2. When filling the brine system, mix the water with

antifreeze in the filling pump’s mixing vessel (2). The

mixture should have freezing protection down to

approx. -15°C.

3. Place the filling pump in a convenient location in the

vicinity of the GreenMaster-HP to optimise user-

friendliness.

4. Connect the power supply.

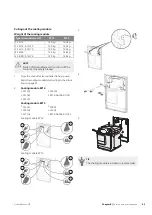

5. Connect hose (3) to filler connection (XL27).

6. Connect hose (1) to filler connection (XL28).

7. Ensure that shut-off valve (QM34) is in the closed

position, in the right-hand position.

8. Open the valves for the filler connections (XL27) and

(XL28).

9. Start the filling pump by pressing the filling pump’s

(4) start button.

10. Vent the system by performing the activities in step

6-8 in chapter Flushing with water and cleaning,

page 33.

11. Start filling slowly by closing filler connection (XL28).

Check that the pressure is gradually increasing using

pressure gauge (BP6).

12. When the pressure reaches 2.5 bar, close the valves

for the filler connections (XL27) and (XL28) simultan-

eously.

13. Turn off the filling pump.

14. Check whether there is any air left in the coil. Open

the heat exchanger’s (EP16) vent valve (QM21) to

remove any remaining air.

15. Leave the system in this state for 30 minutes.

16. Check that the pressure level has not dropped and

proceed to the next step. A pressure drop in the

system may be due to a leak in the system. If leaks

are discovered, they must be repaired. Then follow

the above steps again.

17. Open shut-off valve (QM34).

18. Disconnect the hoses (3) and (1).

NOTE

Carefully disconnect the hoses to prevent

flooding.

19. Go through the start guide for the GreenMaster-HP

(see page 37), keep checking the pressure level at

regular intervals for at least 8 hours.

NOTE

Make sure that the brine system does not con-

tain air before it is started up.. Failure to prop-

erly vent the system may result in damage to

components.

Filling and venting heating medium system

Filling

1. Open the filling valve (external, not included in the

product). Fill the climate system with water.

2. Open the vent valve (external, not included in the

product).

3. When the water that exits the venting valve is not

mixed with air, close the valve. After a while the

pressure starts to rise.

4. Close the filling valve when the correct pressure is

obtained.

Venting

1. Vent GreenMaster-HP via a vent valve (external, not

included in the product) and other climate systems

via their respective vent valves.

2. Keep topping up and venting until all air has been

removed and the pressure is correct.

NOTE

Make sure that the heating medium system

contains no air, before start-up. Failure to

properly vent the system may result in damage

to components.

Post adjustment and venting

Pump adjustment, automatic operation

Brine side

The brine pump must run at the correct speed for the

correct flow in the brine system. GreenMaster-HP has a

brine pump that can be automatically controlled in

standard mode. Certain functions and accessories may

require that they are run manually and the correct speed

must then be set, see section Pump adjustment, manual

operation.

The automatic control occurs when the compressor is

running and it sets the speed of the brine pump to obtain

the optimal temperature difference between the supply

and return lines. For passive cooling operation, for ex-

ample, the brine pump must run at a set speed, which

is set in menu 5.1.9

Heating medium side

To set the correct flow in the heating medium system,

the heating medium pump must run at the correct speed.

GreenMaster-HP has a heating medium pump that can

be automatically controlled in standard mode. Certain

functions and accessories may require it to run manually

and the correct speed must then be set.

This automatic control occurs when the compressor is

running and sets the speed of the heating medium

pump, for the present operating mode, to obtain the

optimal temperature difference between the supply and

return lines. During heating operation, the set DOT (di-

mensioned outdoor temperature) and temperature dif-

ferential in menu 5.1.14 are used. If necessary, the max-

imum speed of the circulation pump can be limited in

menu 5.1.11.

35

Chapter 6 |

Commissioning and adjusting

GreenMaster-HP