do not know how much water to add, add

water in gradually while keeping note.

Do not operate the vacuum pump until the clay has the

proper amount of water. Powdered components may clog

the vacuum chamber if the vacuum is turned on too soon.

Add an appropriate amount of water.

4. Close the hopper cover.

•

Close the hopper cover. If there clay on either rim

surface of the case or hopper cover, wipe it off. both

surfaces must be clean to create a good seal.

Push down on the handle so the hopper cover can

properly lock into the case.

Push down on the handle so the hopper cover can properly

lock into the case.

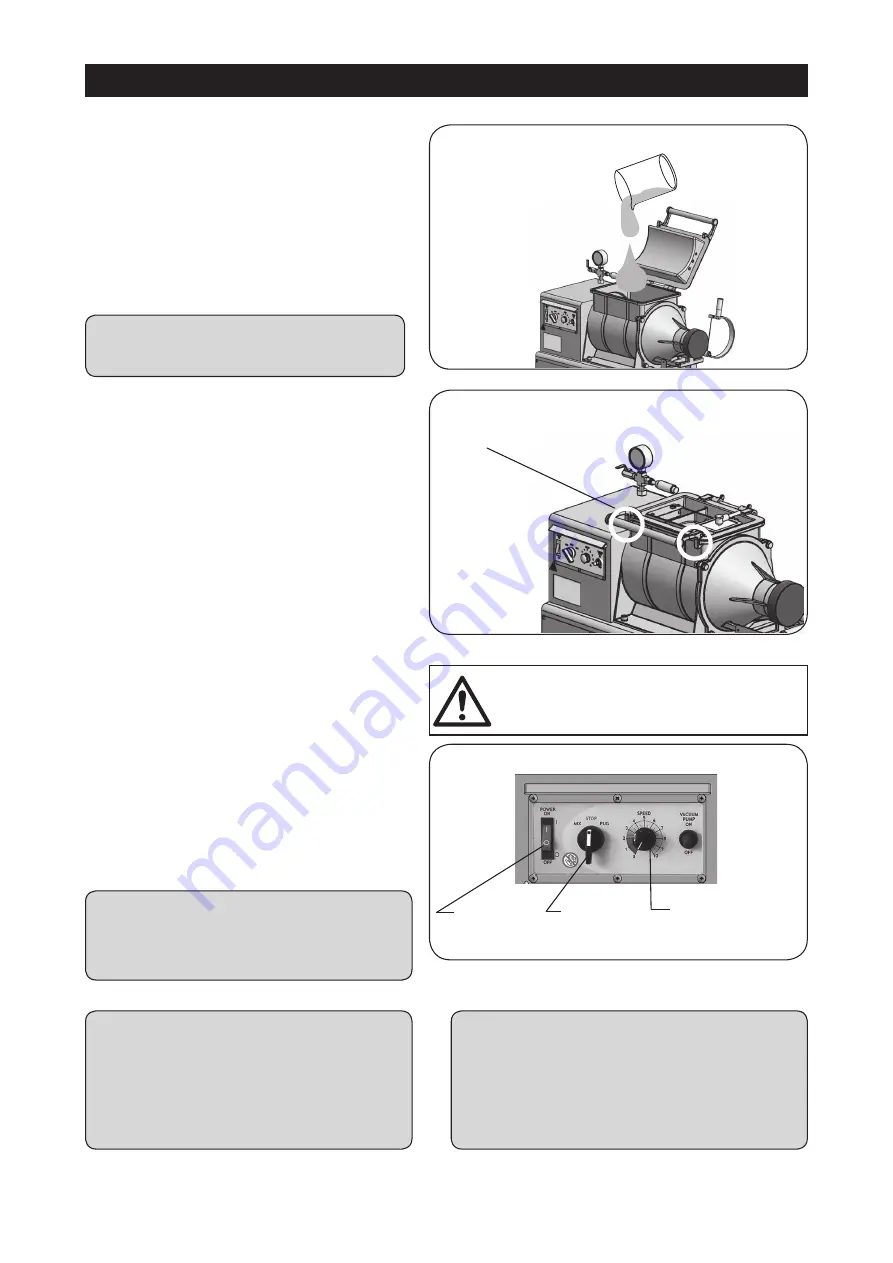

5. Mixing process

Turn ON the power switch and set the selector switch to

MIX. Slowly turn the screw speed control to select 6 to 8.

•

If there is not enough clay in the hopper, stop the

auger screw and add more clay and water. To stop the

auger, return the speed control to 0, set the selector to

STOP, then turn OFF the power switch.

•

Continue mixing for a while. If the electric current of

the motor exceeds 3.0 A, add water.

Do not access any switch with wet hand.

Warning

③

screw speed control

to select 6 to 8.

①

Turn ON the

power switch

Set the selector

switch to MIX

Do not set the speed control between 0 to 3.5.

If the auger screw is turns at too low a speed,

too much current will flow to the motor,

triggering the auger screw to stop.

Note)

The hopper cover has a limit switch sensor that

detects when the cover is open or closed. If too

much vibration is generated due to too large

of clay chunks, the limit switch sensor may be

triggered, causing the screw to stop.

If the limit switch sensor gets trigger too

frequently, the motor may shut down due to

overload.

Note)

Note)

Note)

English

Operation procedure

Содержание NVS-07

Страница 2: ......

Страница 45: ...44 MEMO...

Страница 46: ...45 MEMO...

Страница 47: ...46...

Страница 48: ...1 Terada Kotari Nagaokakyo city Kyoto 617 0833 Japan Phone 81 75 958 3608 FAX 81 75 958 3647...